220kv epoxy type insulating copper casing

An epoxy insulation, 220kv technology, applied in the electrical field, can solve the problems of reducing the stability and service life of power cables, unsatisfactory electrical insulation effect, unreasonable structural design, etc., to improve the safety of use, improve the overall performance and use Longevity, reasonable effect of overall structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

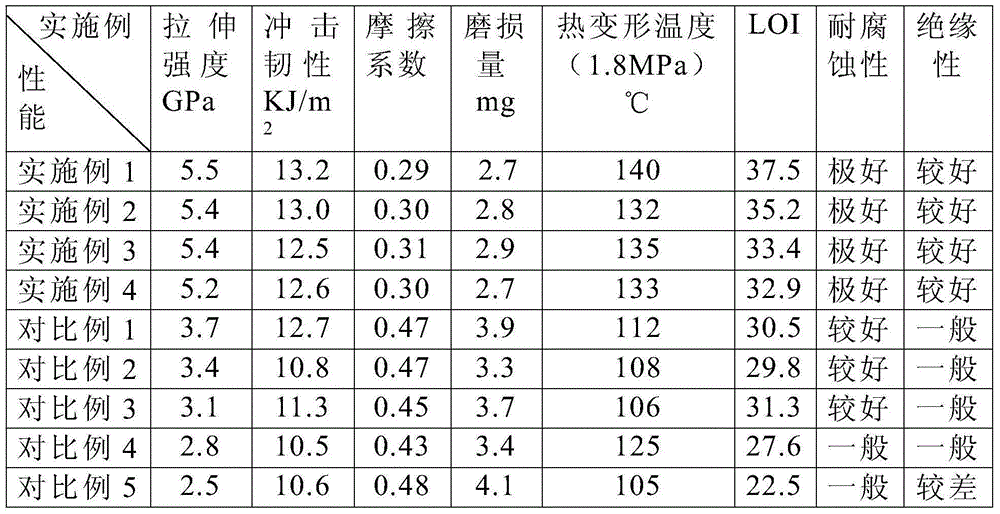

Embodiment 1

[0069] Both the left insulating layer and the right insulating layer described in this embodiment are made of epoxy resin composite material, and the epoxy resin composite material includes the following components and weight percentages:

[0070] Epoxy resin: 40wt%;

[0071] E-glass fiber: 6wt%;

[0072] Nano Sb 2 o 3 : 5wt%;

[0073] Decabromodiphenyl ether (FR-10): 1.5wt%;

[0074] Curing agent: 3wt%;

[0075] Curing agent accelerator: 3wt%;

[0076] The balance is silica.

[0077] Wherein, the epoxy resin is a phosphorus-containing epoxy resin, and the phosphorus content is 3%; the alkali-free glass fiber is a chopped glass fiber, and the length of the chopped glass fiber is 2.0-5.0mm, and the diameter is 8- 12 μm; the silicon dioxide is a mixture including silicon dioxide particles I, silicon dioxide particles II and silicon dioxide particles III (silicon dioxide particles I 12%, silicon dioxide particles II 70%, and the balance is silicon dioxide Particle III), t...

Embodiment 2

[0080] Both the left insulating layer and the right insulating layer described in this embodiment are made of epoxy resin composite material, and the epoxy resin composite material includes the following components and weight percentages:

[0081] Epoxy resin: 35wt%;

[0082] E-glass fiber: 8wt%;

[0083] Nano Sb 2 o 3 : 5wt%;

[0084] Decabromodiphenyl ether (FR-10): 1.2wt%;

[0085] Curing agent: 4wt%;

[0086] Curing agent accelerator: 2wt%;

[0087] The balance is silica.

[0088] Wherein, the epoxy resin is phosphorus-containing epoxy resin, and the phosphorus content is 2.5%; the alkali-free glass fiber is chopped glass fiber, and the length of the chopped glass fiber is 2.0-5.0mm, and the diameter is 8- 12 μm; the silicon dioxide is a mixture including silicon dioxide particles I, silicon dioxide particles II and silicon dioxide particles III (14% silicon dioxide particles I, 72% silicon dioxide particles II, and the balance is silicon dioxide Particle III), the...

Embodiment 3

[0091] Both the left insulating layer and the right insulating layer described in this embodiment are made of epoxy resin composite material, and the epoxy resin composite material includes the following components and weight percentages:

[0092] Epoxy resin: 50wt%;

[0093] E-glass fiber: 6wt%;

[0094] Nano Sb 2 o 3 : 4wt%;

[0095] Decabromodiphenyl ether (FR-10): 1wt%;

[0096] Curing agent: 2wt%;

[0097] Curing agent accelerator: 4wt%;

[0098] The balance is silica.

[0099] Wherein, the epoxy resin is a phosphorus-containing epoxy resin, and the phosphorus content is 4%; the alkali-free glass fiber is a chopped glass fiber, and the length of the chopped glass fiber is 2.0-5.0mm, and the diameter is 8- 12 μm; the silicon dioxide is a mixture including silicon dioxide particles I, silicon dioxide particles II and silicon dioxide particles III (15% of silicon dioxide particles, 65% of silicon dioxide particles, and the balance is silicon dioxide Particle III), th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com