A negative pressure fan with self-cleaning function

A negative pressure fan, functional technology, applied in home appliances, space heating and ventilation details, household heating, etc., can solve the problems of fan damage, increase the workload of employees, etc., to improve firmness, safety, and solve Difficult to clean up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

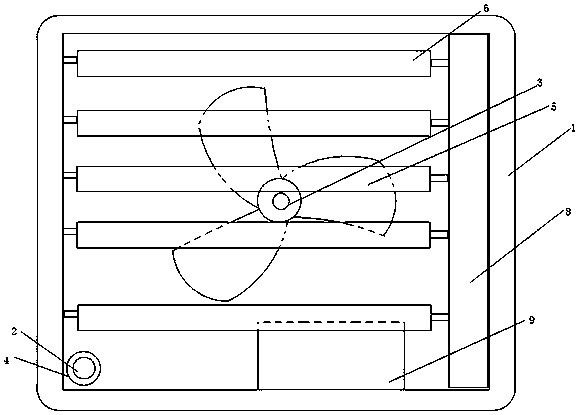

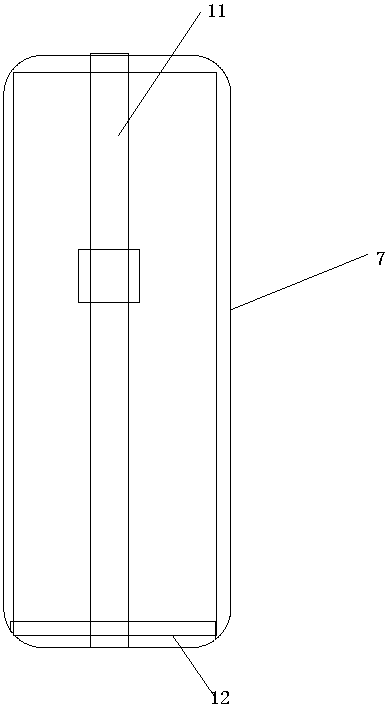

[0030] Such as figure 1 and figure 2 The shown negative pressure fan with self-cleaning function includes: housing 1, motor 2, rotating shaft 3, pulley 4, fan blade 5, deflector 6, casing 7, electrostatic precipitator 8 and control device 9 , The electrostatic precipitator 8 is composed of an anode plate, a cathode plate, a rectifier, a dirt bag and a controller.

[0031] The relationship between the above components is as follows:

[0032] The motor 2 is arranged below the casing 1, the rotating shaft 3 is arranged on a support plate in the middle of the casing 1, a turntable is arranged on the support plate, and the pulley 4 is arranged on the motor 2. The fan blade 5 is arranged on the rotating shaft 3, the deflector 6 is movably connected to both sides of the casing 1, the casing 7 is fixed on the casing 1, and the electrostatic precipitator 8 is located in the housing 1, the motor 2 and the electrostatic precipitator 8 are connected to the control device 9, the pulley...

Embodiment 2

[0042] The structure of the negative pressure fan with self-cleaning function in the working method of the negative pressure fan with self-cleaning function described in this embodiment is the same as that in Embodiment 1.

[0043] In this embodiment, a working method of a negative pressure blower with self-cleaning function, the specific working method is as follows:

[0044] (1): First connect the negative pressure fan to the power supply, and then the negative pressure fan will enter the working state;

[0045](2): After the power is turned on, the motor 2 starts to rotate, and the pulley 4 is set on the motor 2, so the pulley 4 rotates with the motor 2;

[0046] (3): During the rotation of the pulley 4, since the pulley 4 and the turntable are connected by a belt, the turntable will also rotate continuously under the drive of the pulley 4;

[0047] (4): During the rotation of the turntable, it will drive the rotating shaft 3 to rotate together. Since the fan blade 5 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com