Numerical control machining feature customizing method

A processing feature, custom technology, applied in the direction of program control, computer control, general control system, etc., can solve problems such as limited application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

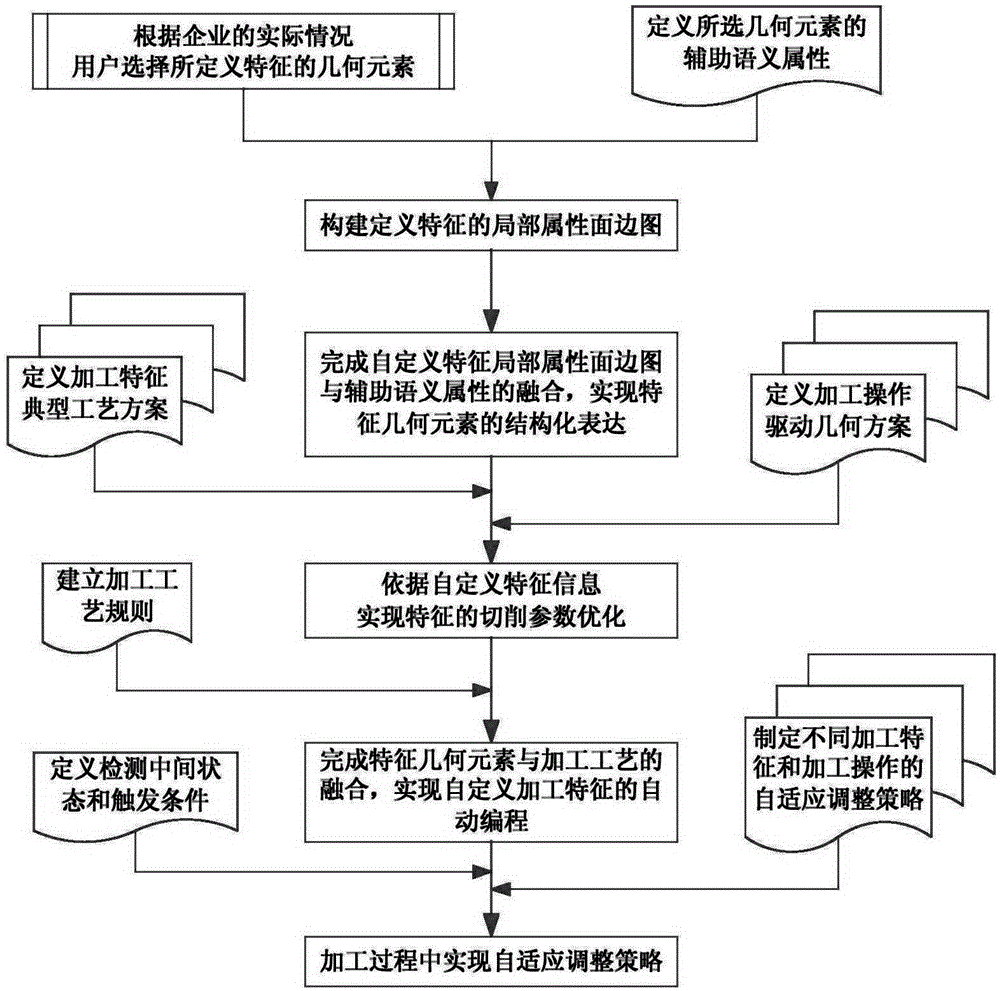

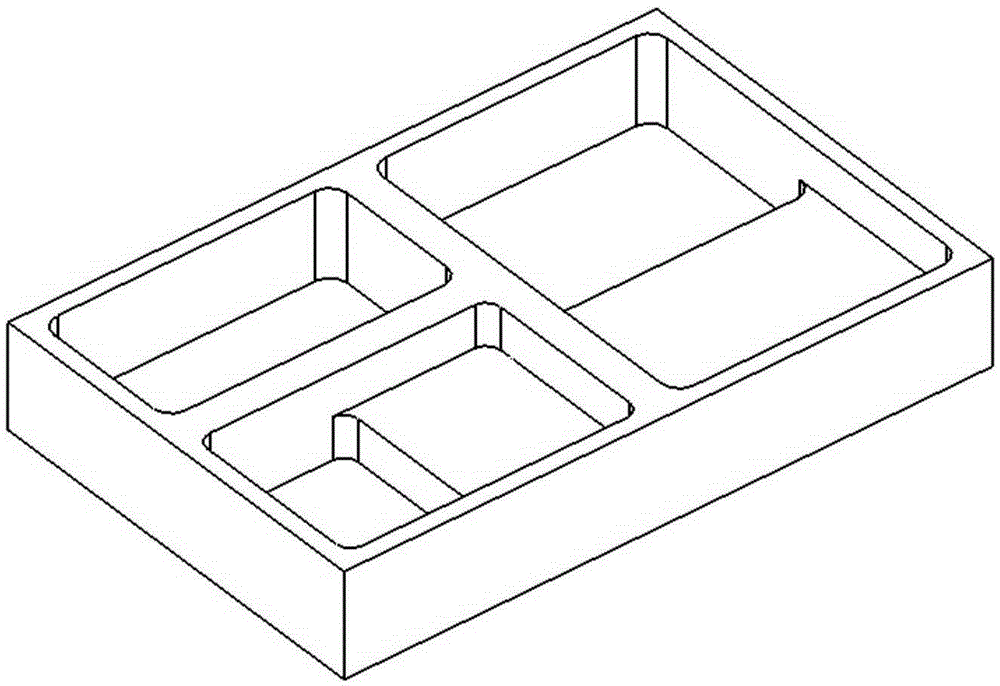

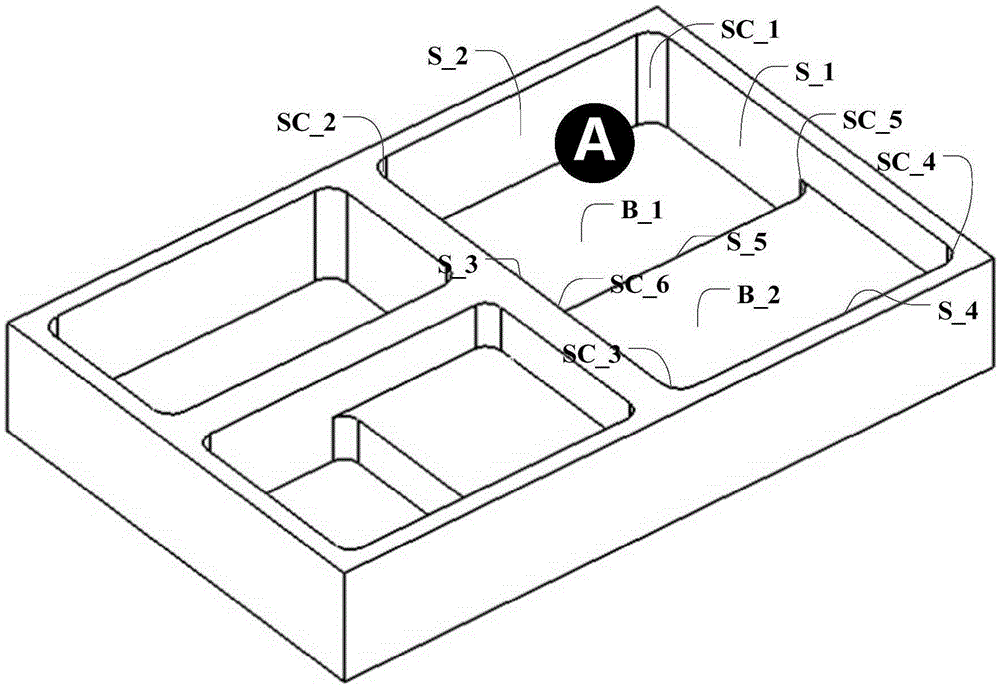

[0023] Such as Figure 1-5 shown.

[0024] A method for custom processing features of numerical control processing, the process of which is as follows figure 1 As shown, based on the 3D CAD model of the part, the user first customizes the geometric shape of the processing features according to the manufacturing resources, part structure and programming habits of the enterprise, and then clicks the geometric elements of the 3D model of the part through the interactive interface to automatically record all Select the topological relationship between geometric elements and the properties of faces and edges, and the user defines the key geometric parameter information and calculation method of the processing feature, and assigns a unique identifier to each custom processing feature, and the user interactively inputs the information of the processing featur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com