Stable rapid atmosphere switching method, system and application

A fast switching and atmosphere technology, which is applied in the field of fluid control technology and chemical analysis, can solve the problems that affect the reliability, repeatability and accuracy of the analysis process, and the reversing valve system cannot replace the atmosphere in the microreactor smoothly and quickly. , to achieve rapid replacement, promote development, and avoid dead volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

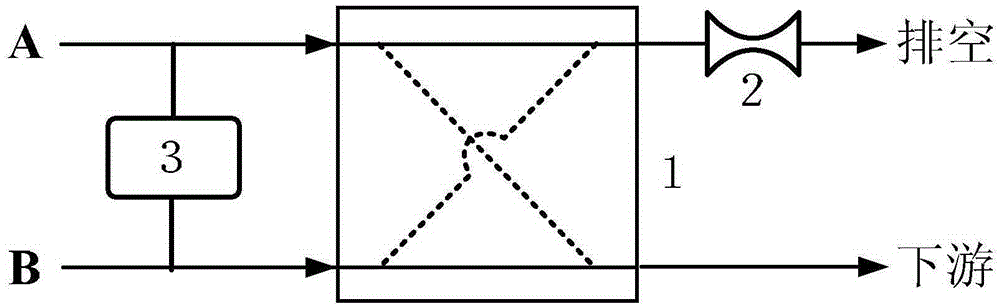

[0016] Specific implementation plan one: combine figure 1 Describe this embodiment. This embodiment provides a method and system for switching atmospheres smoothly and quickly. The airflows A and B are connected to the outlet airflow and exhaust airflow through simple pipelines and the airflow reversing unit 1 composed of one or more two-position direct-acting solenoid valves; the two inlet airflows A and B flow continuously and stably Inlet airflow reversing unit 1, airflow reversing unit 1 switches two inlet airflows (A, B), respectively forms outlet airflow and exhaust airflow according to timing settings, and realizes fast switching of airflow; uses pressure transmitter to detect two inlet airflows Use the inlet pressure controller to adjust the back pressure of the exhaust air flow, so that the pressure states of the two intake air streams A and B are the same, so that during the air flow switching process, the two intake air streams A, B The pressure and flow of B are s...

specific Embodiment approach 2

[0019] Specific implementation plan two: combine figure 1 This embodiment will be described. In this embodiment, the effective diameter of the flow channel in the switching system is 1 mm to 4 mm. Such setting reasonably increases the airflow velocity and makes the flow in the tube more similar to plug flow, so the residual airflow in the tube after switching can be slowed down, thereby speeding up the speed of atmosphere switching, and it is easy to manufacture and use. The other components and connections of this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

[0020] Specific implementation plan three: combination figure 1 Describe this embodiment. In this embodiment, the differential pressure value of the pressure transmitter 3 is stabilized at -100Pa to 100Pa. Negative feedback is automatically adjusted to achieve. With this setting, the pressure difference between the intake airflow (A, B) is intelligently controlled to be close to zero; the disturbance range of the pipeline state parameters such as pressure and flow at the moment of switching is minimized, so that the atmosphere quickly stabilizes to the target state after switching, so that The reliability, repeatability and accuracy of atmosphere switching are greatly improved; and it is easy to operate and use. The other components and connections of this embodiment are the same as those of Embodiment 1 or Embodiment 2.

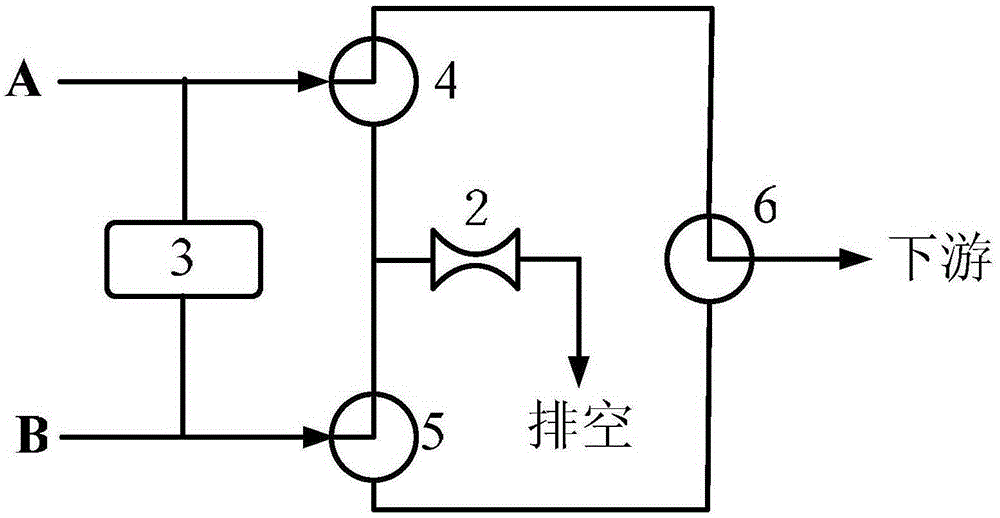

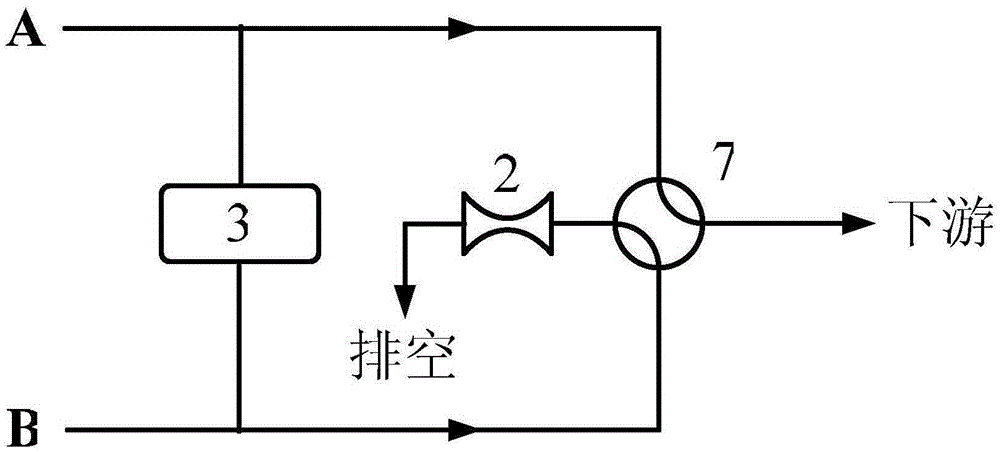

[0021] Specific implementation plan four: combination figure 1 and figure 2 To illustrate this embodiment, the airflow reversing unit of this embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com