A Method for Determining Process Parameters of Refined Asphalt Prepared by Solvent Method Using Phase Diagram

A technology for refining asphalt and process parameters, which is applied in the processing of tar asphalt/petroleum asphalt/natural asphalt, processing tar asphalt/petroleum asphalt/natural asphalt by distillation, and processing tar asphalt/petroleum asphalt/natural asphalt by selective extraction, etc. It can solve the problems of heavy test workload and low optimization precision, and achieve the effect of smooth production operation and improved economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

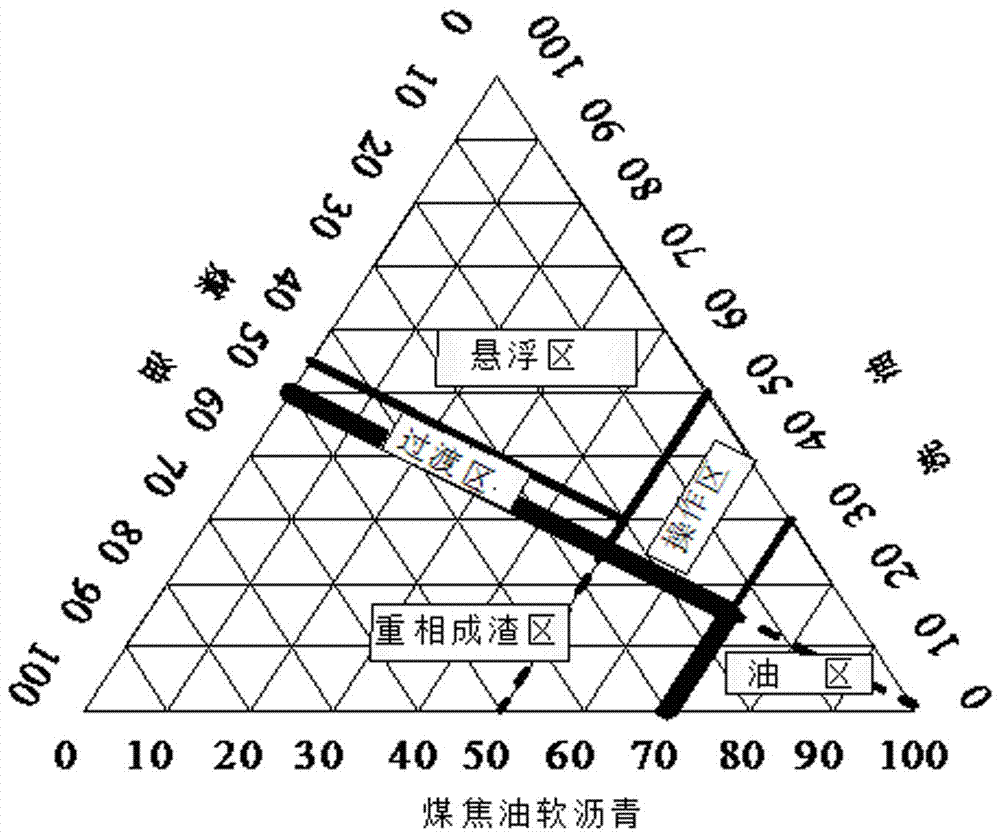

[0026] The pitch used is coal tar soft pitch; the aliphatic solvent used is kerosene; the aromatic solvent used is light washing oil;

[0027] Mix asphalt with a mixed solvent. The mixed solvent is composed of an aromatic solvent and an aliphatic solvent. In the mixed solution after mixing, the mass ratio of the aromatic solvent, the aliphatic solvent and the asphalt is 1: (0.125~1): (0.125~8);

[0028] Heat the mixed solution to 60°C and start stirring. When the temperature rises to 120°C, keep it warm and continue to stir for 30 minutes, then stop stirring, and settle at 120°C for 2 hours; the upper layer of the material after the settlement is taken out as the light phase, and the rest as the heavy phase. The mass ratio of the light phase to the heavy phase is 1:0.55; observe the flow state of the heavy phase, whether the heavy phase is poured smoothly, whether it is viscous, whether there are solids in the heavy phase residue, and whether there are lumps Phenomena such as...

