Environment-friendly and energy-saving plastic shell cement quadrel

An environmental-friendly, energy-saving, and cement-based technology, which is applied to roads, pavements paved with prefabricated blocks, and pavement details, can solve problems such as uneven roads, rough cement surfaces, and low service life, and achieve smooth and beautiful road surfaces with high toughness and strength. , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

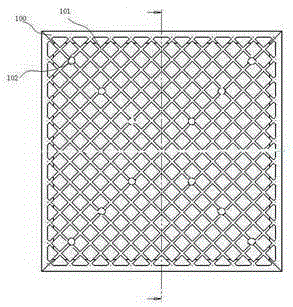

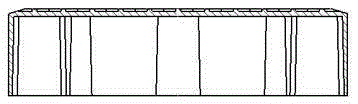

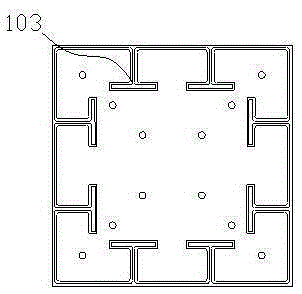

[0028] refer to Figure 1-3 As shown, an environment-friendly and energy-saving molded shell cement square brick includes a plastic shell 100 filled with cement, and the adjacent plastic shells 100 are seamlessly connected, and the plastic shell 100 100 is provided with reinforcing ribs 103, and the reinforcing ribs 103 are set in a T shape. Eight reinforcing ribs 103 are arranged and evenly distributed on the four sides of the plastic housing 100. The surface of the plastic housing 100 Anti-slip lines 101 are provided on the plastic shell 100 , and the anti-slip lines 101 are arranged in a net shape. More than one leak hole 102 is provided and evenly distributed on the plastic shell 100 .

[0029] The sizes of the leakage holes 102 are consistent.

[0030] The dimensions of the plastic housings are 200mm*200mm, 200mm*100mm and 100mm*100mm respectively, which can be adapted to more places of use.

[0031] An environment-friendly and energy-saving method for using plastic she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com