Inkpad holder for self-inking stamp and device and method for producing the same

A technology for holders and printing pads, which is applied to the equipment for injection molding such printing pad holders, and the field of manufacturing such printing pad holders. It can solve the problems of polluting the insertion chamber, contamination of the seal, and dirt from the user, and achieves a fixed and reinforced effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

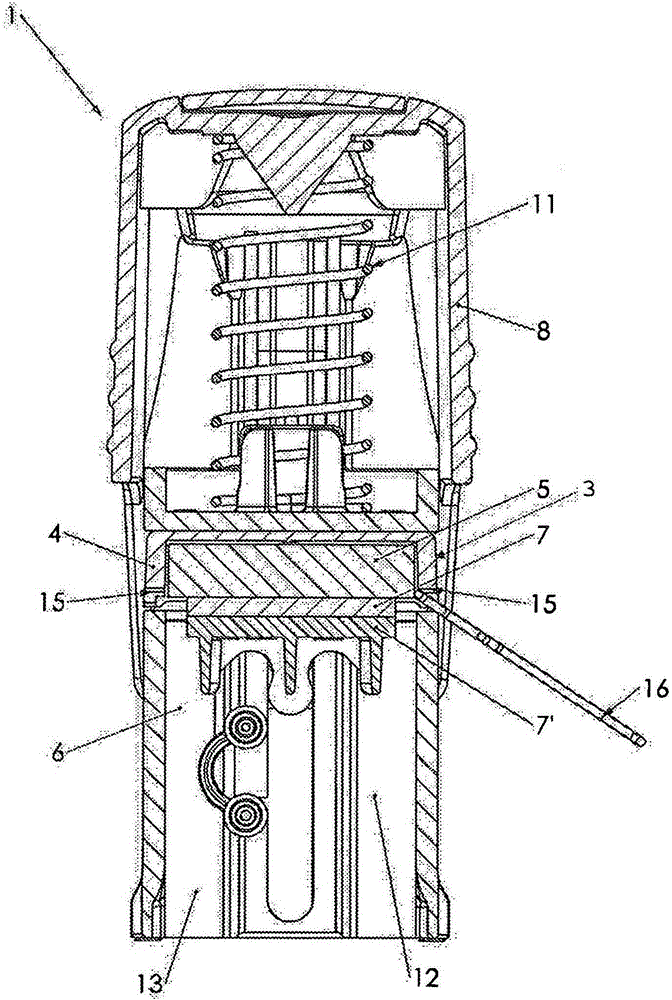

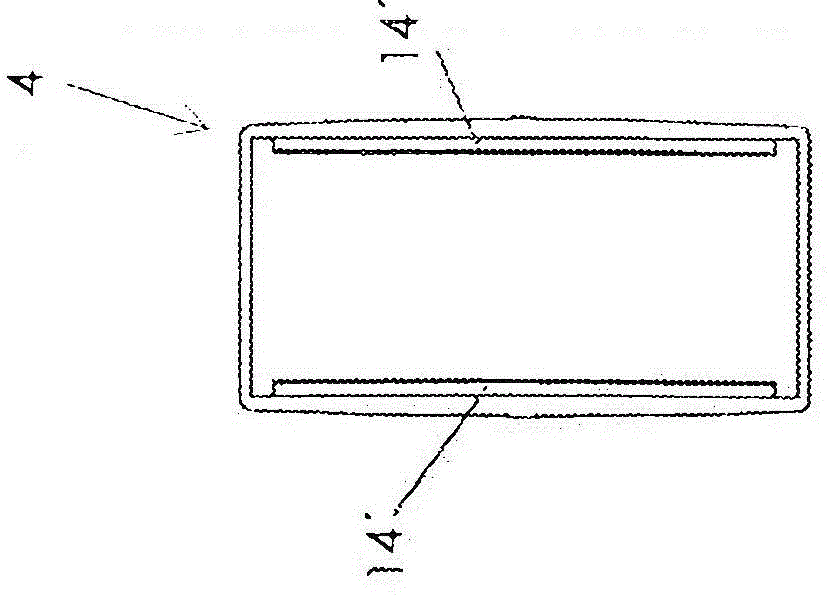

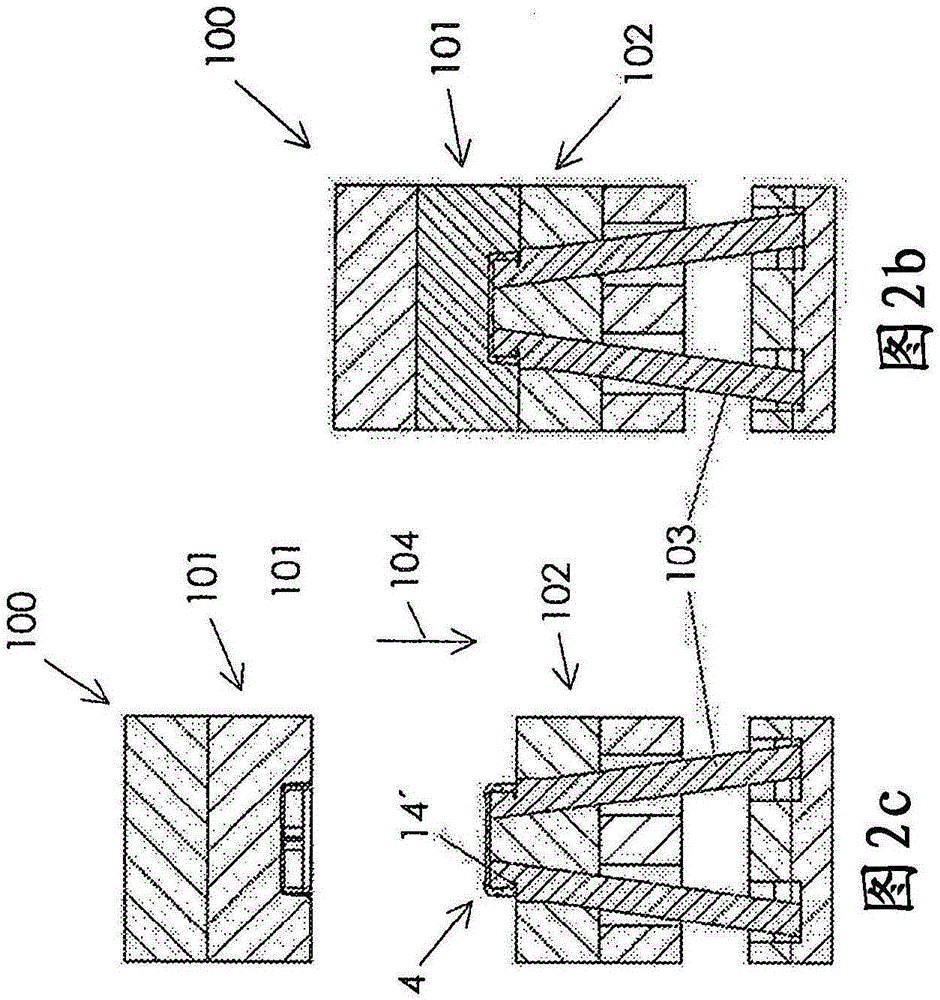

[0043] exist figure 1 1 shows a conventional ink-returning stamp 1, which has a frame-like stamp housing 2 (hereinafter referred to as housing 2). The housing 2 has an insertion chamber 3 for a stamping pad holder 4 arranged exchangeably therein, in which a stamping pad 5 is accommodated. To replace the pad holder 4, according to figure 1 A paper clip 16 is used, with which it engages in the recess 15 of the stamp holder 4 . Alternatively, the insertion chamber can be open towards both sides, so that the pad holder 4 without the recess 15 can be pressed out of the insertion chamber 3 . A stamping unit 6 is also provided inside the housing 2, and the stamping unit includes a printing plate 7 with stamped characters mounted on a printing plate support 7'. Stamping unit 6 in figure 1 is shown in the inking position against the printing pad 5 .

[0044] For actuating the ink return stamp 1 , an actuating bow 8 is provided, which in the exemplary embodiment shown is fitted ont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com