Embodiment 2

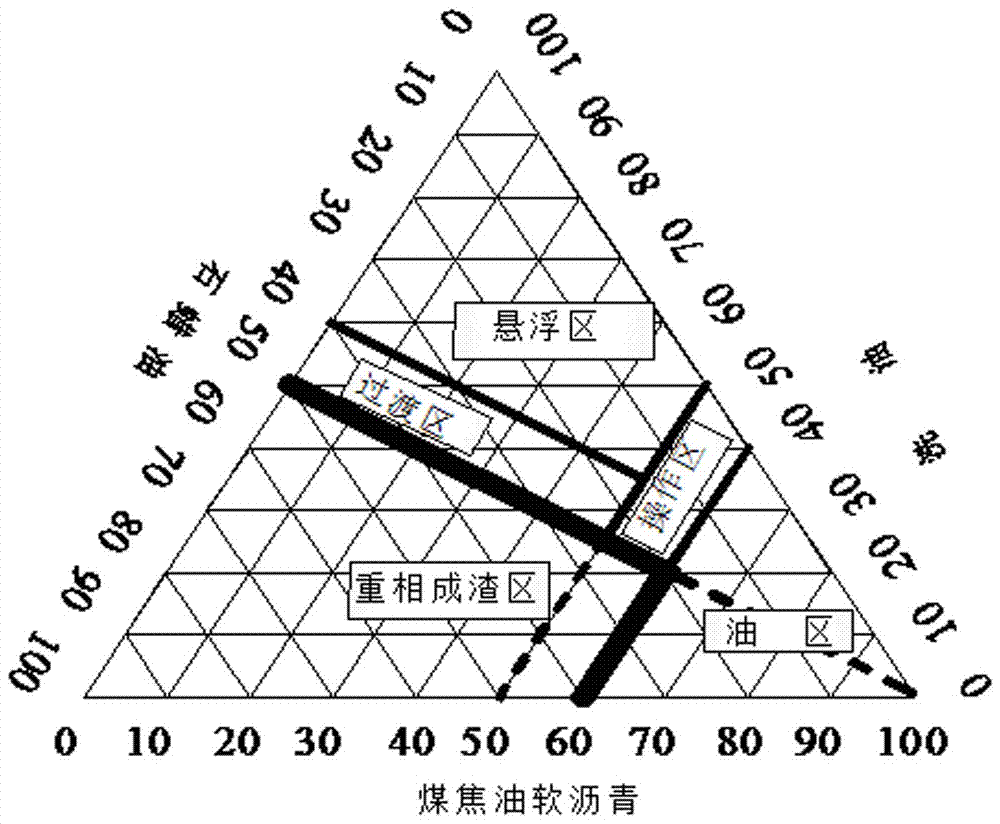

[0040] Method is with embodiment 1, and difference is:

[0041] (1) The bitumen used is coal tar soft pitch; the aliphatic solvent used is paraffin oil; the aromatic solvent used is light washing oil;

[0042] (2) Heat the mixed solution to 80°C and start stirring. When the temperature rises to 100°C, keep it warm and continue stirring for 40 minutes, then stop stirring, and settle at 100°C for 5 hours; the mass ratio of light phase to heavy phase is 1:0.35;

[0043] (3) Obtain 26 sets of experimental data;

[0044] (4) The proportioning ratio of each substance in the experiment is shown in Table 2;

[0045] Table 2

[0046] Test No.

Paraffin oil / %

Washing oil / %

1

30

40

30

2

40

30

30

3

30

40

30

4

65

15

20

5

50

20

30

6

20

20

60

7

20

20

60

8

80

10

10

9

10

10

80

10

60

30

10

11

7...

