Flower seed collecting vehicle

A technology for collecting trucks and flower seeds, applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problems of affecting the output of flower seeds, low labor efficiency, stuck debris, etc., to reduce the dust of flower seeds, improve the Labor efficiency, the effect of reducing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

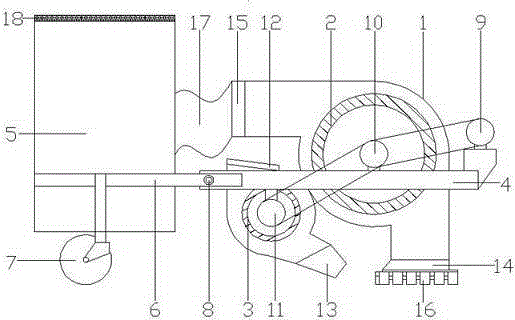

[0021] Such as figure 1 Shown, a kind of flower seed collecting vehicle comprises casing 1, large rectifying fan 2, small rectifying fan 3, hopper 5 and universal traveling wheel 7.

[0022] The casing 1 is wrapped on the outside of the large rectifier fan 2 and the small rectifier fan 3, and the outside of the casing 1 is fixedly connected to the traction frame 4; the outside of the hopper 5 is fixedly connected to the hopper frame 6, and the relative positions on both sides of the hopper frame 6 are fixed with universal travel Wheel 7; the beams on both sides of the traction frame 4 and the beams on both sides of the hopper frame 6 are respectively longer than the casing and the hopper 5; Connect; the front beam of the traction frame 4 is equipped with a primary transmission wheel 9 near one end; the side of the casing 1 on the same side as the primary transmission wheel 9 is successively provided with a secondary transmission wheel 10 and a tertiary transmission wheel conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com