The exterior wall structure of a new type portal frame steel structure building and the installation method of purlins on the wall

A technology for portal frames and building exterior walls, applied in building components, building structures, buildings, etc., can solve the problems of unusable I-beam space, poor connection structure stress, and poor overall stability, so as to save purlins The effect of length, increasing building span, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

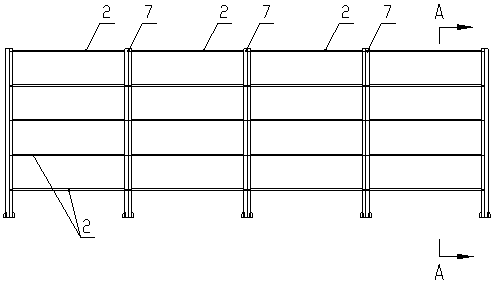

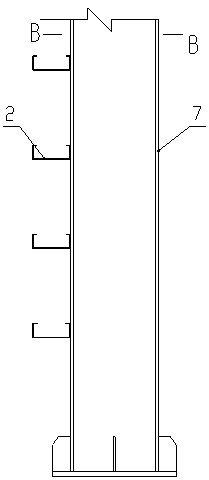

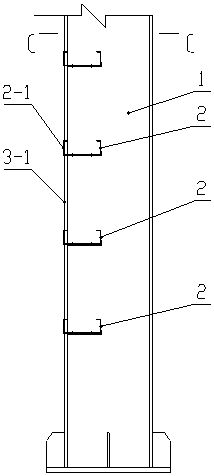

[0031] Such as figure 1 , 3 , 5, the present invention includes some wall purlins 2 and several vertically arranged steel columns 7, the steel columns 7 adopt I-beam 1, and the I-beam in the present embodiment is H-beam, I-beam 1 It includes a web 5 , an outer flange 3 and an inner flange 4 connected to both ends of the web 5 , and the outer flange 3 and the inner flange 4 are parallel. Wall purlins 2 are used as purlins. Several wall purlins 2 are connected at intervals from top to bottom between two I-beams 1 , and the wall purlins 2 are parallel to each other. In this embodiment, the wall purlin 2 adopts C-shaped steel.

[0032] Both sides of the web 5 near the outer flange plate 3 on the I-beam are connected with wall purlins 6, the wall purlin 2 is perpendicular to the web 5 of the I-beam 1, and the two ends of the wall purlin 2 are respectively connected On the two wall purlin brackets 6 corresponding to the adjacent I-beam, the outer side 2-1 of the wall purlin 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com