Reservoir flow velocity measurement method based on pressure sensor

A pressure sensor and flow velocity measurement technology, applied in the application field, can solve the problems of limited applicable occasions, inflexible use, interference with fluid form, etc., to achieve the effect of improving measurement accuracy, saving labor costs, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

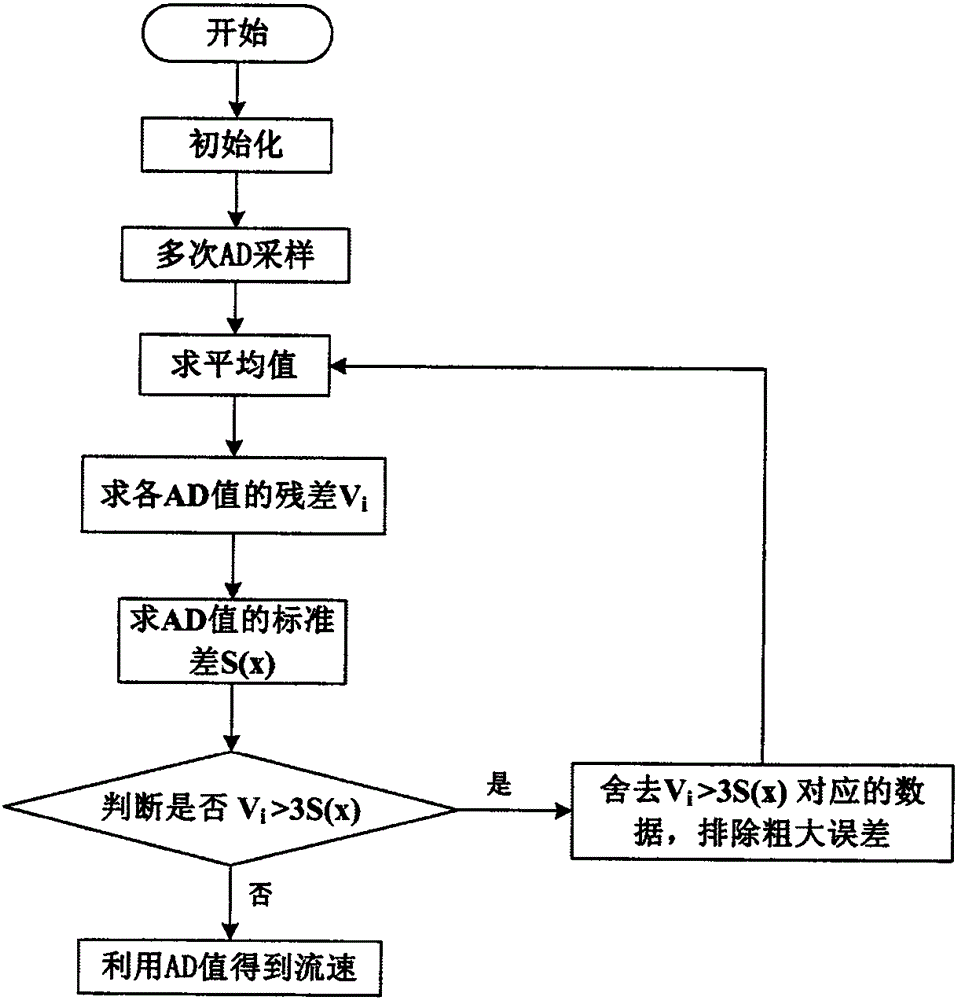

[0014] In order to describe in detail the system structure, module connections, working conditions and purpose of the data processing algorithm of the present invention, a detailed description will be given below in conjunction with specific examples and accompanying drawings.

