Collapsible loess area building foundation reinforcing pile and pile pressing construction method thereof

A technology for collapsible loess and foundation reinforcement, which is applied in foundation structure engineering, construction, foundation structure repair, etc., and can solve the problem that it is difficult to penetrate the self-weight collapsible loess layer, the lateral resistance of piles cannot be considered, and the building's self-weight is small and other problems, to achieve the effect of improving the jacking efficiency, reducing the total pile length, and improving the strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

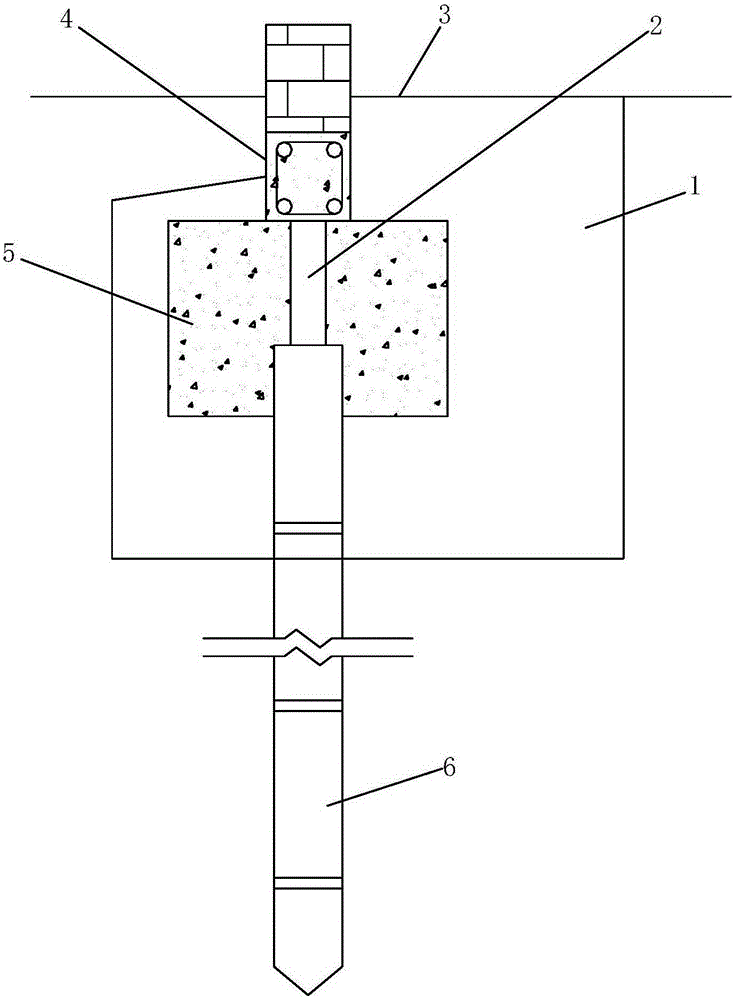

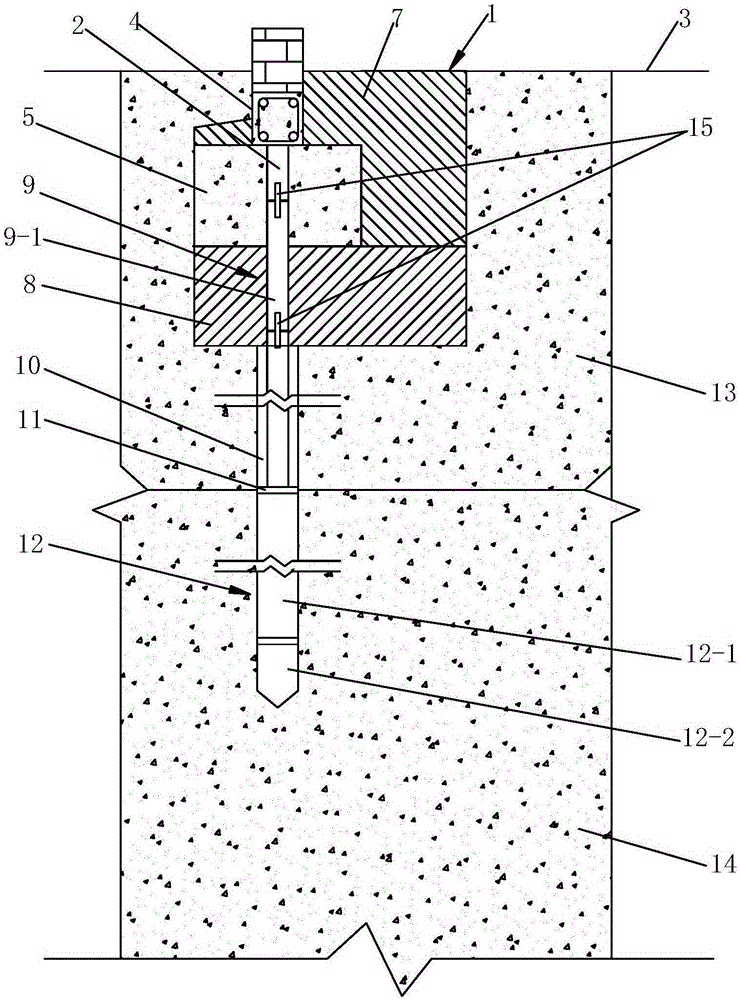

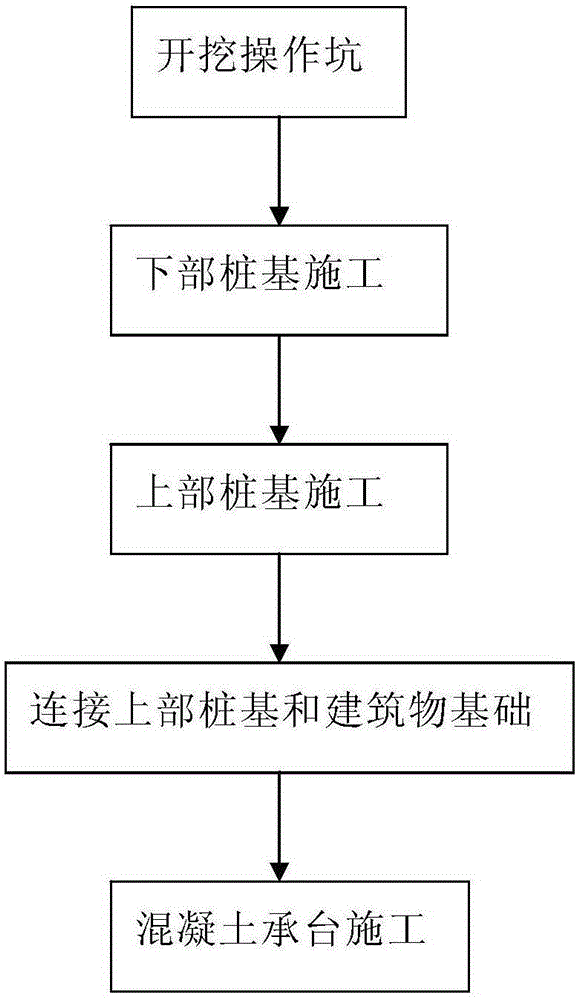

[0043] Such as figure 2 A kind of building foundation reinforcement pile in the collapsible loess area shown, comprises the upper pile foundation 9, the lower pile foundation 12, the underpinning steel pipe 2 and the operation pit 1 opened in the self-weight collapsible loess layer 13, the operation The pit 1 extends from the ground 3 to below the building foundation 4, and the operation pit 1 is provided with a lower backfill soil layer 8 and an upper backfill soil layer 7 above the lower backfill soil layer 8, and the upper backfill soil layer A concrete cap 5 connected to the lower end surface of the building foundation 4 is provided in the layer 7, the lower pile foundation 12 is arranged in the non-collapsible loess layer 14, the lower end of the upper pile foundation 9 is connected to the lower pile foundation 12, the upper end of the upper pile foundation 9 passes through the self-weight collapsible loess layer 13 and the lower backfill soil layer 8 in sequence and ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com