Groove-type cross-band veneer, and sheet material prepared from groove-type cross-band veneer

A grooved, core board technology, applied in the direction of layered products, chemical instruments and methods, wood-layered products, etc., can solve the problem that the end face of the grooved core board is easy to crack, rub off, and inconvenient for the alignment and splicing of the board. , inconvenient lap joint structure and other problems, to achieve the effect of releasing internal stress, facilitating protection, and facilitating evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

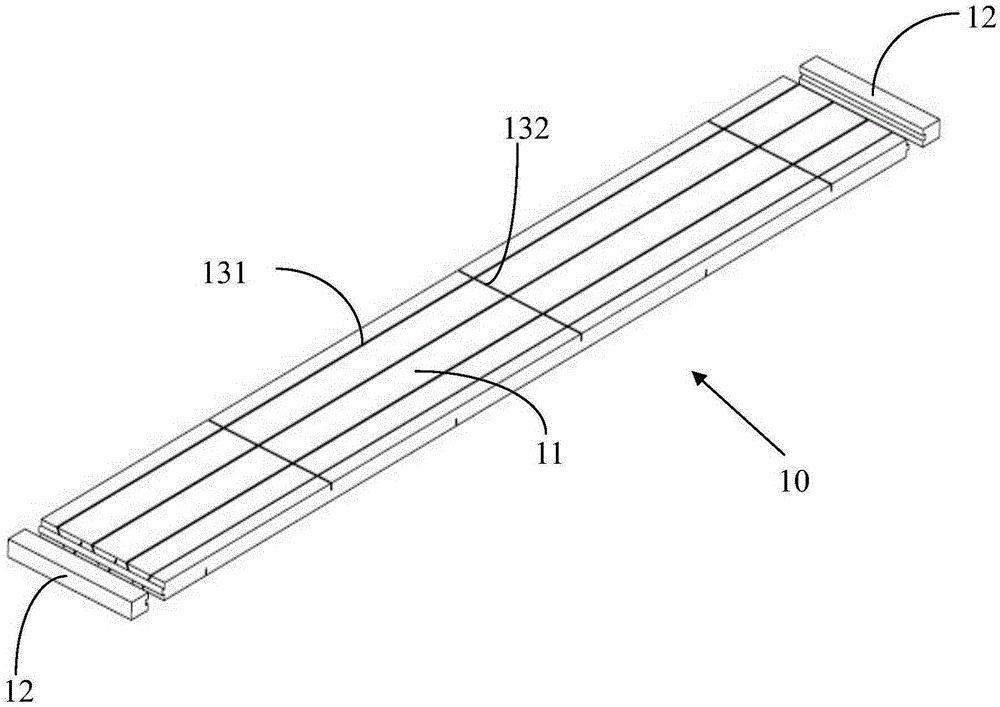

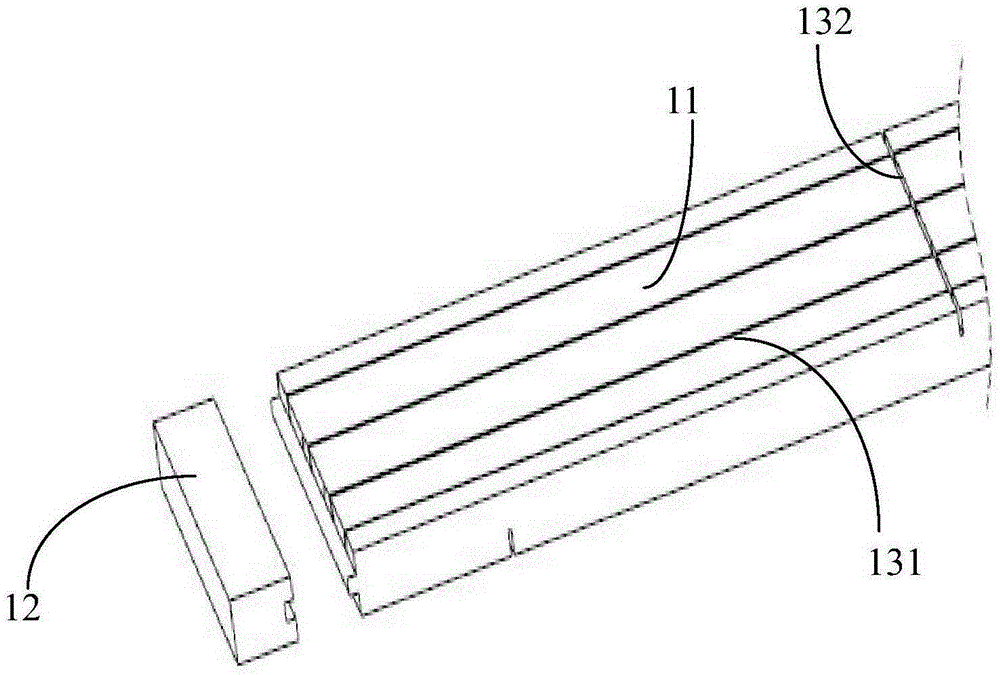

[0056] see figure 2 and image 3 As shown, the grooved core board 10 of the present invention is mainly composed of a core board body 11 and a connecting edge 12 arranged on the end surface of the core board body 11. The surface of the core board body 11 is provided with an angle range of 30°. °~90° groove, the connecting edge 12 is provided with a splicing structure for splicing with the adjacent grooved core board (the splicing structure is not shown in the figure). The grooves run through the corresponding end faces of the core board body 11. The core board body 11 is a strip-shaped board body, including a long side and a short side. The grooves include a main groove 131 arranged on the surface of the core board body 11 along the long side. The short sides are disposed on the sub-grooves 132 on the surface of the core board body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com