Hydraulic auxiliary charging system

A feeding system and hydraulic technology, applied in the direction of fluid pressure actuators, grain processing, servo motors, etc., can solve the problems of difficult feeding, reduce production efficiency, waste production costs, etc., and achieve the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be noted that the drawings are only illustrative and not drawn to a strict scale, and there may be local enlargement and reduction for the convenience of description, and there may be certain defaults for known parts of the structure; the following description uses The words "front", "rear", "left", "right", "upper" and "lower" refer to directions in the drawings, and the words "inner" and "outer" refer to The direction of the geometric center of the part.

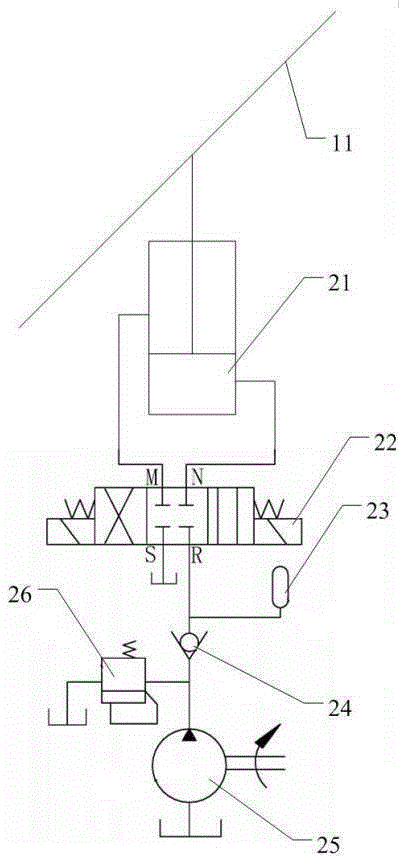

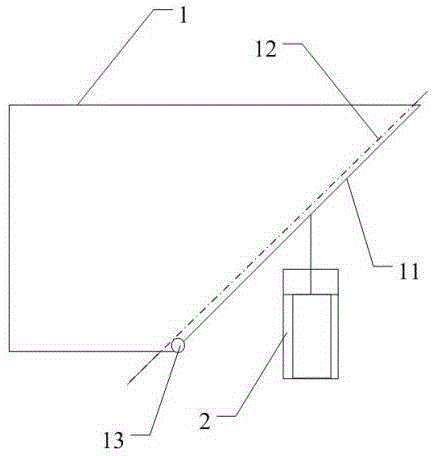

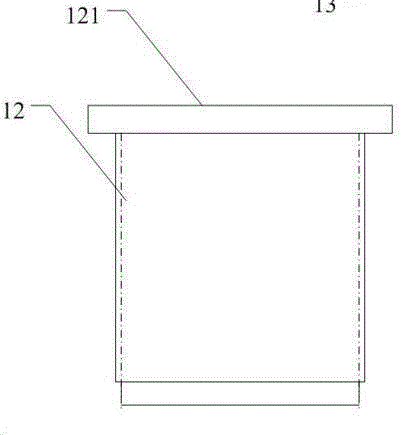

[0017] see figure 1 , 2 , 3. The present invention relates to a hydraulic auxiliary feeding system, including a feed port 1 and a hydraulic press 2. The feed port 1 includes a movable plate 11, and the movable plate 11 is movably connected to adjacent side plates through connecting pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com