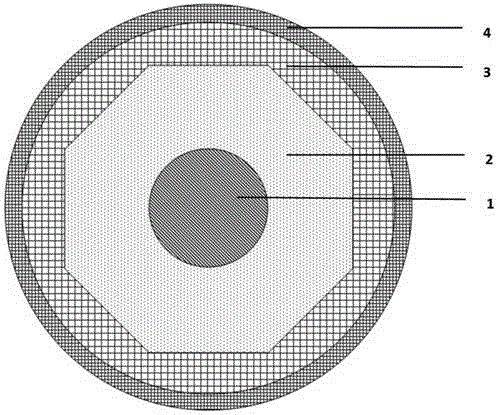

Large-mode-field ytterbium-doped optical fiber

A ytterbium-doped fiber, large mode field technology, applied in the direction of cladding fiber, multi-layer core/cladding fiber, optical waveguide light guide, etc. bad etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

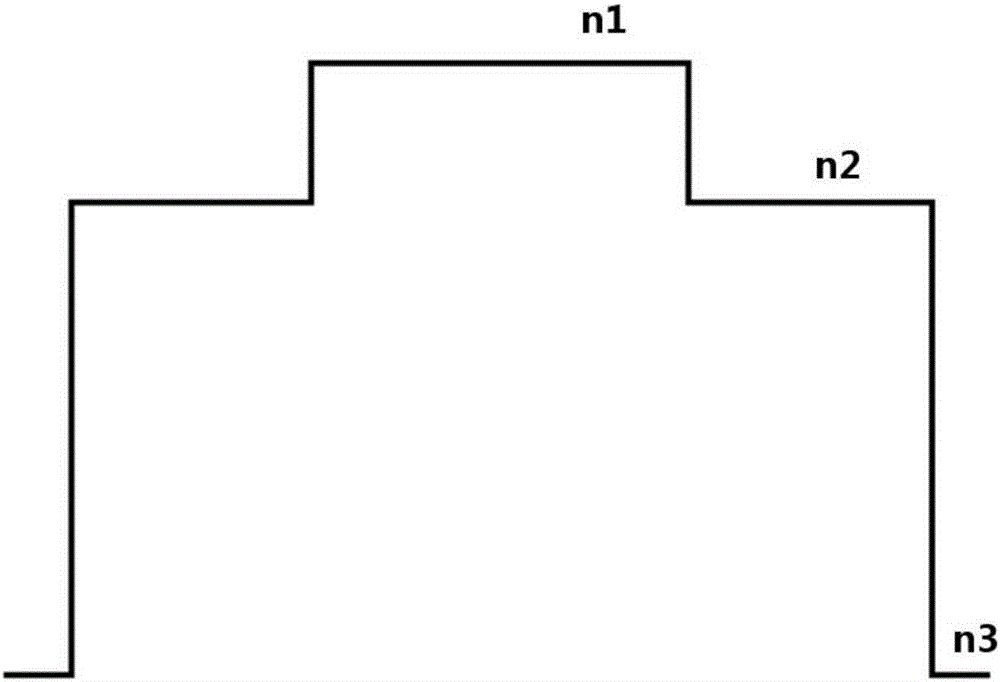

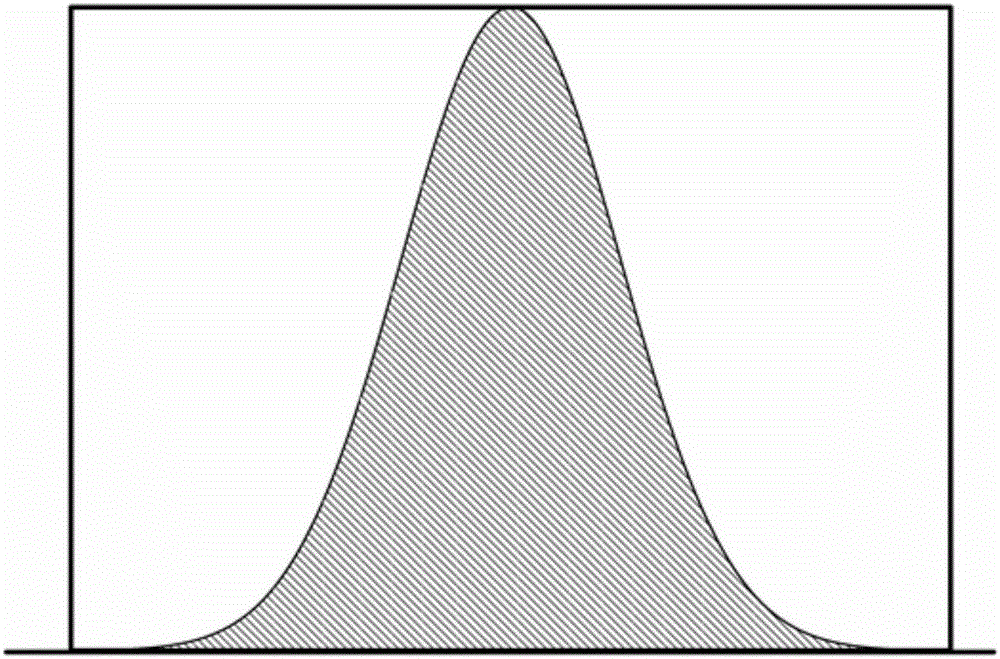

[0035] Example 1. During the test, the diameter of the fiber coil was kept fixed at 30cm: the core diameter was 20μm, the cladding diameter was 400μm, β=1, and the doping concentration of ytterbium in the core was nearly Gaussian. 2 o 3 The highest concentration calculated by mass fraction is 1000ppm, NA is 0.08, and the test results are processed by signal M 2 =1.2, the mode field diameter is 15um, the output power is 130W, and the slope efficiency is 70%. Test conditions: the output power of two 915nm LD pumps is 100W, and the central wavelength of the grating is 1060nm.

Embodiment 2

[0037] Example 2. During the test, the fiber coil diameter was kept fixed at 30cm: the core diameter was 30μm, the cladding diameter was 400μm, β=0.9, and the doping concentration of ytterbium in the core was Gaussian. 2 o 3 The highest concentration that mass fraction calculates is 1000ppm, and NA is 0.06, and other test conditions are identical with embodiment 1, and test result is through signal processing M 2 =1.3, the mode field diameter is 23um, the output power is 132W, and the slope efficiency is 71%.

Embodiment 3

[0039] Example 3. During the test, the diameter of the fiber coil was kept fixed at 30cm: the core diameter was 35μm, the cladding diameter was 400μm, β=1.1, and the doping concentration of ytterbium in the core was Gaussian. 2 o 3 The highest concentration that mass fraction calculates is 1000ppm, and NA is 0.06, and other test conditions are identical with embodiment 1, and test result is through signal processing M 2 =1.5, the mode field diameter is 29um, the output power is 134W, and the slope efficiency is 72%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com