Electric pole pull wire fastening winder

A utility pole and winder technology, applied in the field of electric construction equipment, can solve the problems of unsatisfactory winding effect of the pull wire, inconvenient winding by workers, unguaranteed quality, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

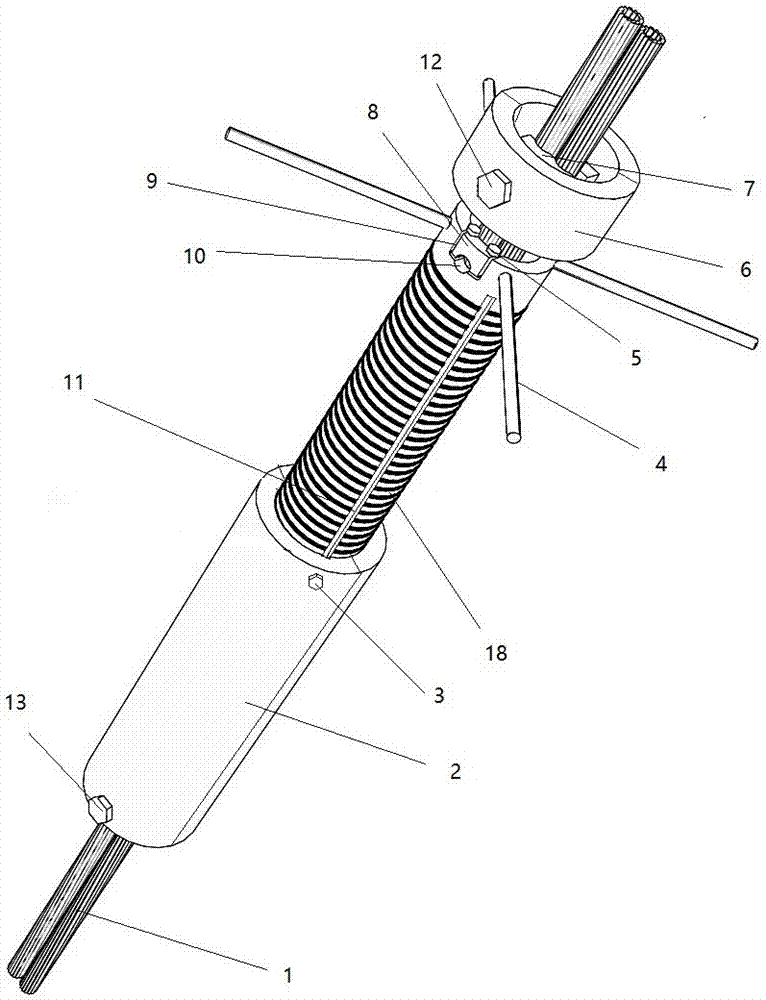

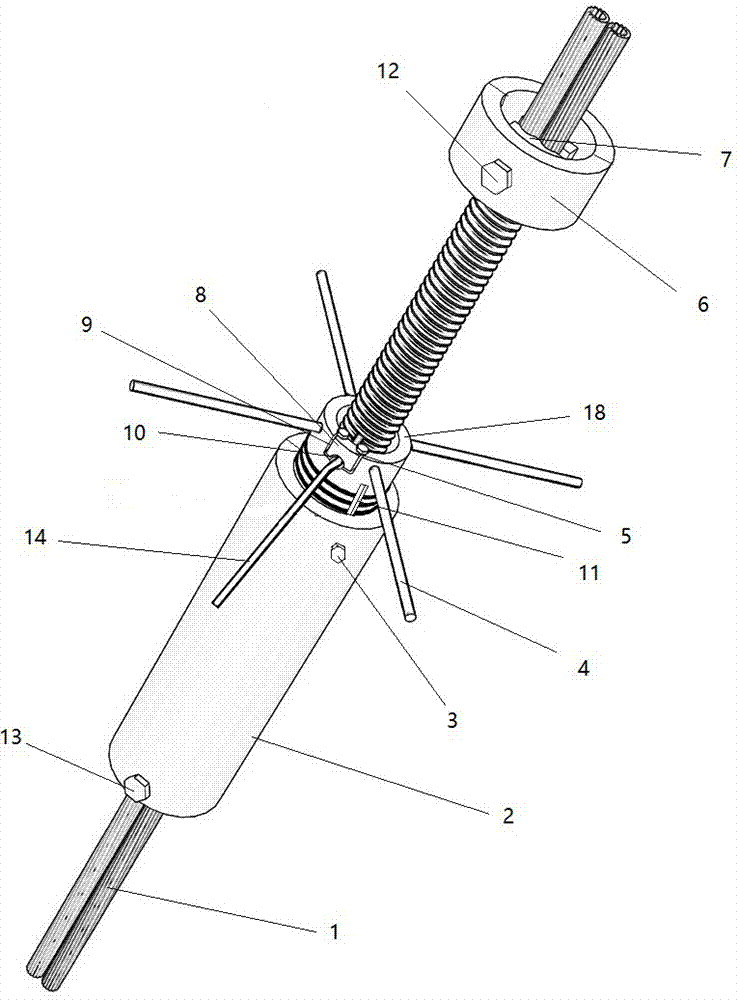

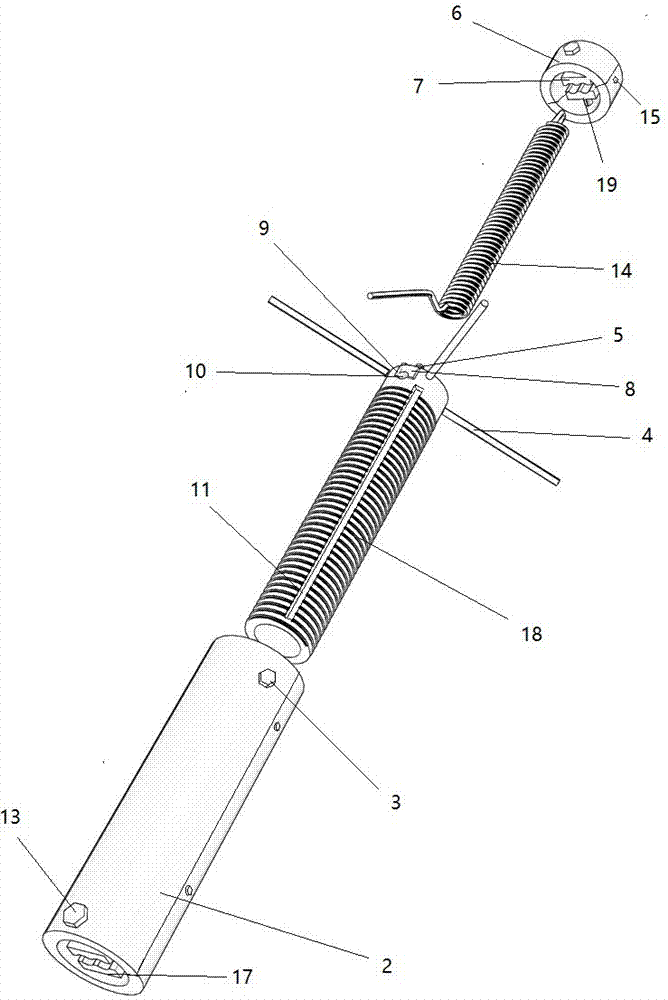

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0014] Such as Figure 1-3 As shown, the wire pole fastening winder includes an outer casing 2, and the outer casing 2 is set on the steel strand 1; an A hoop 17 is arranged inside the lower end of the outer casing 2, and the A hoop 17 includes two gaskets 7, There are arc-shaped grooves 16 corresponding to the positions of the two steel strands 1 on the gasket 7, and the outer side of each gasket 7 is provided with a jacking bolt 13 installed on the side wall of the outer casing 2; the inner wall of the outer casing 2 is threaded Connected with an inner sleeve 18, the upper end of the inner sleeve 18 is provided with a groove 9, the groove 9 is connected with a pressure block 8 through a bolt 5, and the bottom of the groove 9 and the bottom of the pressure block 8 are all opened on the contact surface. There are half holes 10; bindi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com