[0015] Example one

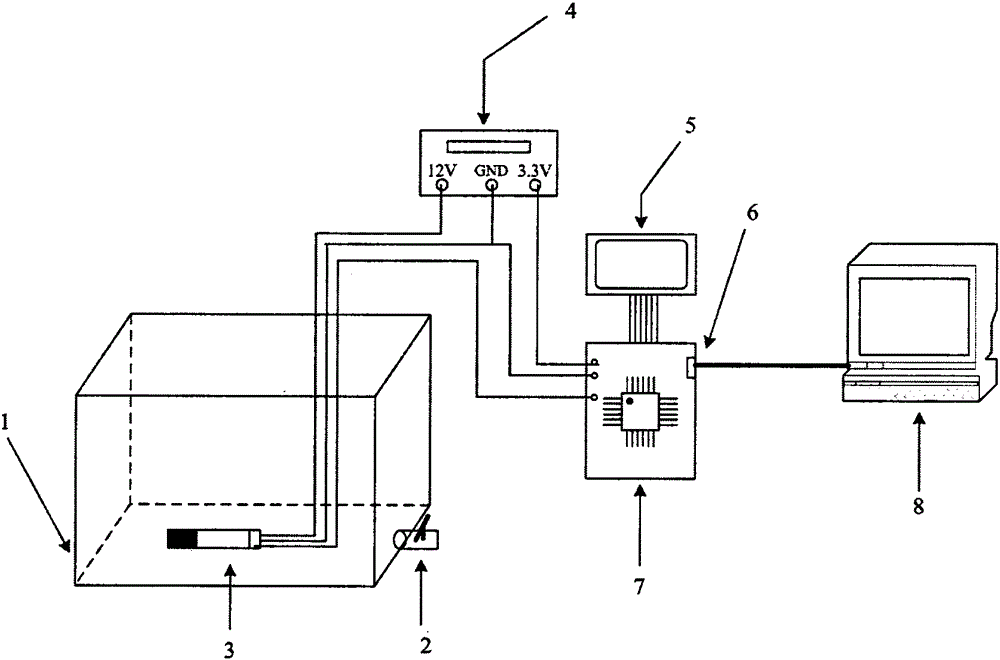

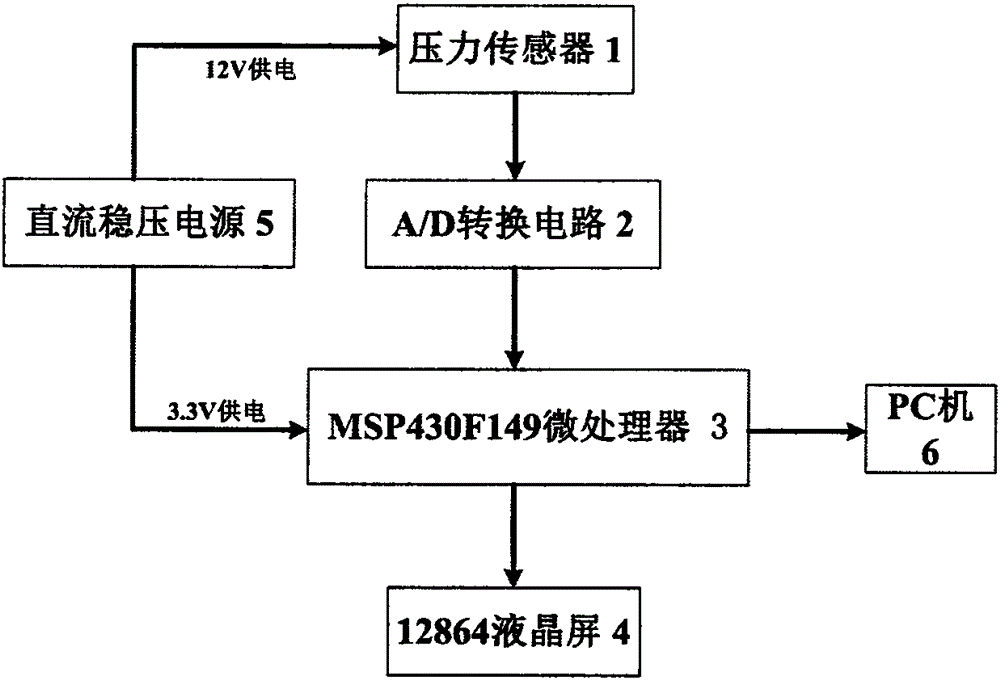

[0016] refer to figure 1 , the system structure of the present invention is described in detail below:

[0017] A method for measuring the flow rate of a water storage tank based on a pressure sensor. Its system structure includes a water tank 1, a faucet 2, a pressure sensor 3, a DC stabilized power supply 4, a 12864 LCD screen 5, a serial port 6, an MSP430F149 microprocessor 7, and a PC Machine 8.

[0018] The water tap 2 is fixed on the bottom of the water tank 1 and is responsible for controlling the opening and closing of the water flow. The pressure sensor 3 is placed at the bottom of the water tank. Since it is placed in the water, it is necessary to take corresponding wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com