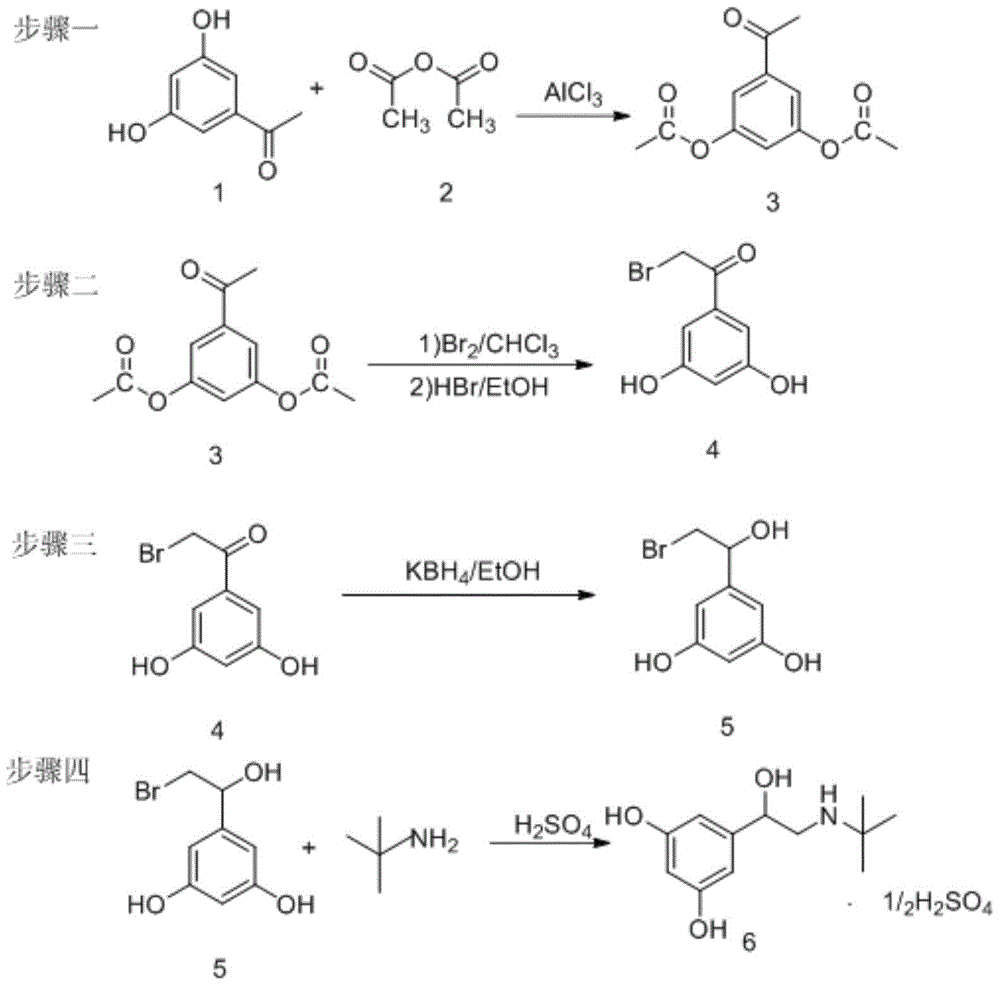

A kind of preparation method of terbutaline sulfate

A technology of terbutaline sulfate and acetic anhydride, which is applied in the preparation of amino compounds from amines, bulk chemical production, organic chemistry, etc., can solve the problems of high cost, achieve low cost, high yield, and avoid the effect of hydrogenation high pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation method of terbutaline sulfate, concrete steps comprise:

[0024] (1) Dissolve 3,5-dihydroxyacetophenone (1.52Kg, 10mol) in 10L of dichloromethane under nitrogen protection, add acetic anhydride (2.04Kg, 20mol), cool down to 20°C, and add trichloride in batches Aluminum (2.67kg, 20mol), the temperature is controlled between 20-25°C, the addition is completed in 2h, and the reaction is carried out at 20°C for 0.5h. After the reaction was completed, 10L of water was slowly added, stirred for 15min, allowed to stand for stratification, and the organic phase of the lower layer was washed with 10L of water once, and dichloromethane was evaporated under reduced pressure at 40°C to obtain a light brown crystalline powder, which was obtained after drying under reduced pressure at 45°C. 3,5-diacetoxyacetophenone 1.96Kg.

[0025] (2) Dissolve 3,5-diacetoxyacetophenone (1.02Kg, 5mol) in 5L of chloroform, add (800g, 5mol) bromine dropwise at 25°C, add in about 2 hou...

Embodiment 2

[0029] The preparation method of terbutaline sulfate, concrete steps comprise:

[0030] (1) Dissolve 3,5-dihydroxyacetophenone (1.52Kg, 10mol) in 10L of dichloromethane under nitrogen protection, add acetic anhydride (2.24Kg, 22mol), cool down to 20°C, and add trichloride in batches Aluminum (2.93kg, 22mol), the temperature is controlled between 20-25°C, the addition is completed in 2h, and the reaction is carried out at 20°C for 0.5h. After the reaction was completed, 10L of water was slowly added, stirred for 15min, allowed to stand for stratification, and the organic phase of the lower layer was washed with 10L of water once, and dichloromethane was evaporated under reduced pressure at 40°C to obtain a light brown crystalline powder, which was obtained after drying under reduced pressure at 45°C. 3,5-diacetoxyacetophenone 2.01Kg.

[0031](2) Dissolve 3,5-diacetoxyacetophenone (1.02Kg, 5mol) in 5L of chloroform, add (840g, 5.25mol) bromine dropwise at 25°C, add about 2.5h, ...

Embodiment 3

[0035] The preparation method of terbutaline sulfate, concrete steps comprise:

[0036] (1) Dissolve 3,5-dihydroxyacetophenone (1.52Kg, 10mol) in 10L of dichloromethane under nitrogen protection, add acetic anhydride (2.14Kg, 21mol), cool down to 15°C, and add trichloride in batches Aluminum (2.80kg, 21mol), the temperature is controlled between 15-20°C, the addition is completed in 2h, and the reaction is carried out at 20°C for 0.5h. After the reaction is completed, slowly add 10L of water, stir for 15min, let stand to separate layers, wash the lower organic phase with 10L of water once, evaporate dichloromethane to dryness under reduced pressure at 40°C to obtain a light brown crystalline powder, and dry under reduced pressure at 45°C to obtain 3,5-diacetoxyacetophenone 1.73Kg.

[0037] (2) Dissolve 3,5-diacetoxyacetophenone (1.02Kg, 5mol) in 5L of chloroform, add (821g, 5.13mol) bromine dropwise at 20°C, add about 2.5h, and add Then add 2.5L of 10% sodium carbonate solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com