Blade system, and corresponding method of manufacturing a blade system

A blade system and blade technology, applied in the field of blade devices, can solve problems such as expensive, difficult logic, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

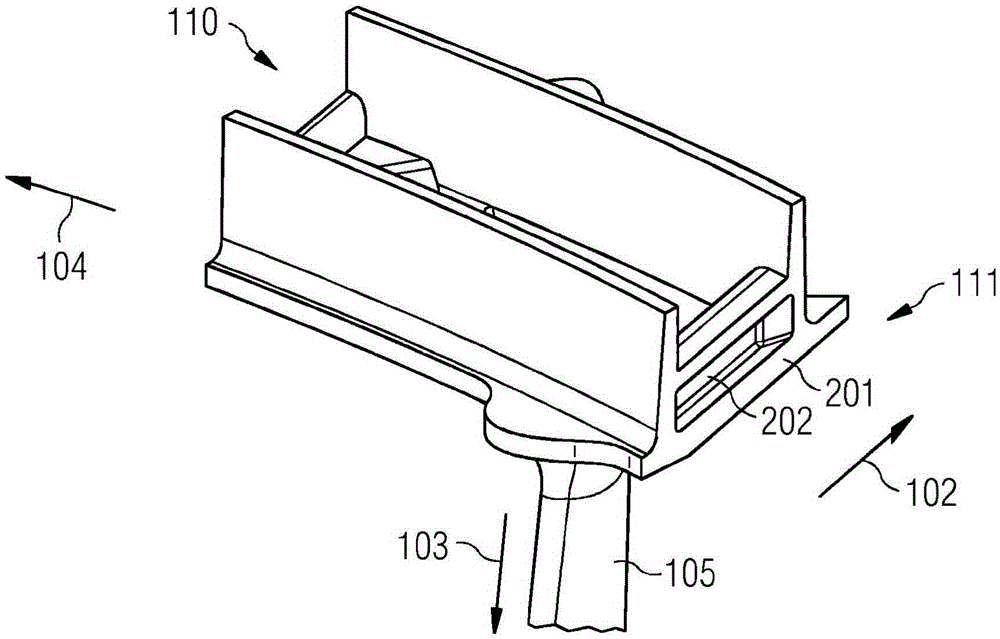

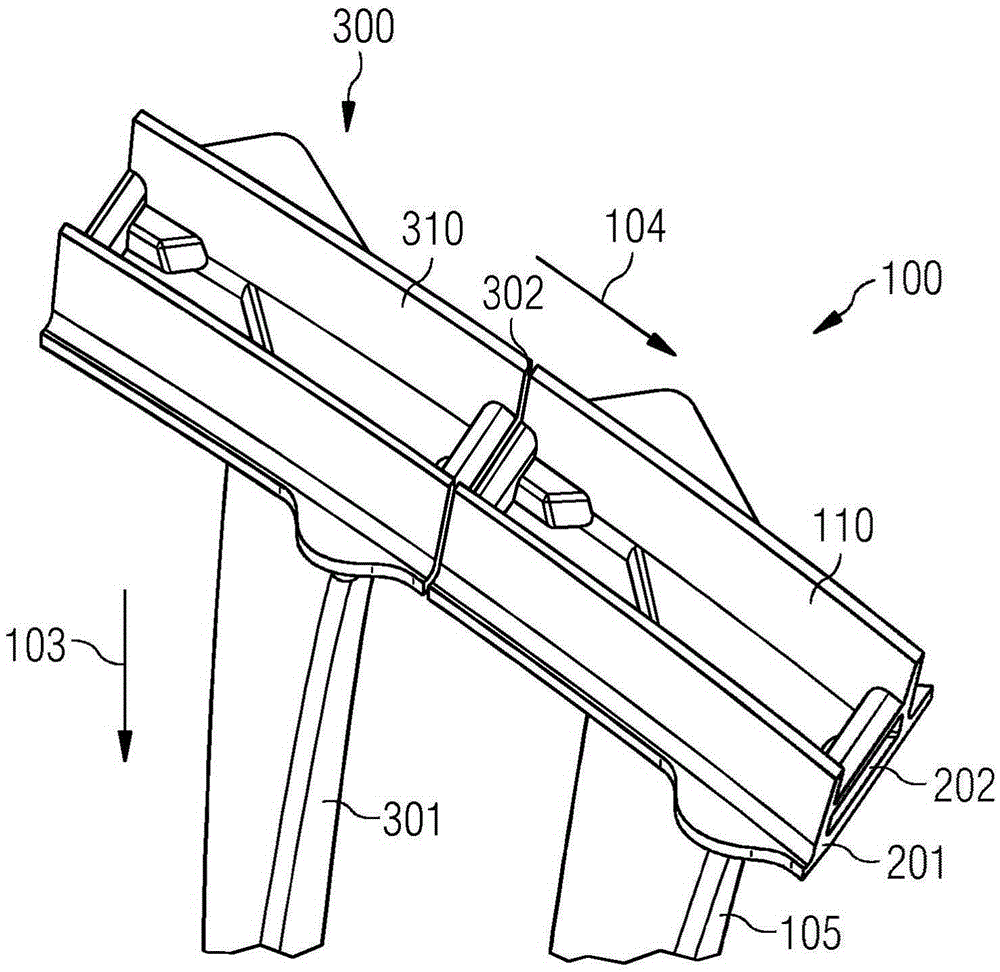

[0050] The illustrations in the drawings are schematic. It should be noted that similar or identical elements are provided with the same reference numerals in different figures.

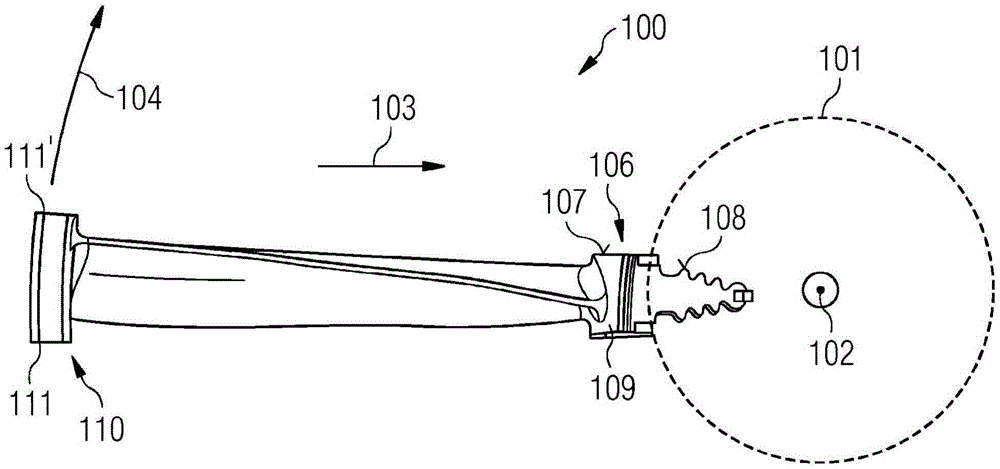

[0051] figure 1 A blade arrangement 100 for a gas turbine is shown. For better understanding, the extension and orientation of the features of the blade arrangement 100 are described with respect to a predefined direction of the rotor shaft 101 of the gas turbine (represented by dashed lines). The rotor shaft 101 includes an axial direction 102 parallel to the axis of rotation of the rotor shaft 101 . Furthermore, the radial direction 103 is depicted, which points to the central axis (rotation axis) of the rotor shaft 101 . The circumferential direction 104 is perpendicular to the axial direction 102 and the radial direction 103 . In the circumferential direction 104, a plurality of blade arrangements 100 may be arranged one after the other.

[0052] The blade arrangement 100 includes a shroud 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com