CNC winding machine

A technology of a numerically controlled winding machine and a winding needle, which is applied in the mechanical field, can solve problems such as low efficiency, and achieve the effects of high efficiency, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

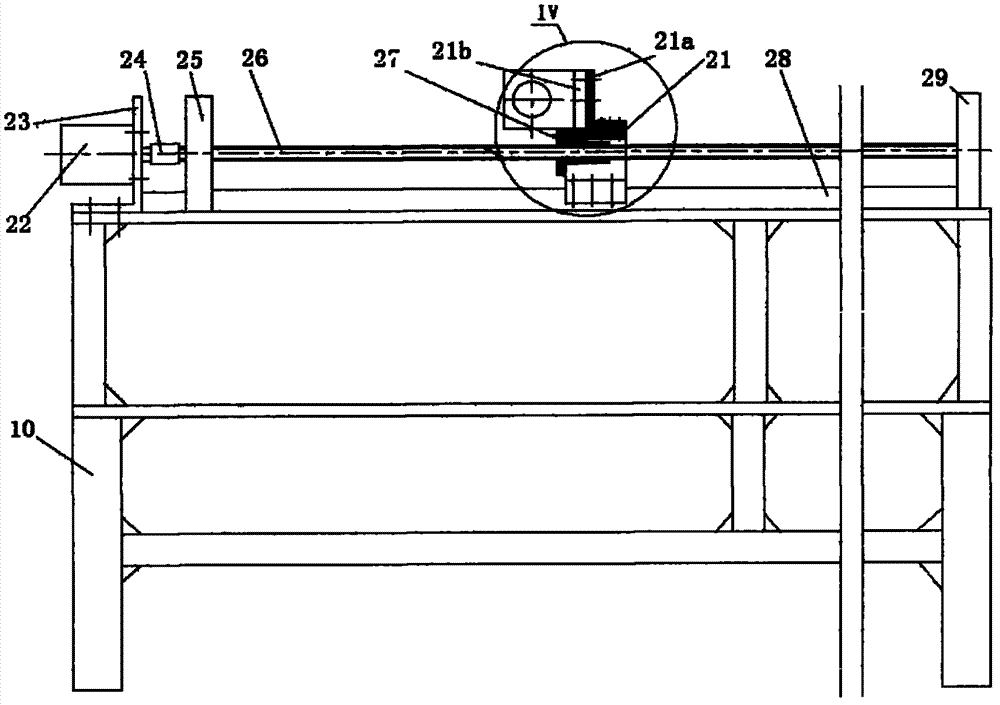

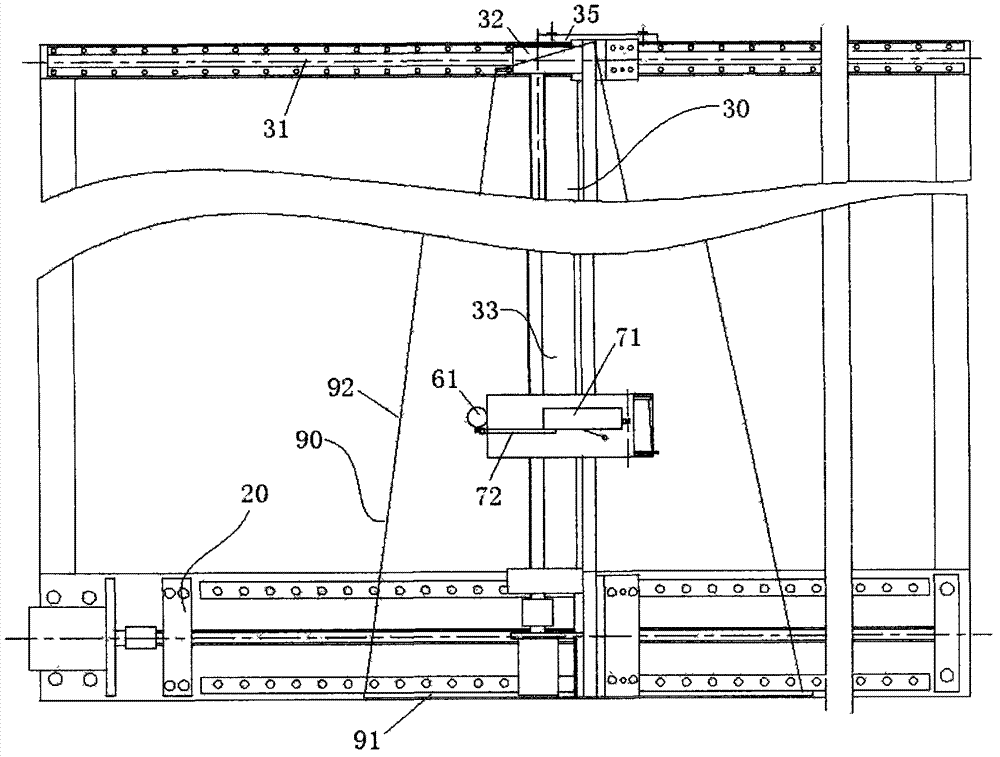

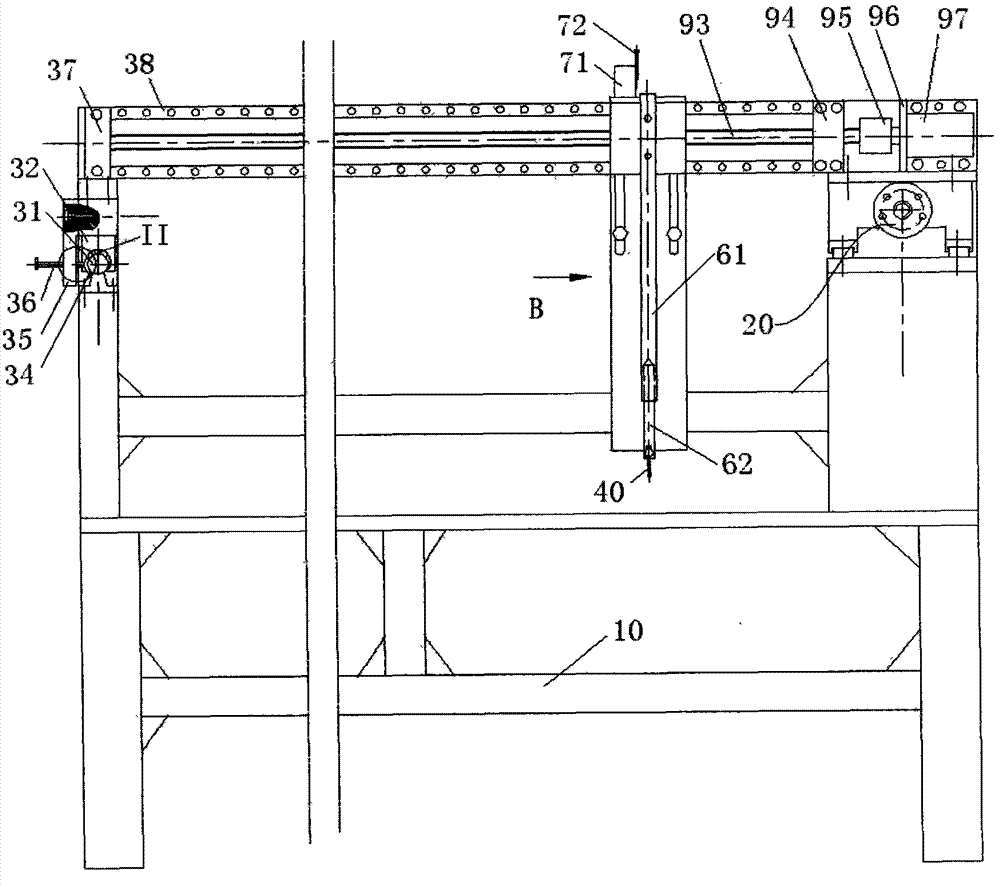

[0027] The present invention can be used to realize automatic winding of metal wires on a plane, which uses numerical control to control the servo motors of the X-axis and Y-axis to rotate at a certain speed, thereby driving the corresponding ball screw to rotate, which is realized through the cooperation of the screw and the nut The conversion of the linear motion drives the winding needle 40 to move according to the specified position coordinates, so as to realize the automatic winding of the metal wire and improve the production efficiency. The winding format of the present invention can reach 2800mmx1800mm, and in one embodiment, the size of the equipment is 3300mmx2300mmx1700mm.

[0028] Please refer to Figure 1 to Figure 3 As shown, the nume...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com