Embodiment 3

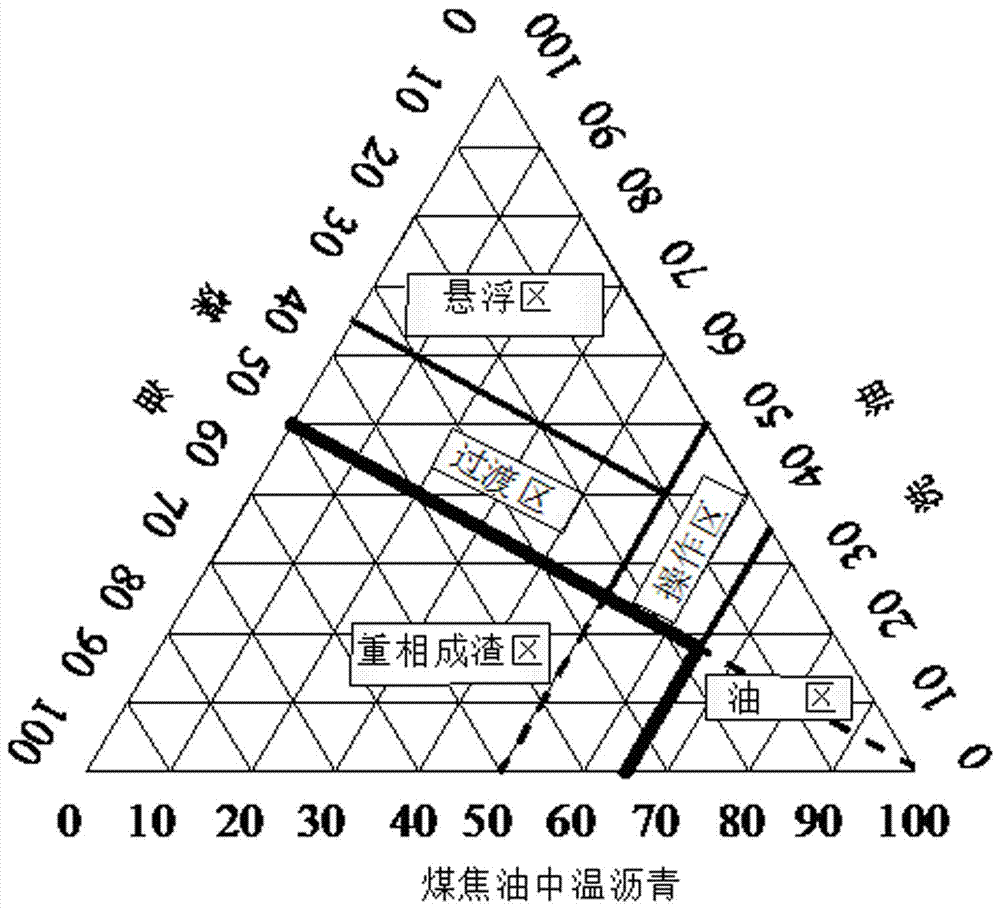

[0050] Method is with embodiment 1, and difference is:

[0051] (1) The pitch used is coal tar medium temperature pitch; the aliphatic solvent used is kerosene; the aromatic solvent used is light washing oil;

[0052] (2) Heat the mixed solution to 100°C and start stirring. When the temperature rises to 150°C, keep it warm and continue stirring for 20 minutes, then stop stirring, and settle at 150°C for 1 hour; the mass ratio of the light phase to the heavy phase is 1:1;

[0053] (3) Obtain 25 sets of experimental data;

[0054] (4) The proportioning ratio of each substance in the experiment is shown in Table 3

[0055] table 3

[0056] Test No.

[0057] Depend on image 3 The scope of the operation area can be seen: when the ratio of coal tar medium-temperature asphalt is between 50-60%, the ratio of washing oil is between 20-30%, and the ratio of kerosene is between 15-20%, the process operation parameters aromatic hydrocarbon solvent and fat The mass ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com