A fully automatic thick-diameter inductance winding machine

A fully automatic, winding machine technology, applied in the direction of inductance/transformer/magnet manufacturing, circuits, electrical components, etc., can solve the problems of unstable inductance quality, unstable quality, lack of labor, etc., and achieve stable product quality and long service life Long, productive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

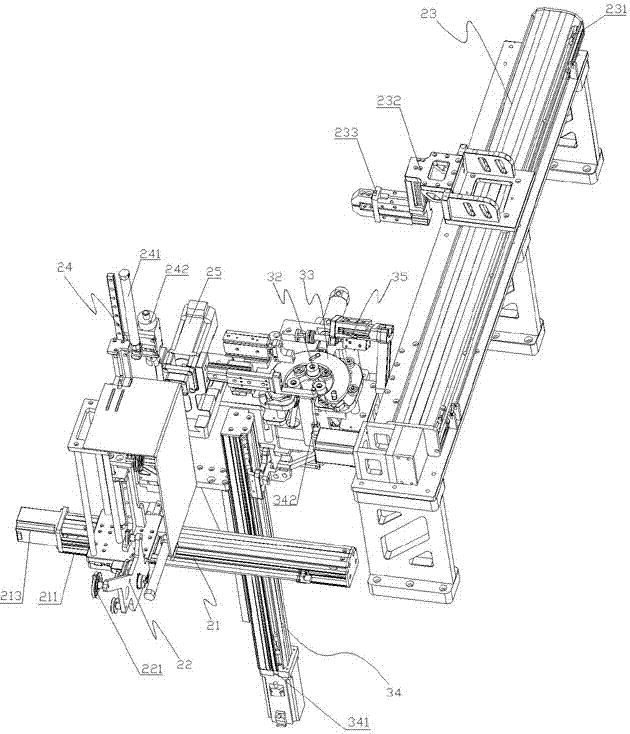

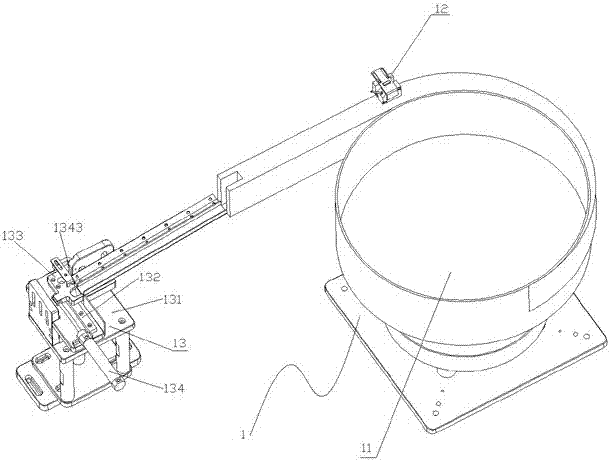

[0033] Such as Figure 1 to Figure 8 Shown, a kind of automatic thick wire diameter inductance winding machine of the present invention, it is provided with:

[0034] Magnetic ring feeding system 1, which is provided with a vibrating plate 11 with a discharge port, a screening device 12 installed on the vibrating plate 11 and a positioning device 13 located at the position of the discharge port of the vibrating plate 11;

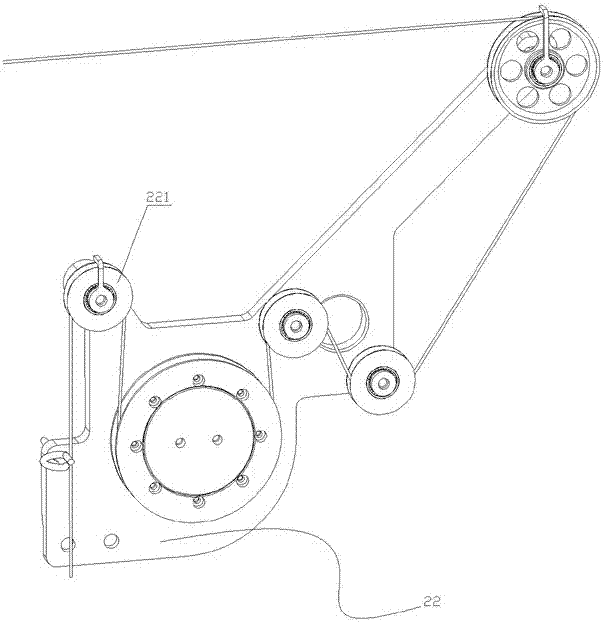

[0035] A pay-off system 2, which is provided with a tensioner 22, a wire pulling device 23 and a wire cutting device 24;

[0036] Winding system 3, which is provided with an assembly station 31, a magnetic ring rotating device 32 for adjusting the angle of the magnetic ring is provided at the lower end of the assembly station 31, and a magnetic ring for clamping the magnetic ring is provided at the upper end of the assembly station 31 A clamping device 33, a thread hooking device 34 located next to the assembly station 31, and a thread clamping and turning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com