On cell automatic electrical-testing equipment

A kind of electrical measurement equipment and equipment technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of high defect rate of panel oncell electrical measurement, low accuracy of panel identification recognition, and poor positioning of artificial panels, etc., to achieve The effect of improving production yield, excellent overall structure and stable equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

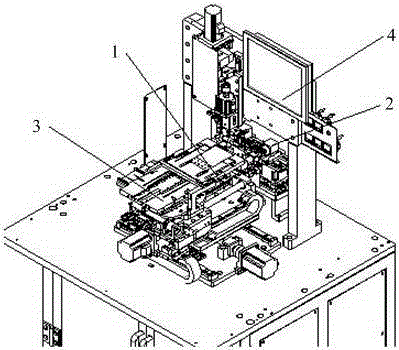

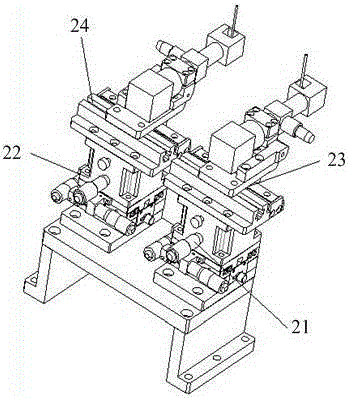

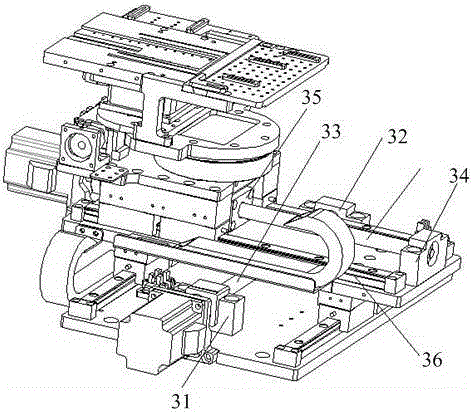

[0026] ginseng Figure 1 to Figure 5 as shown, figure 1 It is a structural diagram of the equipment core in the Oncell automatic electrical measuring equipment of the present invention; figure 2 It is a structural diagram of a panel visual processing system in the core of the device of the present invention; image 3 It is a structural diagram of the panel pressing and correcting mechanism in the core of the equipment of the present invention; Figure 4 It is the structural diagram of the preloading mechanism in the equipment core of the present invention; Figure 5 It is the overall structure diagram of the Oncell automatic electric measuring equipment of the present invention.

[0027] figure 1 It is the equipment core of the Oncell automatic electrical measuring equipment of the present invention, including: a panel load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com