Cleaning system for cleaning top cover of garbage can

A cleaning system and technology for trash cans, applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problem of low cleanliness of trash cans, and achieve increased cleaning range, high cleaning efficiency, and thorough cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

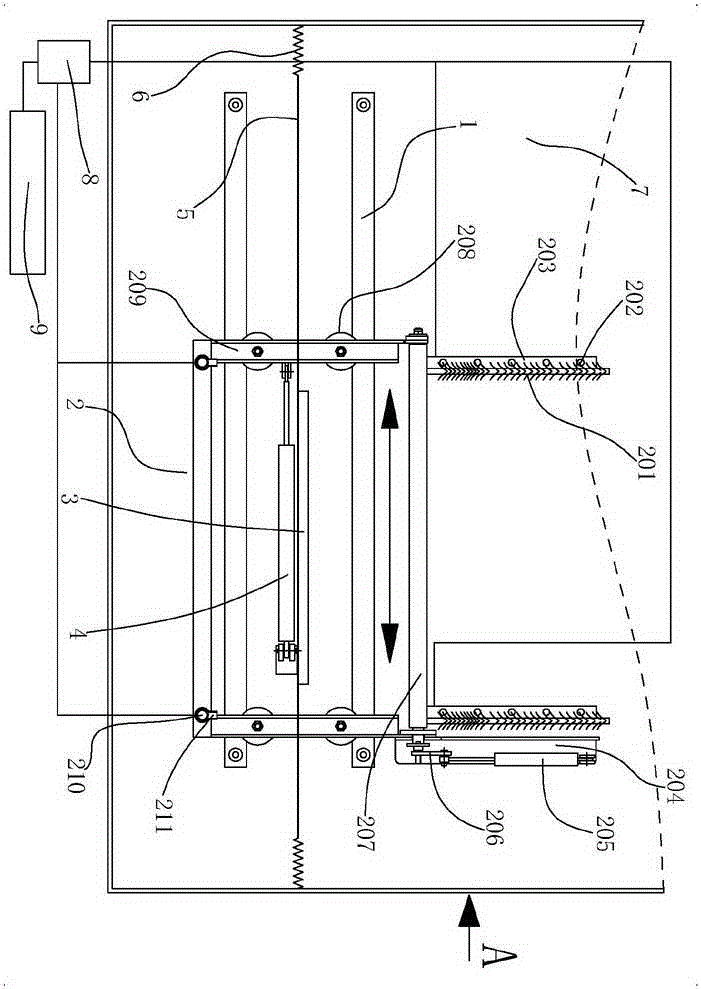

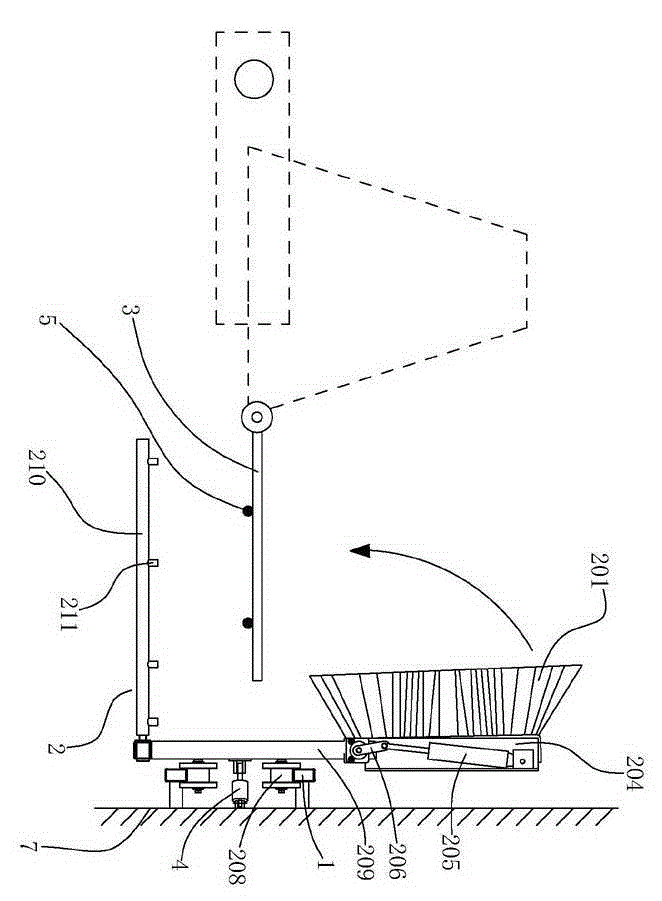

[0018] Such as Figure 1-2 As shown, a cleaning system for cleaning the top cover of the trash can includes a track assembly, a moving seat 2, a push-pull cylinder 4, a flexible limit assembly for holding the top cover 3 of the trash can, a water tank 9, and a water tank 9 for The water pump 8 from the water pump, the track assembly and the flexible limit assembly are all fixed on the wall 7 of the washing chamber; the mobile seat 2 includes a main frame 209, and the main frame 209 is rollingly matched with the track assembly and can reciprocate left and right along the track assembly. The cylinder barrel of the push-pull cylinder 4 is hinged on the wall 7 of the washing chamber, and the piston rod of the push-pull cylinder 4 is hinged with the main frame 209; A turning drive mechanism for turning over by driving the turning shaft 207; the axial length of the turning shaft 207 is consistent with the moving direction of the moving seat 2, and a brushing assembly is fixedly inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com