Preparation method of sulfur-containing heavy calcium

A heavy calcium and sulfur technology, applied in the direction of superphosphate, phosphate fertilizer, fertilization devices, etc., can solve problems such as no relevant reports, and achieve the effect of low cost of technical transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

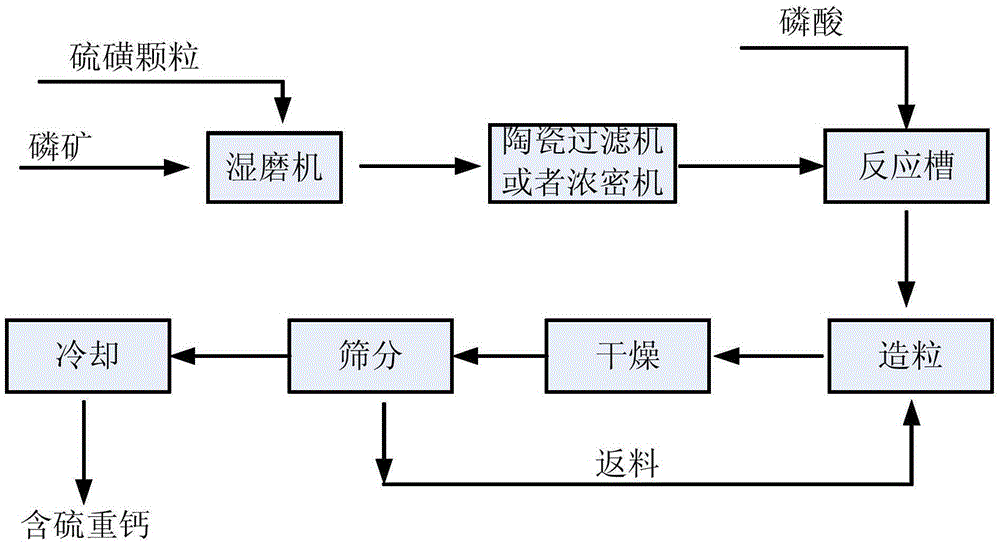

[0024] Production of heavy calcium sulfide, such as figure 1 Shown:

[0025] The first step: take sulfur particles according to the ratio of 7% of phosphate rock and add them to the wet mill through a belt and phosphate rock, mix with a certain amount of water for wet grinding to obtain a 200-mesh sieve with a liquid content of 30% sulfur-containing pulp, and then put The slurry is sent to a ceramic filter to remove part of the water to obtain a material with a liquid content of 8%.

[0026] The second step: production of heavy calcium sulfide. The above materials are figure 1 Introduce into a mixer, add phosphoric acid with a concentration of 46%, granulate after the reaction in the reaction tank is completed, dry with hot air below 250°C, crush and sieve to obtain sulfur-containing heavy calcium.

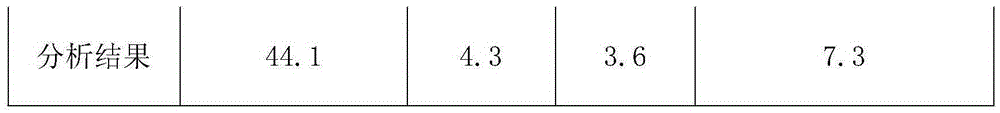

[0027] Table 1 Analysis results of sulfur and phosphate fertilizers

[0028] Indicator name

Embodiment 2

[0030] Step 1: Take sulfur particles with a particle size of ≤1cm, add them to the wet mill through a belt and the phosphate rock with a particle size of ≤1cm according to the proportion of 5% of the phosphate rock, add a certain amount of water to wet grind to get through a 200-mesh sieve, containing Sulfur-containing pulp with a liquid volume of 40%, and then the pulp is transported to a ceramic filter to remove excess water to obtain a material with a liquid content of 15%.

[0031] The second step: production of heavy calcium sulfide. The above materials are figure 1 Introduce into a mixer, add phosphoric acid with a concentration of 46%, granulate after the reaction in the reaction tank is completed, dry with hot air below 250°C, control the moisture content of the outlet material to ≤4.0%, and obtain sulfur-added heavy calcium after crushing and screening.

[0032] Table 2 Analysis results of sulfur-containing heavy calcium

[0033] Indicator name

Embodiment 3

[0035] Step 1: Take sulfur particles at a ratio of 3% and add them to the wet mill through a belt and phosphate rock, add a certain amount of water to wet mill to obtain a sulfur-containing pulp that has passed a 200-mesh sieve and has a liquid content of 50%, and then transport the pulp To the thickener, remove excess moisture to obtain a material with a liquid content of 20%.

[0036] The second step: production of heavy calcium sulfide. The above materials are figure 1 Introduce into a mixer, add phosphoric acid with a concentration of 46%, granulate after the reaction in the reaction tank is completed, dry with hot air below 250°C, crush and sieve to obtain heavy calcium sulfide.

[0037] Table 3 Analysis results of sulfur-containing heavy calcium

[0038]

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com