Combined cooling heating and power system driven by low-grade waste heat

A low-grade technology of cogeneration of cooling, heating and power, applied in the direction of heating and cooling combination, machines using waste heat, refrigerators, etc., can solve the problems of insufficient simplification of the process, easy loss of energy, and increased number of components, etc., to achieve equipment reduction and high efficiency Effects of recycling and system process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

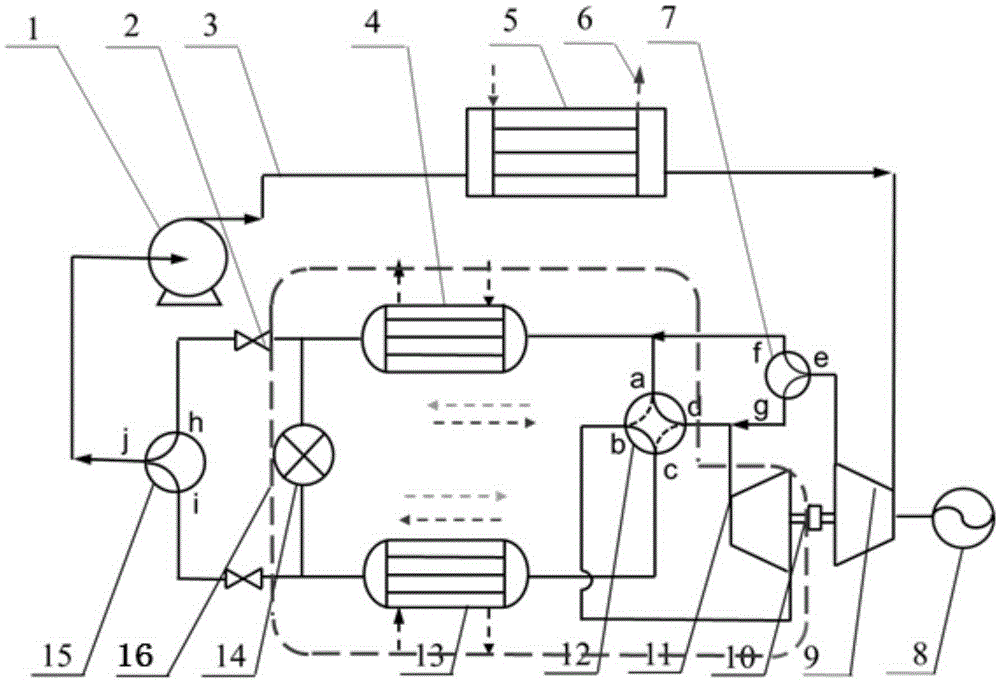

[0030] A low-grade waste heat-driven combined cooling, heating and power generation system, its structure is as follows figure 1As shown, it includes an organic Rankine cycle unit. The organic Rankine cycle unit is composed of a working medium pump 1, an evaporator 5, an expander 9, and a built-in heat pump cycle unit 16 that are sequentially connected to form a cycle. The built-in heat pump cycle unit 16 includes a cycle The connected compressor 11, the first heat exchanger 4, the throttle valve 14 and the second heat exchanger 13 are also provided with the compressor 11, the first heat exchanger 4 and the second heat exchanger respectively in the circulation pipeline of the heat pump. The four-way reversing valve 12 connected to the heat exchanger 13, the evaporator 5 connected to the waste heat flow 6, the first heat exchanger 4 and the second heat exchanger 13 respectively connected to the external heat exchange flow to exchange heat, the output work of the expander 9 The ...

Embodiment 2

[0037] A low-grade waste heat-driven combined cooling, heating and power generation system, the structure of which can be found in figure 1 As shown, it includes an organic Rankine cycle unit. The organic Rankine cycle unit is composed of a working medium pump 1, an evaporator 5, an expander 9, and a built-in heat pump cycle unit 16 that are sequentially connected to form a cycle. The built-in heat pump cycle unit 16 includes a cycle The connected compressor 11, the first heat exchanger 4, the throttle valve 14 and the second heat exchanger 13 are also provided with the compressor 11, the first heat exchanger 4 and the second heat exchanger respectively in the circulation pipeline of the heat pump. The four-way reversing valve 12 connected to the heat exchanger 13, the evaporator 5 connected to the waste heat flow 6, the first heat exchanger 4 and the second heat exchanger 13 respectively connected to the external heat exchange flow to exchange heat, the output work of the expa...

Embodiment 3

[0044] A low-grade waste heat-driven combined cooling, heating and power generation system, the structure of which can be found in figure 1 As shown, it includes an organic Rankine cycle unit. The organic Rankine cycle unit is composed of a working medium pump 1, an evaporator 5, an expander 9, and a built-in heat pump cycle unit 16 that are sequentially connected to form a cycle. The built-in heat pump cycle unit 16 includes a cycle The connected compressor 11, the first heat exchanger 4, the throttle valve 14 and the second heat exchanger 13 are also provided with the compressor 11, the first heat exchanger 4 and the second heat exchanger respectively in the circulation pipeline of the heat pump. The four-way reversing valve 12 connected to the heat exchanger 13, the evaporator 5 connected to the waste heat flow 6, the first heat exchanger 4 and the second heat exchanger 13 respectively connected to the external heat exchange flow to exchange heat, the output work of the expa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com