Boring method of metal substrate and detection method of hole diameter

A technology of metal substrate and drilling method, which is applied in the field of circuit board manufacturing, can solve the problems of inability to verify missing or wrong drilling, and inconvenient measurement of hole diameter, so as to optimize the method of measuring hole diameter, reduce human resources and production time, and test the effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings and specific embodiments:

[0020] The metal substrate drilling method of the present invention mainly includes the following steps:

[0021] (1) Combine the metal substrate single boards to form a large board;

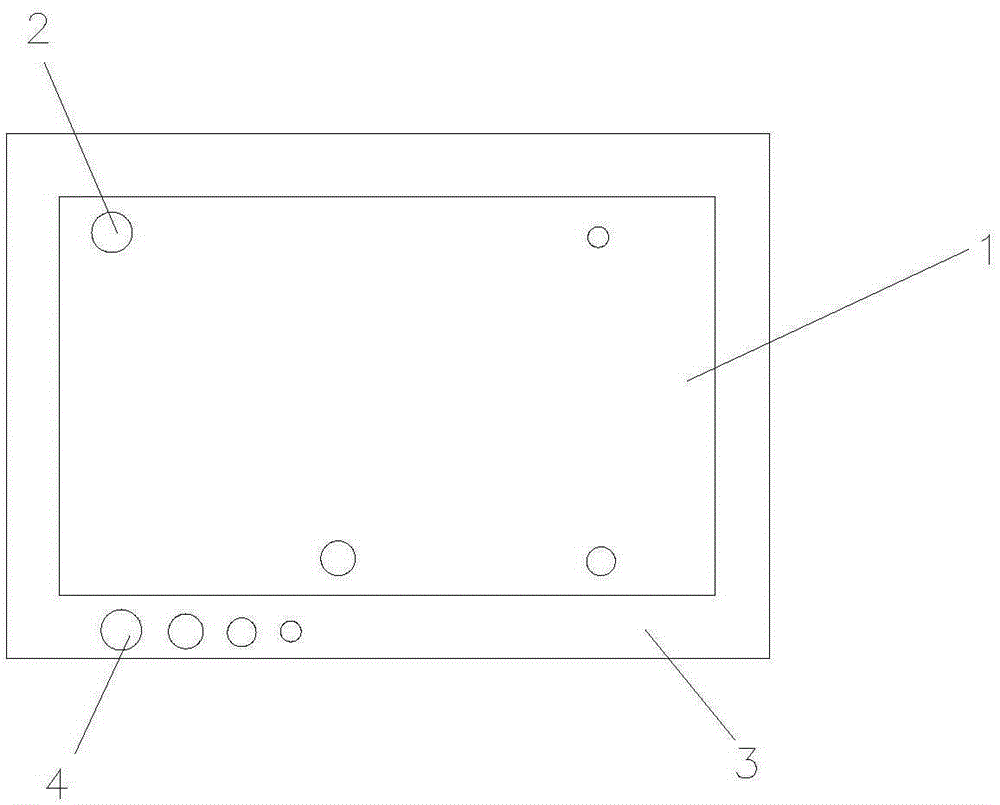

[0022] (2) According to the size of the aperture, drill a working hole 2 of one aperture in the effective unit 1 of the jigsaw, and then drill a detection hole 4 of the same aperture in the process edge 3. For example, such as figure 1 As shown, there are a total of four kinds of holes to be drilled. According to the order of hole diameter from large to small or from small to large, first drill the working hole 2 of the first type in the effective unit 1, and then drill the first type of hole in the process side 3. Detect hole 4, then use the same method to drill the second type of aperture 2 and test hole 4 successively, the remaining aperture is also the same operation, and fina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com