One-component polyurethane waterproof coating for facade spraying and preparation method thereof

A polyurethane waterproof, one-component technology, applied in the field of coatings, to achieve uniform film formation, reduce construction labor costs, and enhance the strength of the coating film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

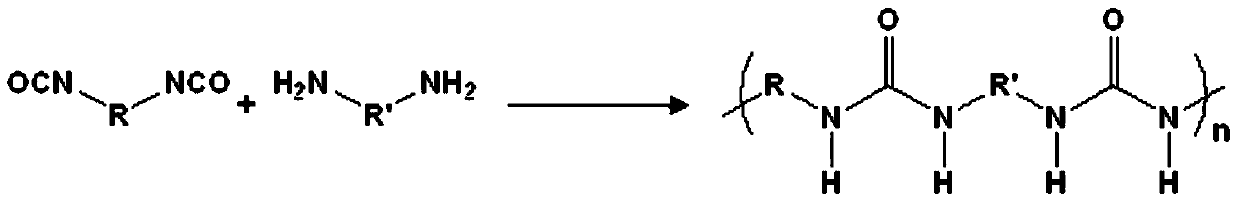

Method used

Image

Examples

Embodiment 1

[0036] A kind of facade spraying one-component polyurethane waterproof coating, by weight, is composed as follows:

[0037] components

parts by weight

Polyether diol DL-2000D

22

Polyether Triol 330N

6

Diisocyanate TDI-80

1.5

[0038] Diisocyanate MDI-50

2

Diisocyanate MDI-100

4

Chlorinated paraffin

20

3

1250 mesh talcum powder

17

800 mesh talcum powder

20

Titanium dioxide

2

0.05

Dimethylthiotoluenediamine

0.3

reactive thixotropic agent

0.5

Organotin Catalyst T-12 (Dibutyltin Dilaurate)

0.1

Defoamer BYK-066N

0.1

trimethylbenzene

5

5

[0039] The preparation method is:

[0040] (1) Add polyether polyols, plasticizers, pigments and fillers, and chain extenders into the reaction vessel, disperse evenly at high speed, stir and heat up to ...

Embodiment 2

[0046] A kind of facade spraying one-component polyurethane waterproof coating, by weight, is composed as follows:

[0047] components

parts by weight

Polyether diol DL-2000D

22

Polyether Triol 330N

6

Diisocyanate TDI-80

1.5

Diisocyanate MDI-50

2

Diisocyanate MDI-100

4

Chlorinated paraffin

20

3

1250 mesh talcum powder

17

800 mesh talcum powder

20

Titanium dioxide

2

[0048] carbon black

0.05

4,4'-Diamino-3,3'-dichlorodiphenylmethane

0.3

reactive thixotropic agent

0.5

Organotin Catalyst T-12 (Dibutyltin Dilaurate)

0.1

Defoamer BYK-066N

0.1

trimethylbenzene

4

5

[0049] The preparation method is:

[0050] (1) Add polyether polyols, plasticizers, pigments and fillers, and chain extenders into the reaction vessel, disperse evenly at high speed, stir an...

Embodiment 3

[0056] A kind of facade spraying one-component polyurethane waterproof coating, by weight, is composed as follows:

[0057] components

parts by weight

Polyether diol DL-2000D

20

Polyether Triol 330N

6

Diisocyanate MDI-50

3

Diisocyanate MDI

4

Chlorinated paraffin

17

3

800 mesh talcum powder

20

1250 mesh talcum powder

17

Titanium dioxide

2

0.05

Dimethylthiotoluenediamine

0.2

reactive thixotropic agent

0.7

0.2

Defoamer BYK-066N

0.3

Propylene glycol methyl ether acetate

5

6

[0058] The preparation method is:

[0059] (1) Add polyether polyols, plasticizers, pigments and fillers, and chain extenders into the reaction vessel, disperse evenly at high speed, stir and heat up to 100°C, and dehydrate for 2 hours under the condition of vacuum degree...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com