A pig feed conveying device

A technology of conveying device and pig feed, which is applied to animal feeding devices, cleaning devices, conveyor objects, etc., can solve problems such as disease, high viscosity, poor sprocket meshing, etc., to reduce the frequency of equipment maintenance, Ensure stability and ensure the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way. Any changes or improvements made based on the teaching of the present invention belong to the protection scope of the present invention.

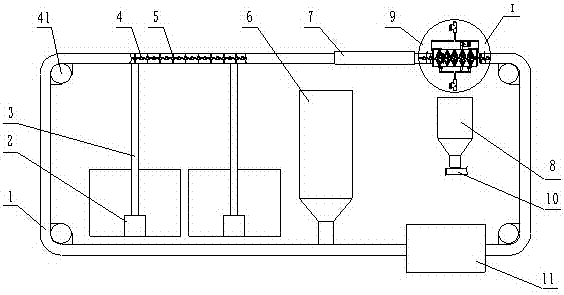

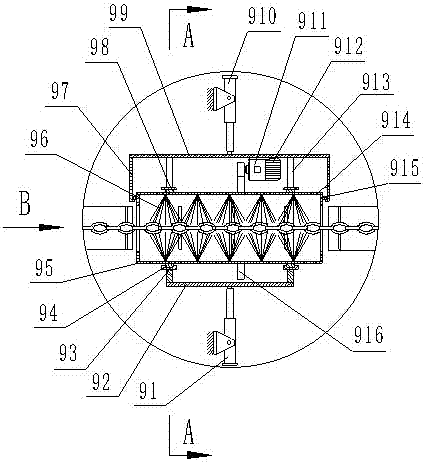

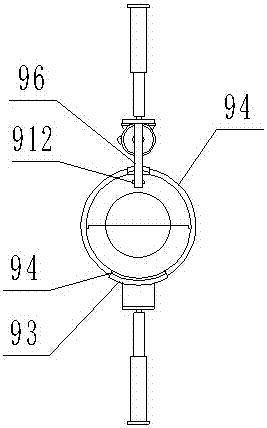

[0012] Such as Figure 1~4 As shown, the present invention comprises a feeding pipe 1, a food trough 2, a feeding pipe 3, a conveying chain 4, a material tower 6, and a driving device 11. The conveying chain 4 is provided with several evenly distributed cable trays 5, and the conveying chain 4 runs through The whole feed pipe 1 and the corners of the feed pipe 1 are equipped with a corner wheel device 41, and the feed pipe 1 is output by the drive device 11 and returns to the drive device 11 after passing through the outlet below the material tower 6 and the tops of several food troughs 2. The upper horizontal pipe section after the pipe 1 passes through the last trough 2 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com