Fall-back stop mechanism for super-large dropping device

A stop mechanism, super-large technology, applied in the direction of measuring devices, machine/structural component testing, impact testing, etc., can solve accidental injuries, time-consuming and labor-intensive problems, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

[0034] In order to facilitate the description of the specific structure of the fall-back stop mechanism of the present invention, the preferred structure of the super-large drop device of the present invention is first described here, specifically as follows:

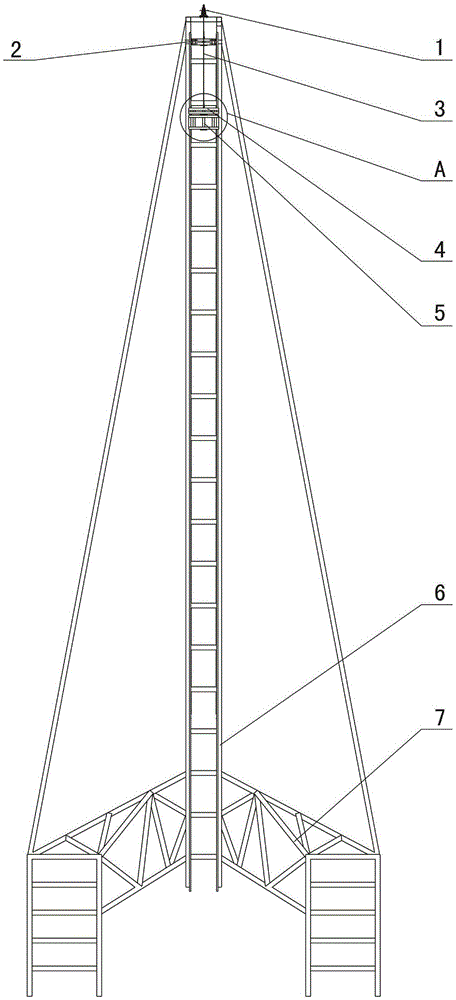

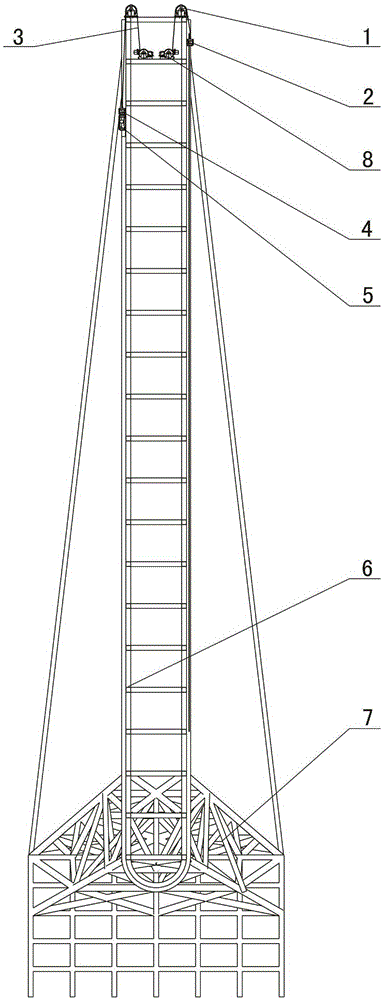

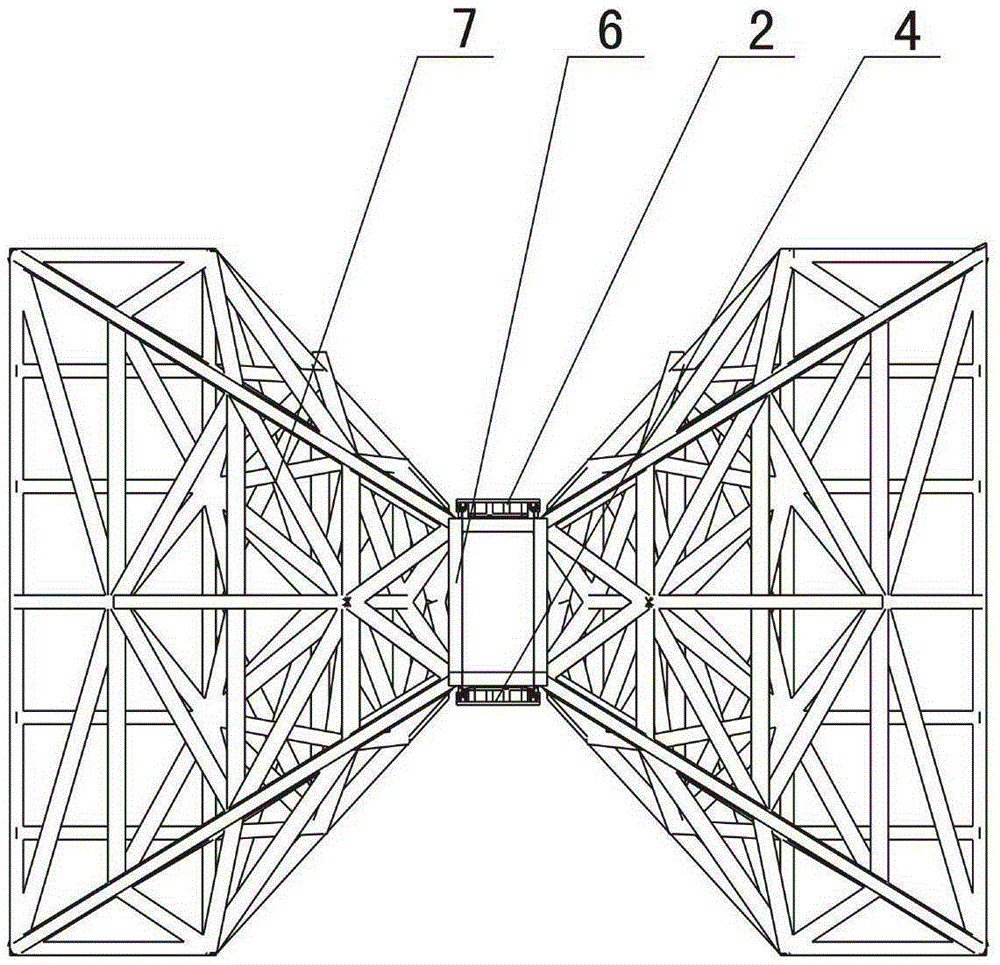

[0035] Such as Figure 1-Figure 4 As shown, the preferred super-large drop device includes a drop tower 7, a track 6, and a product test vehicle 5 for placing and driving a test product, a traction lifting trolley 4, a traction slow-falling trolley 2, an electromagnet gripper 9a, an electromagnetic The iron suction plate 9b and the fall-back stop device, the track 6 is installed on the drop tower 7, the product test vehicle 5 is installed on the track 6, and the bottom of the track 6 is "U" shaped, and the product test vehicle 5 is initially installed on the track 6 The vertical section is the first section of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com