Dry stuffing food forming method

A food molding and dry material technology, applied in food science, baking, dough processing, etc., can solve problems such as inability to form dough, damaged dough, leakage of stuffing, etc., and achieve the effect of small interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] This embodiment discloses a method for forming dry food, which is characterized in that it includes the following steps:

[0082] The first step is to place a single dough on the forming mold;

[0083] The second step is to pre-poke the dough with a skin-peeling mechanism to make the dough into a concave shape;

[0084] The third step is to use the filling mechanism to feed the dry material into the concave dough, and press the dough into the forming mold to form;

[0085] The fourth step is to use the stuffing mechanism to poke the stuffing, so that the dry ingredients are wrapped in the dough.

[0086] This embodiment adopts the mechanism involved in the horizontal arrangement of the discs.

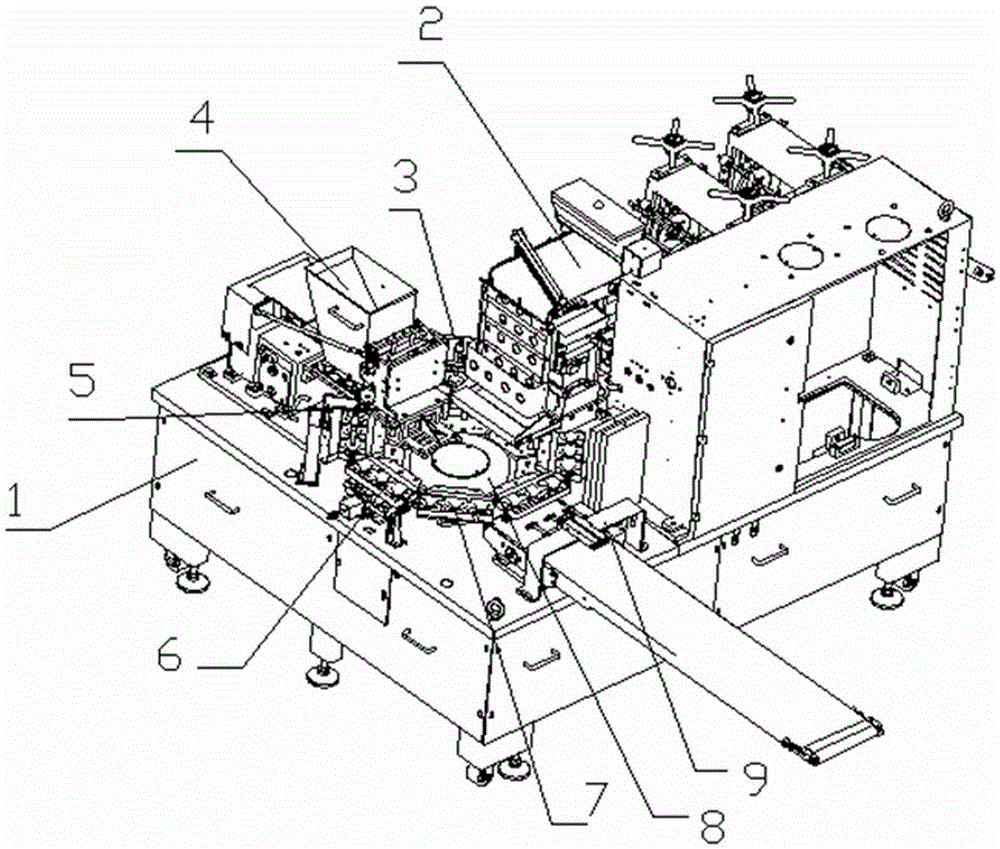

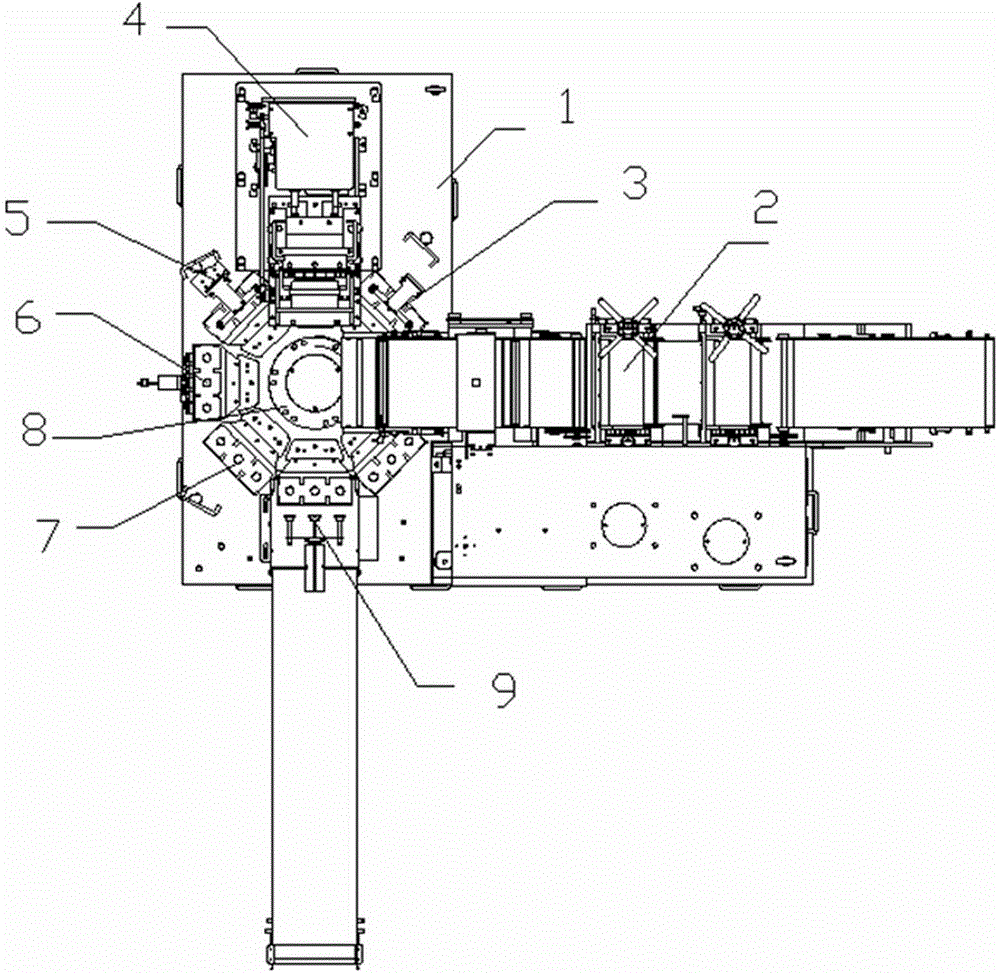

[0087] Present embodiment comprises frame 1, dough forming mechanism, skin mechanism 3, stuffing mechanism 4, stuffing mechanism 5, disc 8 and forming mold 7, and described disc 8 is fixed on the frame 1, and can Rotate on the frame 1, the forming mold 7 is fixed on the disc 8...

Embodiment 2

[0108] This embodiment adds a shaping step and a corresponding shaping mechanism on the basis of Example 1, specifically: a method for forming dry food, which is characterized in that it includes the following steps:

[0109] The first step is to place a single dough on the forming mold;

