Cable joint testing device for vehicle lights

A technology of cable connector and testing device, which is applied in the field of cable connector testing device for automotive lights, can solve the problems of damaged cable connector, low detection efficiency, long detection time, etc., and achieve the effects of fast loading and unloading, light operation, and low manufacturing and use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

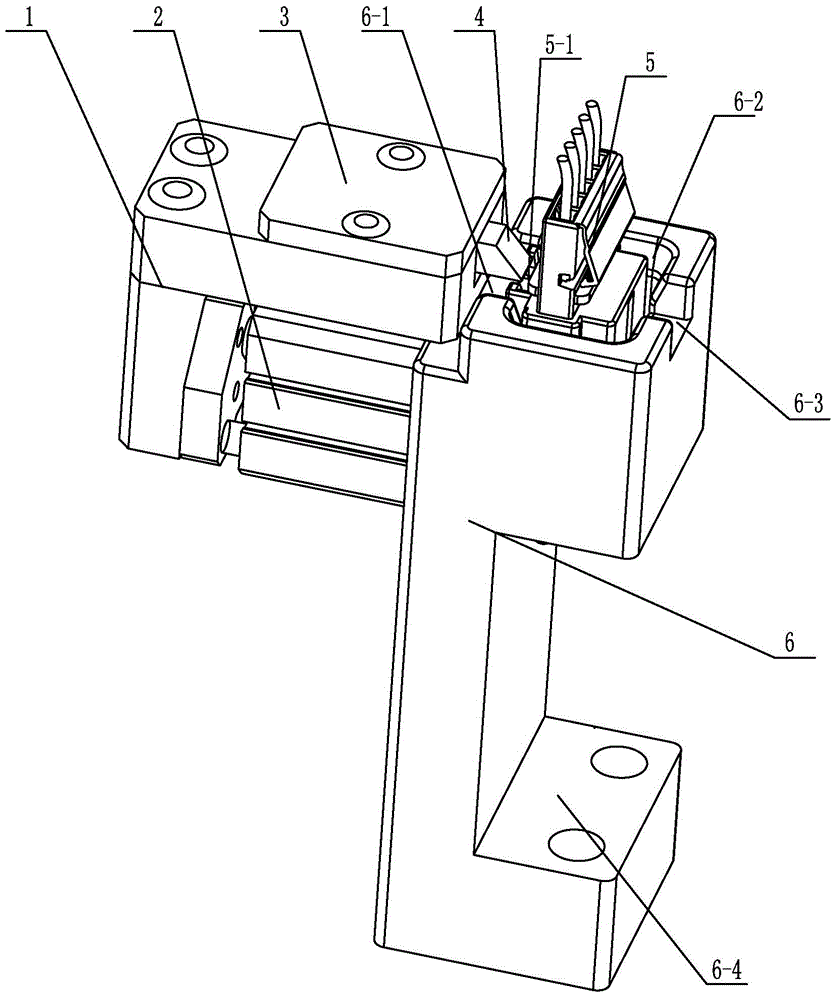

[0015] See Figure 1~2 As shown, the cable joint testing device for vehicle lamps of the present invention includes an insulating support 6 , a tab 4 and a cylinder 2 for controlling the lateral movement of the spring seat 1 .

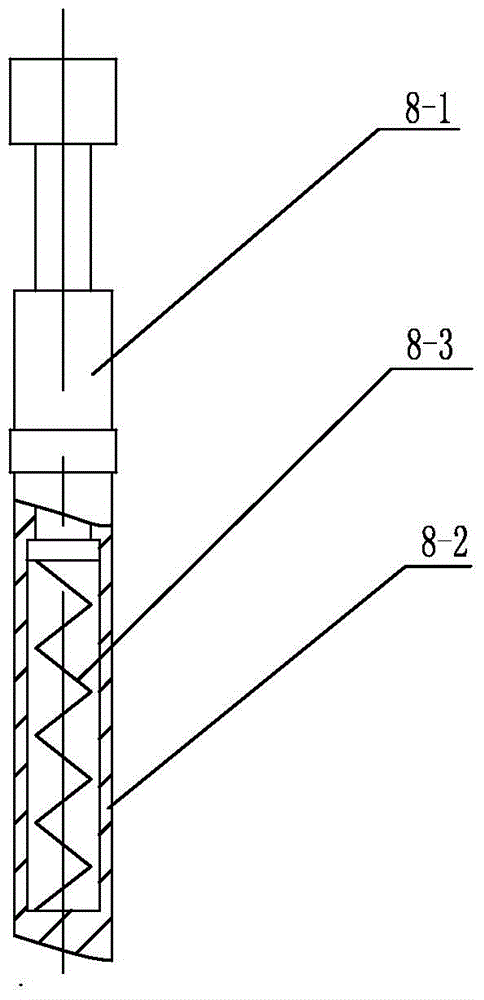

[0016] See figure 1 As shown, the insulating support 6 of the present invention includes a lower base 6-4 for fixing on the workbench and an upper insertion slot 6-2 for placing the cable connector 5, and at least two groups of probe assemblies 8 are arranged in On the insulating support 6, two groups of probe assemblies 8 are connected with the power supply to form a loop, see figure 1 , 2 As shown in and 4, the present invention adopts five groups of control needles to be connected with the power supply and form a loop to detect whether the four bulbs in the car lights are on. See Figure 1~3 As shown, the needle control assembly 8 of the present invention includes a fixed rod 8-2, a movable rod 8-1 and an ejection spring 8-3, and the fixed rod 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com