Thyristor converter valve module

A thyristor converter valve and valve module technology, which is applied in the field of valve modules and thyristor converter valve valve modules, can solve the problems of reducing installation efficiency and reduction, and achieve the effects of reducing weight, ensuring strength and insulation, and maintaining no imbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to better understand the present invention, the content of the present invention will be further described below in conjunction with the accompanying drawings and examples.

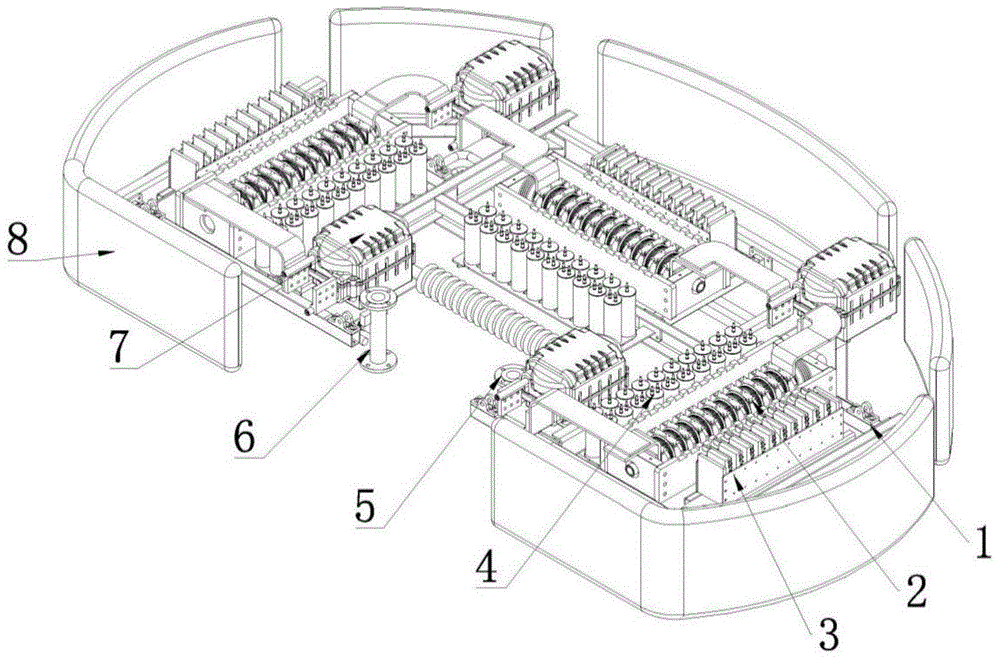

[0041] The thyristor converter valve module provided by the present invention is as figure 1 As shown: the valve module is in the shape of "concave", including the combination frame 1, the thyristor pressing mechanism 2 installed in the combination frame 1, the damping capacitor 4, the saturated reactor 7, the gate box 3 and the water cooling system, and the combination Shielding cover 8 on the periphery of the frame.

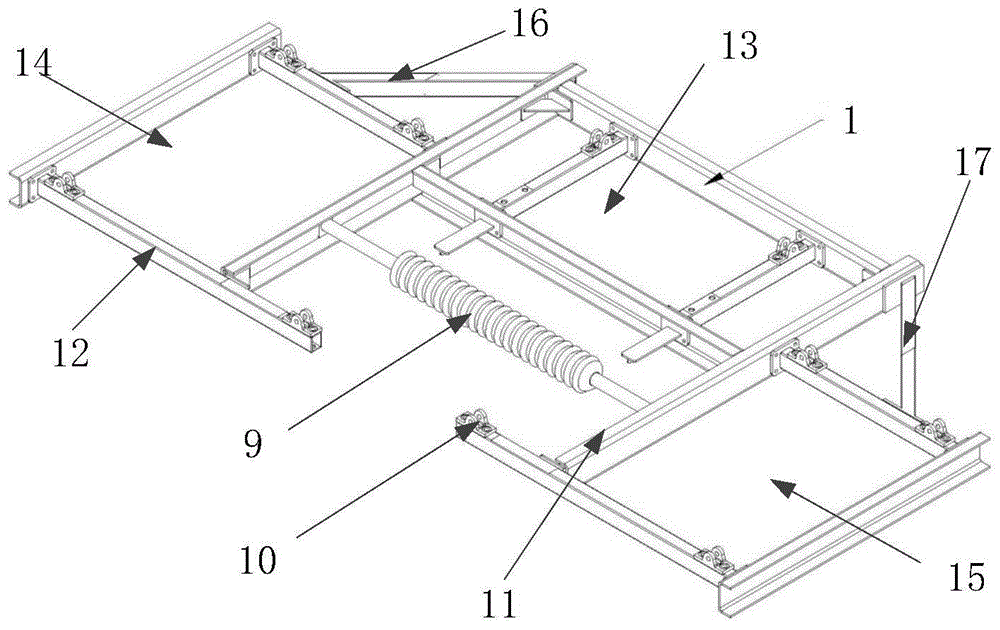

[0042] Such as figure 2As shown, the combined frame 1 is used as the bearing matrix of all components in the valve module, and is composed of several metal beams 12, non-metallic insulating beams, cross-brace insulators 9 and related link accessories, which can not only ensure the structural strength of the valve module, but also meet the Valve module high voltage insula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com