Method and device for calibrating a pressure sensor

A pressure sensor, calibration equation technology, applied in the direction of measurement device, force/torque/work measurement instrument calibration/test, measurement of fluid pressure, etc. The effect of good calibration accuracy and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

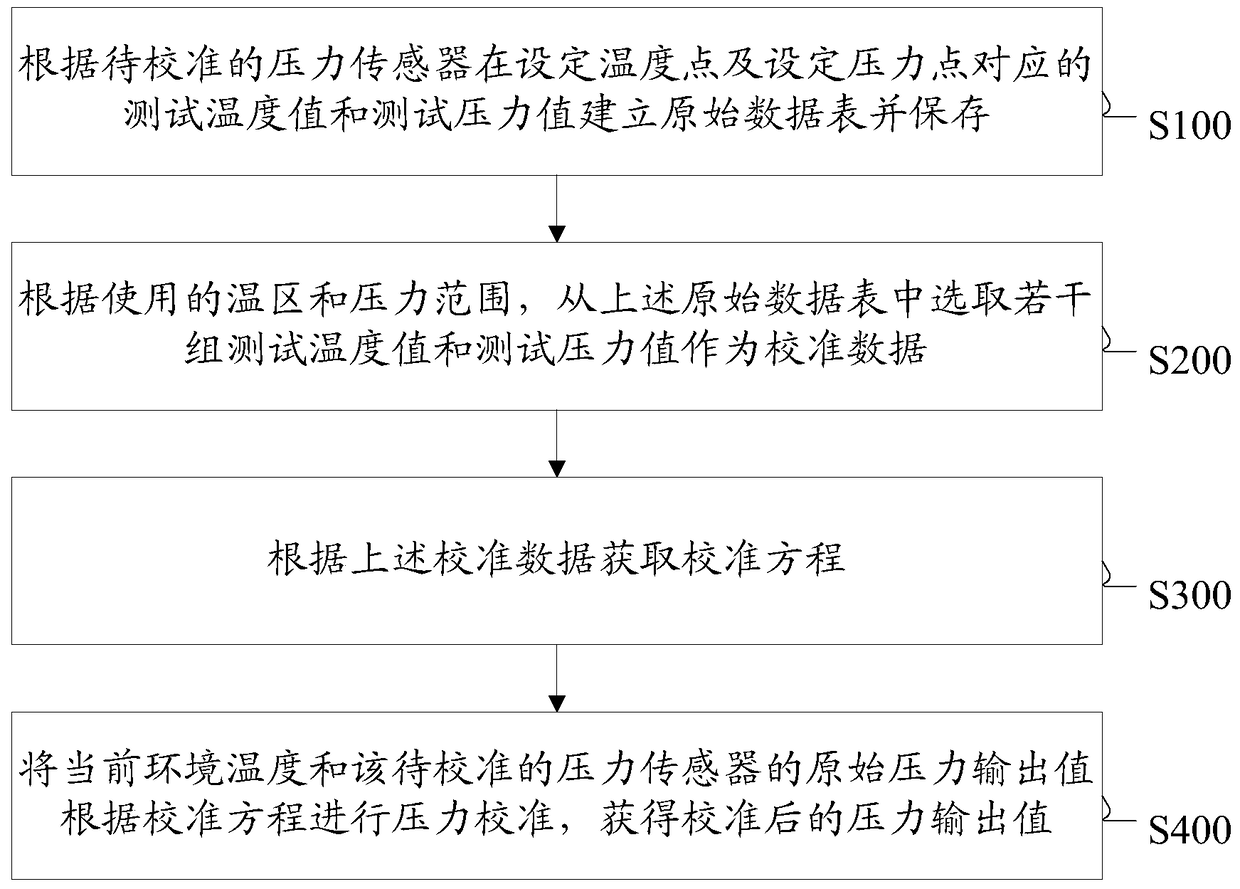

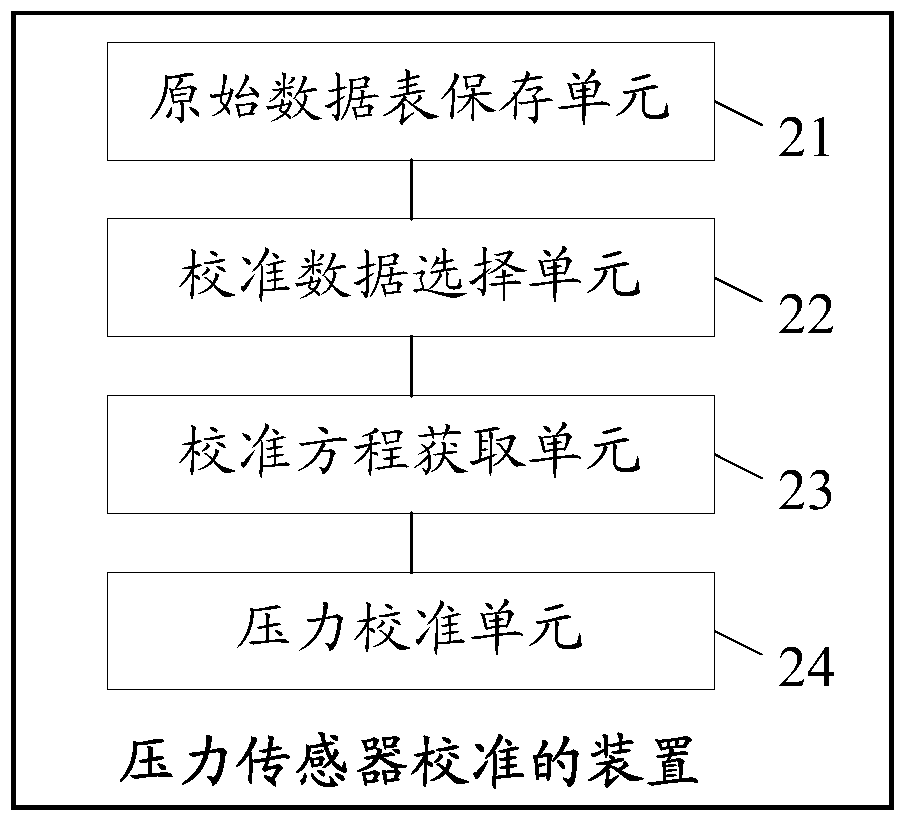

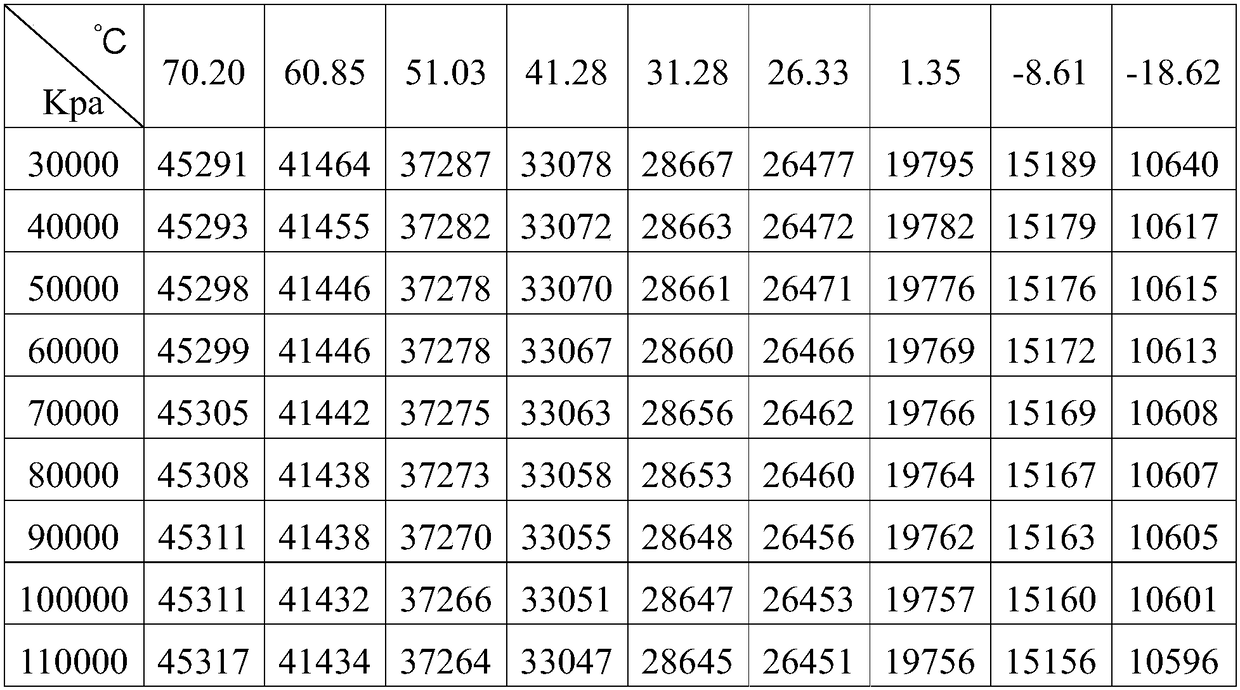

[0042] The overall design idea of the present invention is: save the test temperature value and test pressure value corresponding to the set temperature point and set pressure point of the pressure sensor to be calibrated as the original data table, and the user can use it according to the temperature zone used in the original data table. In the data table, several groups of test temperature values and test pressure values are selected as calibration data, and corresponding calibration equations are established according to the calibration data, so that the current ambient temperature and the original pressure output value of the pressure sensor to be calibrated can be passed through the corresponding The calibration equation performs pressure calibration to obtain the calibrated pressure output value.

[0043] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com