Autoclave die for forming parts with reinforcing ribs

A technology for reinforcing ribs and autoclave, which is applied in the field of autoclave molds, can solve the problems of difficulty in demoulding parts with reinforcing ribs, and achieves the effects of not easy to deform, accurate positioning, and accurate size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

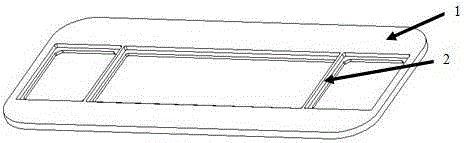

[0019] An autoclave mold for one-time molding of parts with reinforcing ribs, such as figure 2 , image 3 , including a mold body 3, a frame 4, and a boss group, the mold body 3 is provided with an annular groove 8 and a rectangular groove 9, the frame 4 is embedded in the annular groove 8, the frame 4 and the boss group are provided with 12 holes for release bolts, and the frame 4 and the boss group is also provided with fastening bolt 13 holes, the stripping bolt 12 holes are provided with a stripping bolt 12, the fastening bolt 13 holes are provided with a fastening bolt 13, and the boss group is embedded in the rectangular groove 9, The boss group includes more than two bosses, an upper stripping angle 10 is provided on the upper surface of each boss, and a lower stripping corner 11 is arranged on the lower surface of each boss. The boss group includes a left boss 7, a middle boss 6, and a right boss 5 arranged in sequence, and a gap is formed between any two of the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com