Blown air rectifying device of chemical fiber spinning equipment

A technology of rectifying device and blowing device, which is used in fiber processing, textile and papermaking, filament/thread forming, etc., can solve the problems of large wind speed unevenness, high energy consumption, low wind speed, etc., and achieve uniform wind pressure. , The wind speed is uniform and stable, and the effect of blowing balance is guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention will be described in detail below, and the "upper" side mentioned in the specification is the appended figure 1 The left side of the manual, the "below" mentioned in the manual refers to the attached figure 1 on the right side of the .

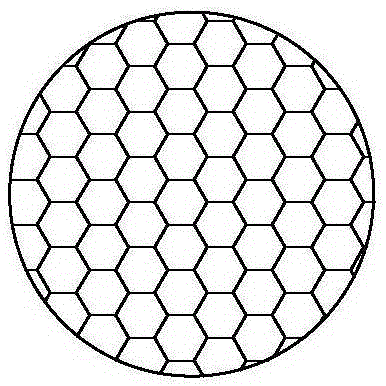

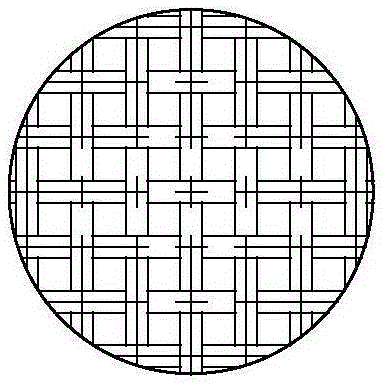

[0020] A blowing and rectifying device for chemical fiber spinning equipment, the blowing and rectifying device is installed in the air volume regulating device of the chemical fiber spinning equipment, and is located at the air outlet of the air volume regulating device. The blowing and rectifying device includes a multi-hole plate 1, a filter screen 2, a lower flange 3, an upper flange 4, a honeycomb plate 5, an air equalizing net 6, and a protective net 7 arranged in sequence from bottom to top, wherein the honeycomb plate 5, the equalizing net The outer side of wind net 6 and protection net 7 is provided with honeycomb panel fram...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com