Dual-mode plug nozzle

A nozzle and center body technology, which is applied in the field of nozzles with variable geometry, can solve the problem that the nozzle cannot obtain the geometric shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

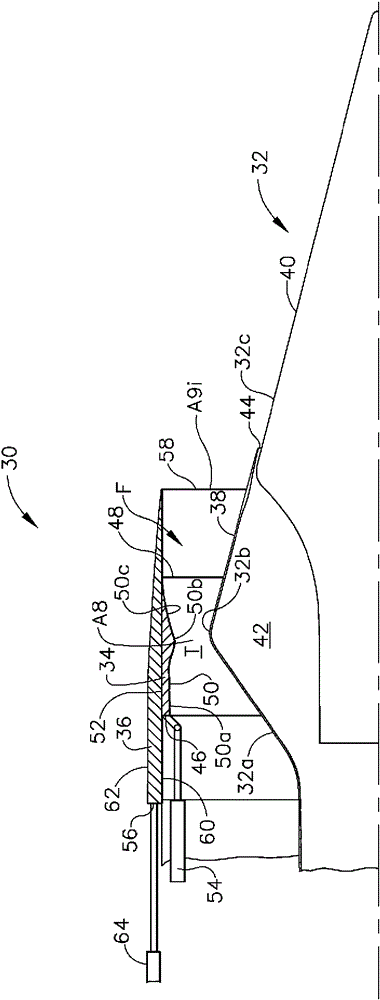

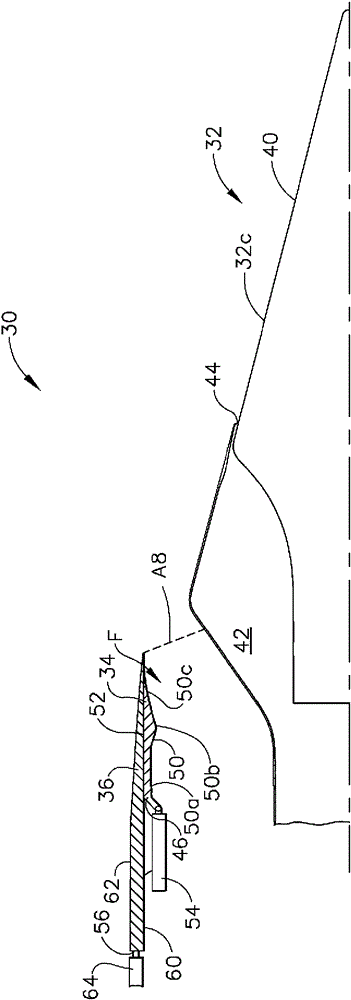

[0024] Now, reference will be made in detail to the provided embodiments, and one or more examples of these embodiments are illustrated in the drawings. Examples are provided through explanations of the disclosed embodiments, not limitations. This embodiment is applied to gas turbine engines, such as aviation, power generation, industry, or ships. In the gas turbine engine, the combustor burns fuel, and for the gas turbine engine, the operation of the aircraft under the supersonic flight mechanism is expected. The embodiments herein utilize current plug nozzle technology including the use of existing linear actuators. The embodiments provide the ability to further optimize nozzle performance under all flight conditions.

[0025] This embodiment relates to an engine for a supersonic aircraft. Specifically, an engine intended for operation during supersonic flight requires large variability with respect to nozzle throat area (A8), nozzle exit area (A9), and area ratio (A9 / A8) (di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com