A frame beam-column joint reinforcement structure and its construction method

A technology of beam-column joints and reinforced structures, which is applied to building components, building structures, building maintenance, etc., can solve problems such as joint stiffness difficult to meet design requirements, construction difficulties, etc., achieve good economic benefits, small welding workload, meet The effect of design requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

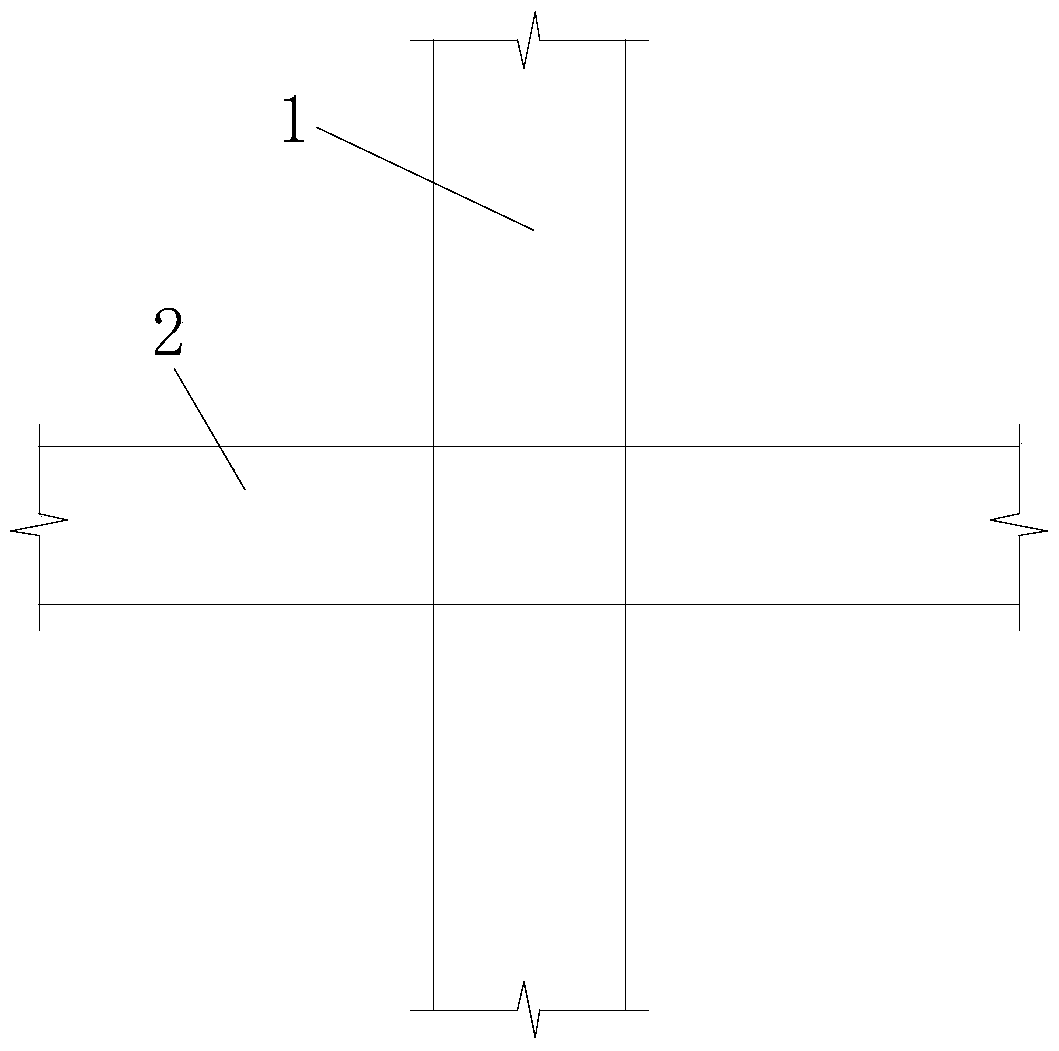

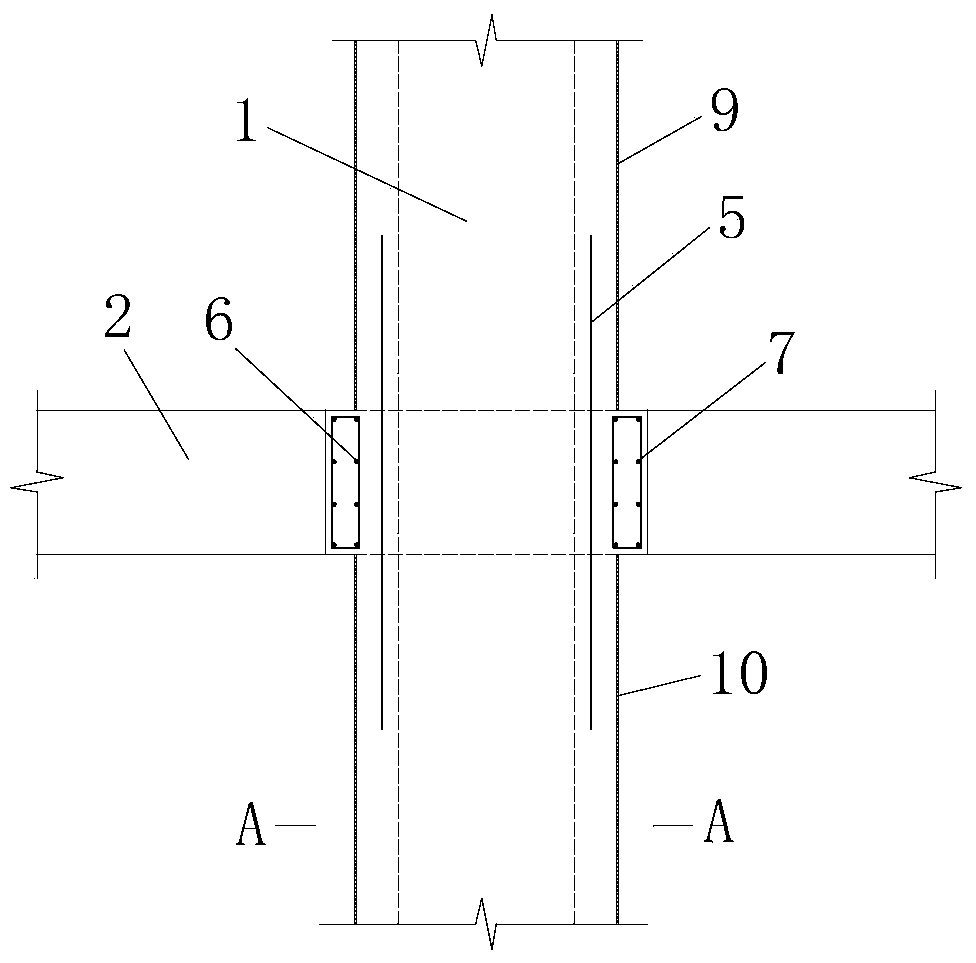

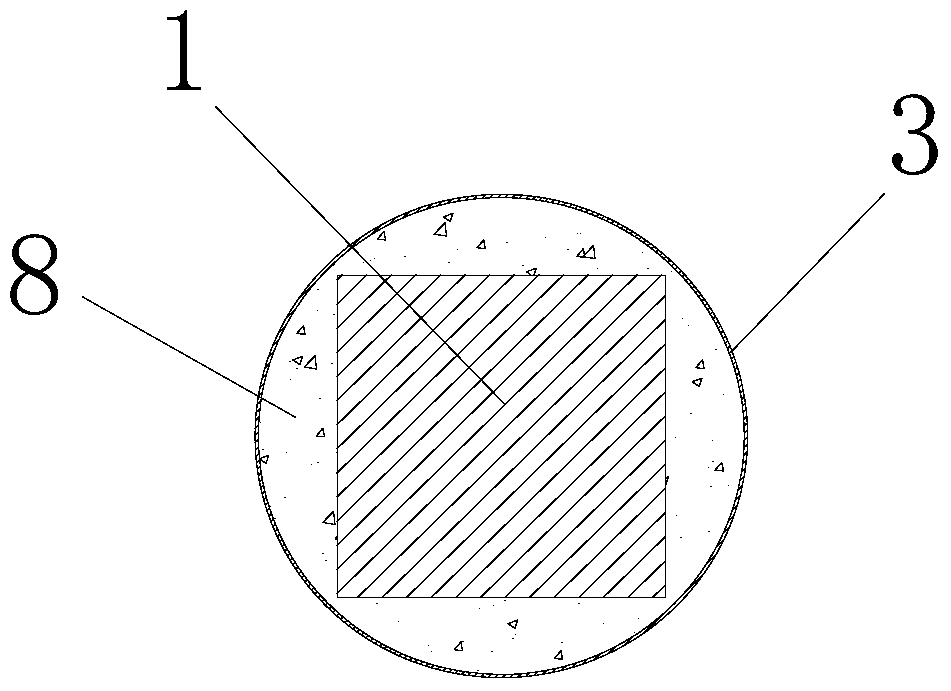

[0033] A reinforcement structure for frame beam-column joints, comprising original frame columns 1, frame beams 2, steel sleeves 3, and reinforcement cages 4, the reinforcement cages including inserting reinforcement 5, inner ring beam ring reinforcement 6 and outer ring beam ring Rib 7, the frame beam is connected to the original frame column, the ring reinforcement of the inner ring beam and the ring reinforcement of the outer ring beam respectively pass through the frame beam and surround the outside of the original frame beam-column joint, and the ring reinforcement of the outer ring beam is located on the ring beam of the inner ring On the outer side of the ring reinforcement, the insertion reinforcement is arranged vertically and connected with the inner ring beam ring reinforcement. The steel casing surrounds the original frame column, and also includes filling between the steel casing and the original frame column and filling the reinforcement cage The reinforced concre...

Embodiment 2

[0044] A construction method for strengthening the frame beam-column joints. Holes are opened on the floor slab at the edge of the original frame column, and holes are opened on the side of the frame beam for the ring ribs of the inner ring beam and the ring ribs of the outer ring beam to pass through. The beam ring reinforcement and the outer ring beam ring reinforcement respectively surround the beam-column joints of the original frame, the inserting reinforcement is set vertically and connected with the inner ring beam ring reinforcement, and the inner ring beam ring reinforcement and the outer ring beam ring reinforcement are bound A reinforcement cage is formed in the ring beam stirrup, the steel casing is surrounded by the original frame column, and concrete is poured between the steel casing and the original frame column and on the reinforcement cage to form a reinforced concrete layer.

[0045] Preferably, before concrete is poured on the reinforcement cage, formwork is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com