A liquid cooling apparatus based on an oil immersed transformer heat dissipation device

An oil-immersed transformer and radiator technology, applied in the direction of transformer/inductor cooling, etc., can solve the problems of small water specific heat capacity, water leakage or air leakage, increase safety hazards, etc., achieve large thermal conductivity, increase service life, and ensure work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

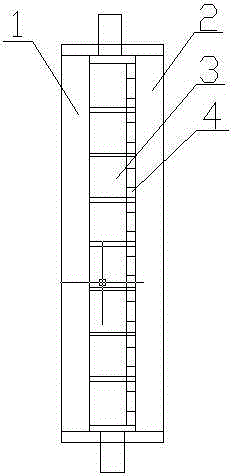

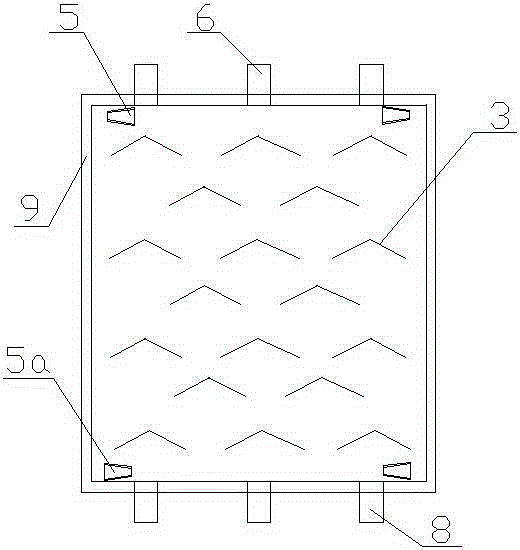

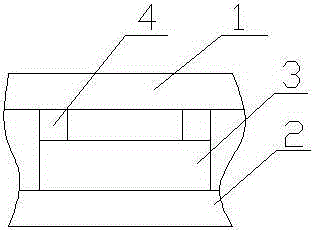

[0041] Embodiment 1: A liquid cooling device based on an oil-immersed transformer radiator, including a transformer surrounding wall 1 whose back is connected to the back plate 2 through several connecting pieces, and the connecting pieces pass through the back of the transformer surrounding wall 1 or The deflector 3 provided on the front of the back plate 2 is connected to the back plate 2 or the transformer surrounding wall 1, and the connection between the back plate 2 and the transformer surrounding wall 1 is formed by the connecting piece Coolant clearance.

[0042]A sealing plate 9 is arranged around the coolant gap, and a water inlet 6 and a water outlet 8 are respectively arranged at two parallel sealing plates 9 .

[0043] The deflector 3 is arranged at the water inlet 6 , and the top surface of the deflector 3 is not parallel to the water flow direction of the water inlet 6 .

[0044] The top view of the baffles 3 is in an inverted V shape, and the baffles are arran...

Embodiment 2

[0051] Embodiment 2: A liquid cooling device based on an oil-immersed transformer radiator, including a transformer surrounding wall 1 whose back is connected to the back plate 2 through several connecting pieces, and the connecting pieces pass through the back of the transformer surrounding wall 1 or The deflector 3 provided on the front of the back plate 2 is connected to the back plate 2 or the transformer surrounding wall 1, and the connection between the back plate 2 and the transformer surrounding wall 1 is formed by the connecting piece Coolant clearance.

[0052] A sealing plate 9 is arranged around the coolant gap, and a water inlet 6 and a water outlet 8 are respectively arranged at two parallel sealing plates 9 .

[0053] The deflector 3 is arranged at the water inlet 6 , and the top surface of the deflector 3 is not parallel to the water flow direction of the water inlet 6 .

[0054] The top view of the baffles 3 is in an inverted V shape, and the baffles are arra...

Embodiment 3

[0061] Embodiment three, its difference with embodiment one or two is:

[0062] Embodiment 2: A liquid cooling device based on an oil-immersed transformer radiator, including a transformer surrounding wall 1 whose back is connected to the back plate 2 through several connecting pieces, and the connecting pieces pass through the back of the transformer surrounding wall 1 or The deflector 3 provided on the front of the back plate 2 is connected to the back plate 2 or the transformer surrounding wall 1, and the connection between the back plate 2 and the transformer surrounding wall 1 is formed by the connecting piece Coolant clearance.

[0063] A sealing plate 9 is arranged around the coolant gap, and a water inlet 6 and a water outlet 8 are respectively arranged at two parallel sealing plates 9 .

[0064] The deflector 3 is arranged at the water inlet 6 , and the top surface of the deflector 3 is not parallel to the water flow direction of the water inlet 6 .

[0065] The top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com