Dovetail flip bucket and fitting slope aeration method and structure

A technology of swallowing ridges and slopes, which is applied in water conservancy projects, sea area projects, coastline protection, etc., and can solve problems such as poor aeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

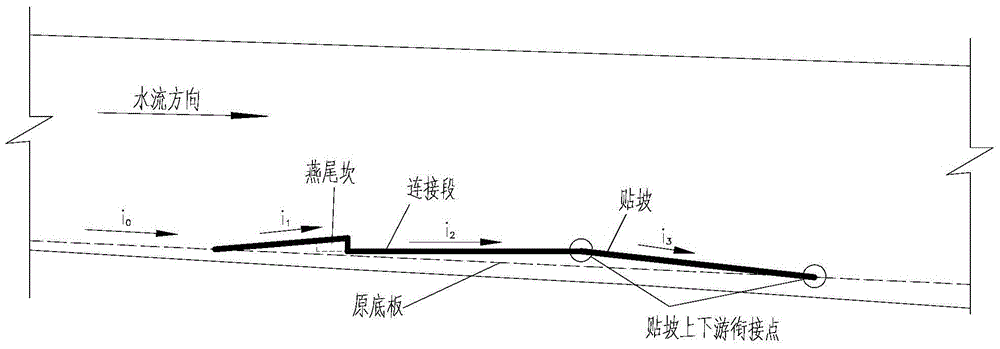

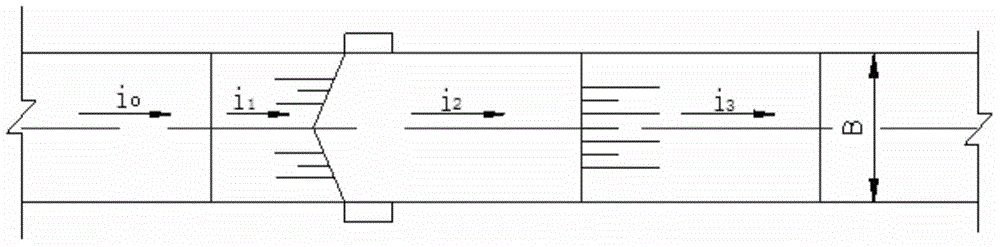

[0021] Such as Figure 1-3 As shown, the aeration structure of this embodiment consists of a dovetail groove at the end of the upstream end ( figure 2 Middle Yanwei ridge section, slope i 1 ), and the slope at the downstream end that is larger than the slope of the bottom plate of the discharge channel ( figure 2 Middle paste slope section, slope i 3 ) and the connecting section connecting the ridge and the slope ( figure 2 middle link, slope i 2 )composition. The slope and the connecting section and the downstream original floor are connected by points (point connection on the section view and straight line connection on the plan view). The connecting section is a flat slope (i 2 =0).

Embodiment 2

[0023] Such as Figure 4 As shown, the aeration structure of this embodiment is similar to that of Embodiment 1, the difference is that the slope and the upstream connection section are connected by a convex arc curve, and the slope and the downstream bottom plate are connected by a concave arc curve (the arc curve is shown in the cross-sectional view Connection, surface connection in plan view). The connection form can also be a straight line in the section (a straight line connection in a section view, and a plane connection in a plan view) or other curved connections.

Embodiment 3

[0025] Such as Figure 5-7As shown, the aeration structure of this embodiment is similar to that of Embodiment 1, the difference is that the slope of the bottom plate after the slope is pasted is smaller than the slope of the upstream bottom plate (i 4 ﹤i 0 ), the slope and the upstream connection section are connected by a convex arc curve, the slope and the downstream floor are connected by a concave arc curve, and the slope of the connection section is a positive slope (i 2 >0).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com