[0110] The second step is to pre-poke the dough with a skin-peeling mechanism to make the dough into a concave shape;

[0111] The third step is to use the filling mechanism to feed the dry filling into the concave dough, and press the dough into the forming mold to form;

[0112] The fourth step is to poke the stuffing with a stuffing mechanism so that the stuffing is wrapped in the dough.

[0113] After the fourth step is completed, the packaged dry food is shaped by a shaping mechanism, and the shaped dry food is kneaded again.

[0114] The effect of shaping mechanism 6 is to carry out shaping to the manufactured product, manufacture the product with beautiful appearance, also play a kn...

Embodiment 3

[0117] This embodiment is based on Embodiment 1 or 2, adding a pushing step and a corresponding pushing mechanism, specifically: .

[0118] A method for forming dry food, characterized in that: comprising the following steps:

[0119] The first step is to place a single dough on the forming mold;

[0120] The second step is to pre-poke the dough with a skin-peeling mechanism to make the dough into a concave shape;

[0121] The third step is to use the filling mechanism to feed the dry filling into the concave dough, and press the dough into the forming mold to form;

[0122] The fourth step is to poke the stuffing with a stuffing mechanism so that the stuffing is wrapped in the dough.

[0123] After the fourth step is completed, the packaged dry food is shaped by a shaping mechanism, and the shaped dry food is kneaded again.

[0124] After the dry food is shaped, the pushing mechanism is used to push the shaped dry food onto the conveyor belt.

[0125] The function of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com