Lifting device for building material press rails

A lifting device, building material pressing technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of only being arranged in pits, the influence of the service life of hydraulic cylinders, and the shutdown of production lines, so as to meet the requirements of continuous production process and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0018] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

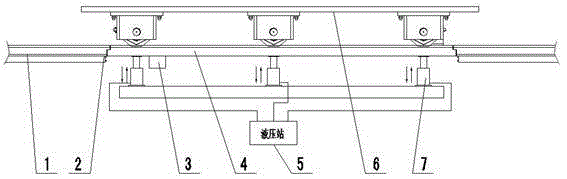

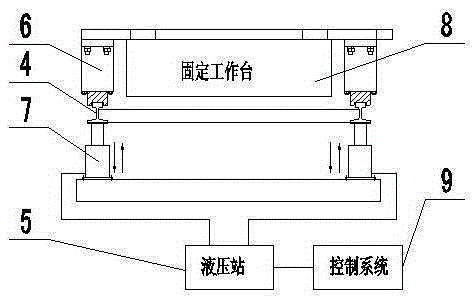

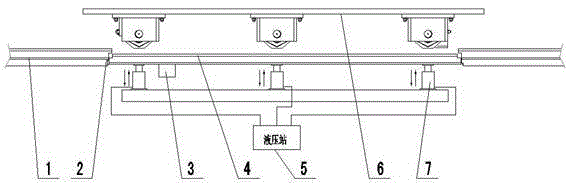

[0019] see figure 1 1. The lifting track 4 is located under the fixed workbench 8 at the lower part of the press and is docked with the fixed track 1 at both ends. The bottom of the lifting track 4 is equipped with a guide mechanism 3 and a plurality of hydraulic cylinders 7. The guide mechanism 3 can prevent the conveying board stack trolley 6 from When running on the lifting track 4, the track is sideways, and the fixed track 1 at one end of the lifting track 4 is provided with a position control sensor 2, which is used to detect the position of the lifting track 4, so as to ensure that the press conveys the pallet trolley 6 during the pressurization process. It can be suspended in the air, and after the pressuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com