Electric pallet type carrying vehicle

A technology of pallet type and truck, applied in the direction of lifting device, etc., can solve the problems of single function and uncompact structure, and achieve the effect of compact space of the whole vehicle, simple and convenient maintenance, and increased descending speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

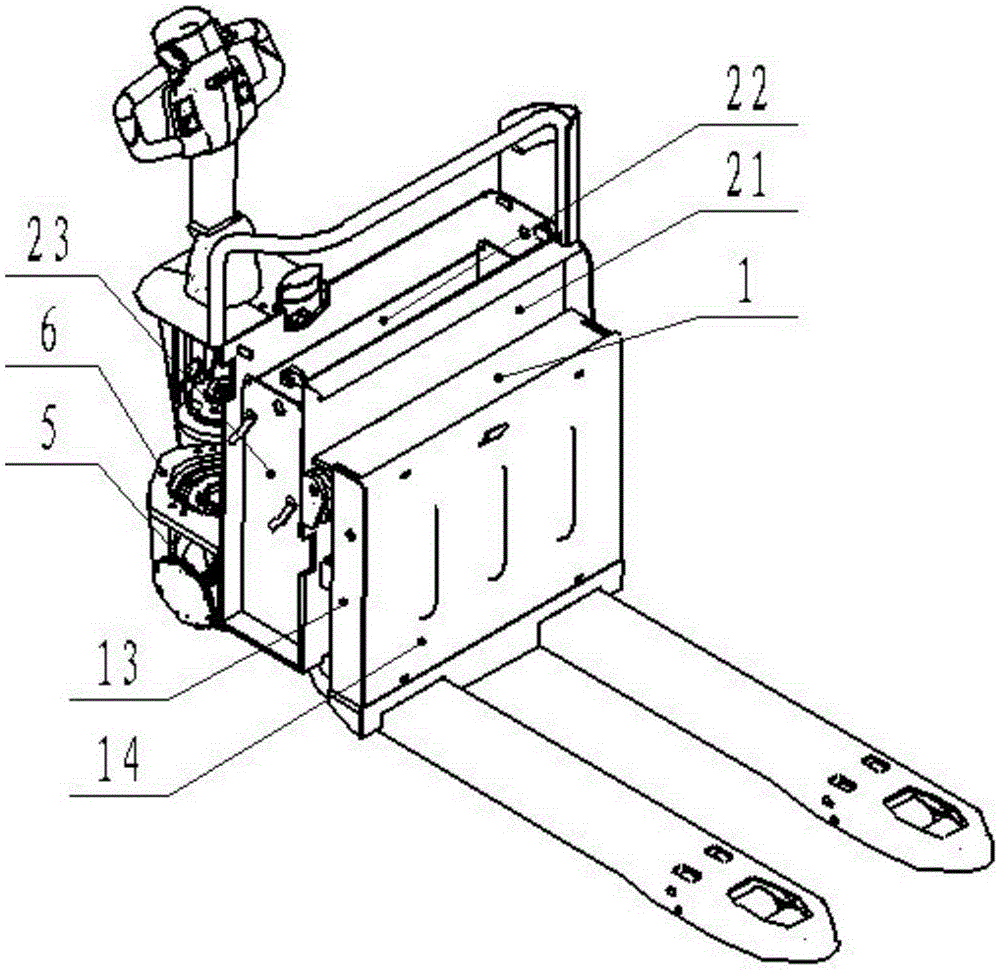

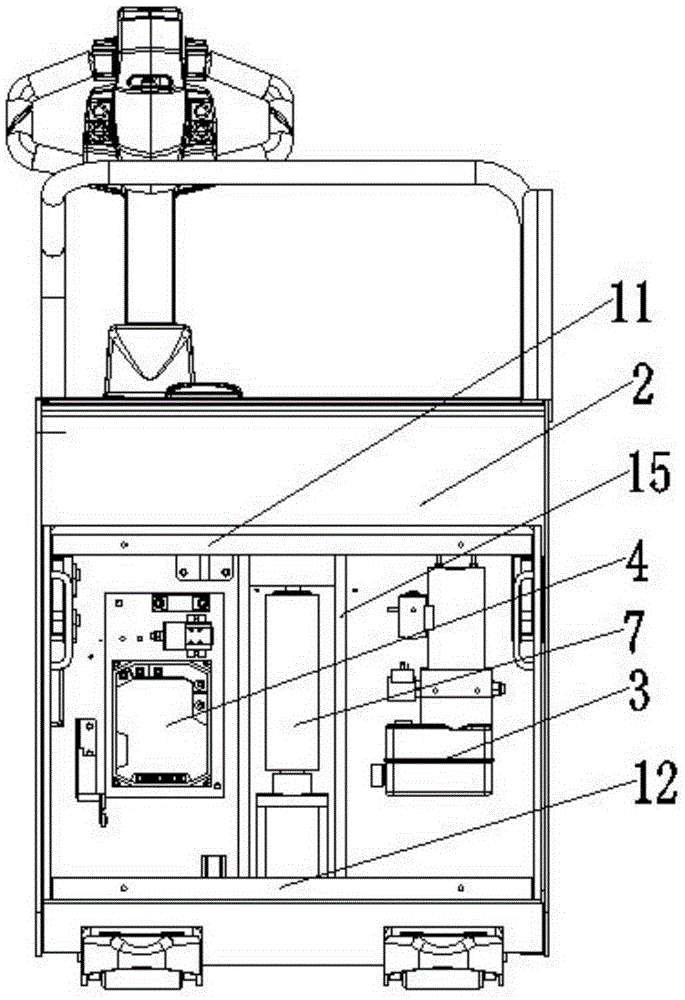

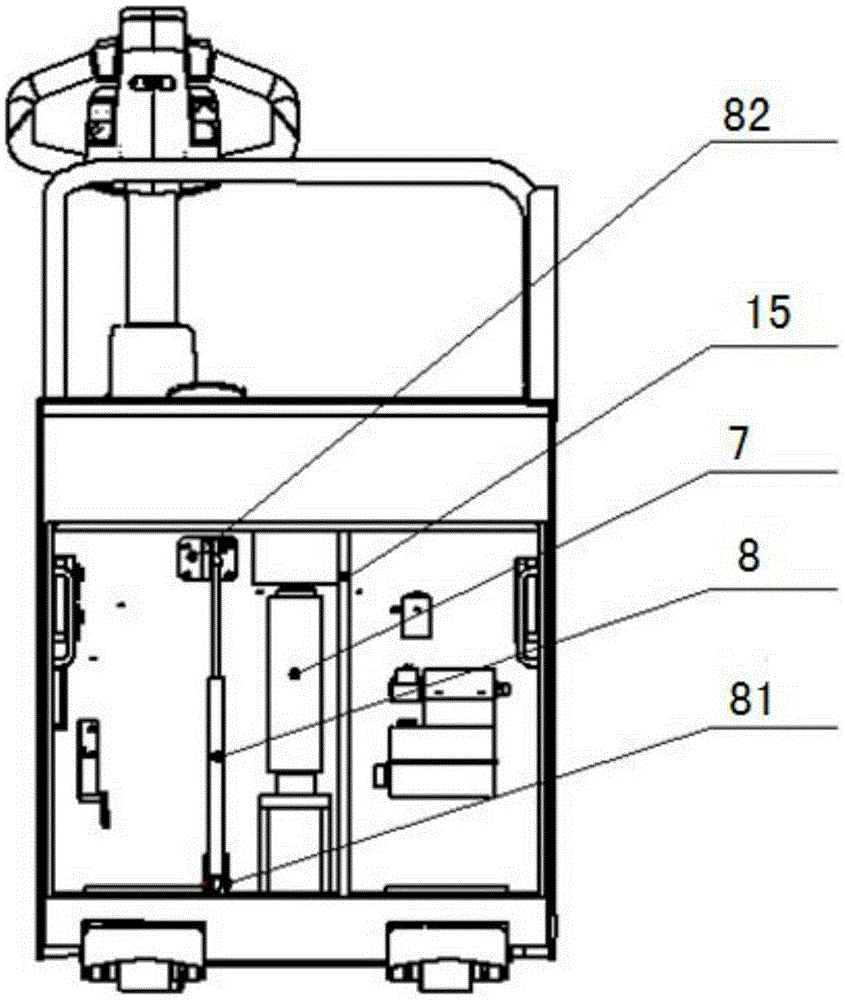

[0036] Electric pallet trucks such as figure 1 , figure 2 As shown, it includes a front frame 1 and a rear frame 2. The rear frame 2 includes a front end plate 21, a rear end plate 22 and two side plates 23, and the two side plates 23, the front end plate 21 and the rear end plate 22 are jointly constructed. A battery box is formed, and a battery is arranged in the battery box. The battery is placed in the rear frame 2 and does not move up and down with the front frame 1. The cable harnesses in the vehicle are fixed on the frame and cannot move, so that the cables and wire harnesses have a longer life.

[0037] The front frame 1 is a frame structure comprising an upper end plate 11, a lower end plate 12 and two side end plates 13, and a beam 15 is also provided between the upper end plate 11 and the lower end plate 12 to ensure the structural strength of the front frame 1. On the vehicle frame 1, a panel 14 is arranged on the end face away from the rear vehicle frame 2. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com