A High Stability Electromagnetic Heating Reactor Rotary Kiln

A heating reaction kettle, high stability technology, applied in lighting and heating equipment, rotary drum furnace, furnace, etc., can solve the problems that are not easy to realize, complicated hematite beneficiation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

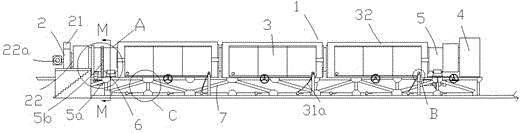

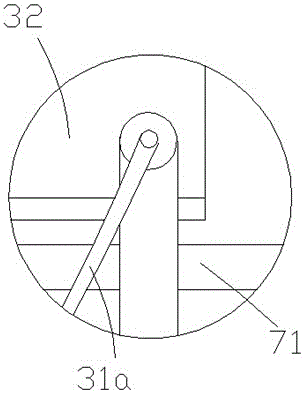

[0027] A high-stability electromagnetic heating reaction kettle rotary kiln of the present invention includes a kiln body 1. The kiln body 1 is provided with a feeding part 2, a heating part 3 and a discharging part 4 in sequence from front to back, and the feeding part 2 is provided with The feed port 21 and the feed pipe 22. The front end of the feed pipe 22 communicates with the feed port 21. The rear end of the feed pipe 22 is connected to the heating part 3, and the heating part 3 is provided with a heating part shell 32 for heating An axially extending barrel 5 penetrates through the housing 32. After the mineral material is output from the feeding pipe 22, it enters the barrel 5. The barrel 5 includes a hollow barrel housing 51, and the barrel housing 51 is provided with There is an axially extending energy storage mandrel 52. The energy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com