Automatic arch breaking device for ammonium nitrate fuel oil explosive mixing and charging vehicle

A technology for ammonium explosives and mixed trucks, applied in the directions of packaging, transportation and packaging, containers, etc., can solve the problems of falling, high labor intensity, delay in production, etc., to improve quality, avoid potential safety hazards, and reduce work intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

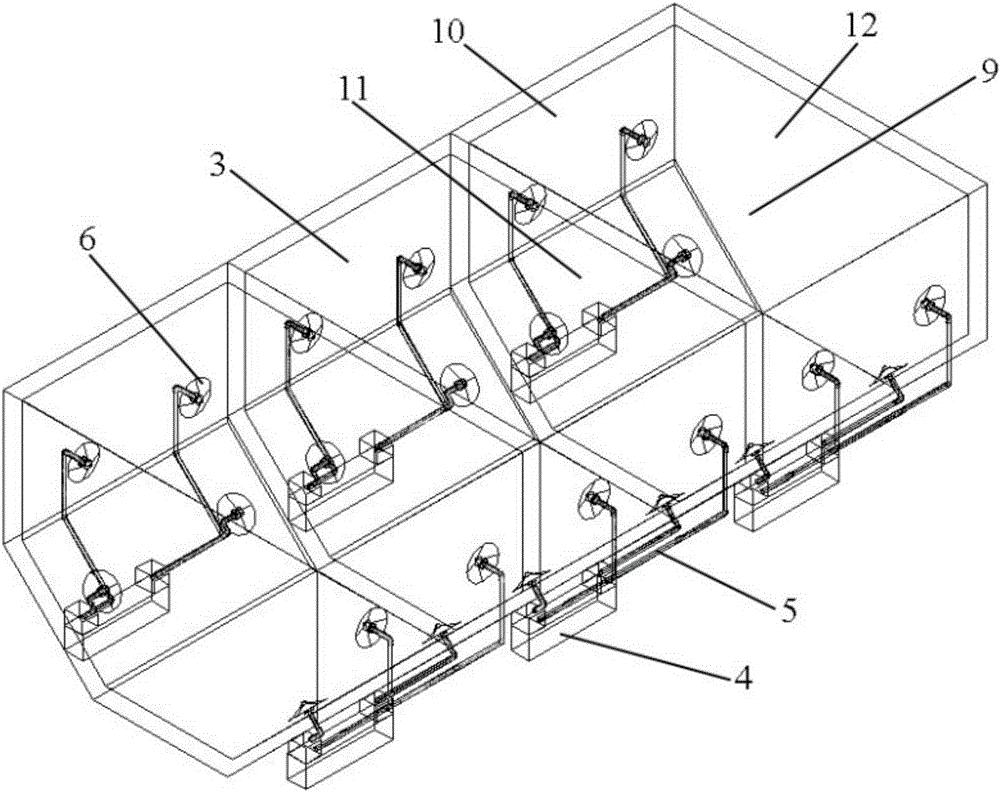

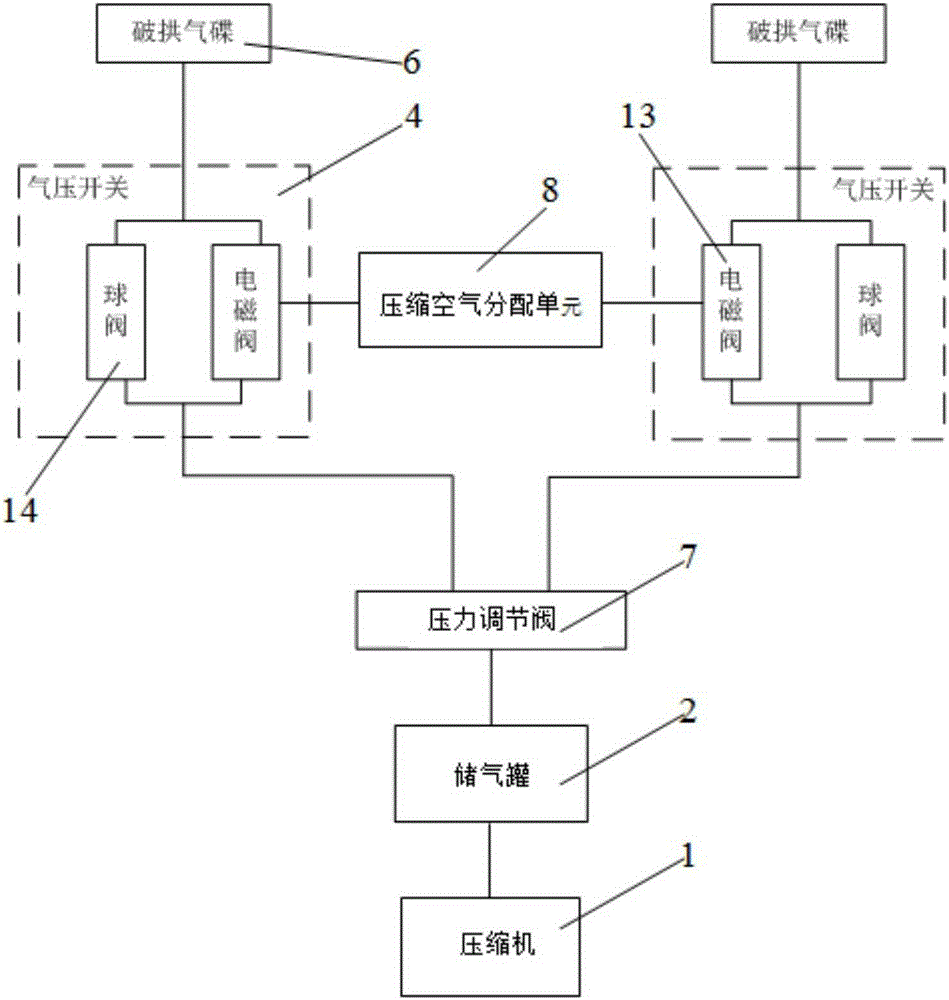

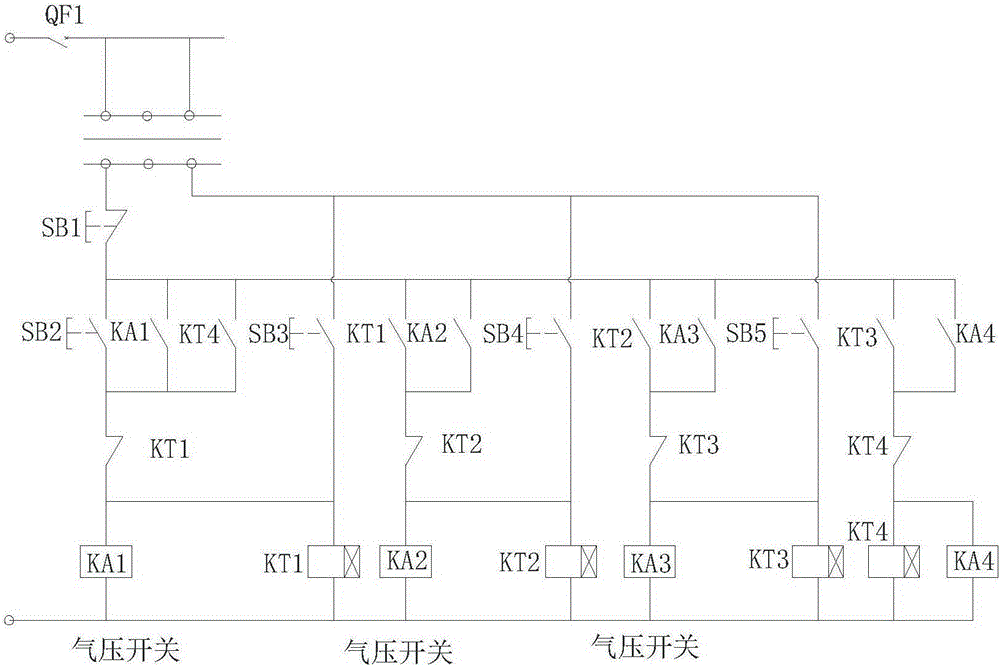

[0021] Preferred embodiments of the present invention will be described below with reference to the drawings.

[0022] like figure 1 and 2 As shown, the present invention is an automatic arch-breaking device for ammonium oil explosive mixed loading vehicle, comprising a compressor 1 for driving the mixed loading vehicle, a gas storage tank 2 connected with compressor 1, a material for storing ammonium oil explosive raw material Bin 3, air pressure switch 4 connected to air storage tank 2, compressed air pipe 5 connected to air pressure switch 4, several arch-breaking air discs 6 installed on the inner wall of silo 3, pressure connected to air storage tank 2 and air pressure switch 4 The regulating valve 7 and the compressed air distribution unit 8 electrically connected with the air pressure switch 4 .

[0023] The silo 3 is provided with a plurality of storage cavities 9 for storing porous granular ammonium nitrate. A plurality of arch-breaking air discs 6 are arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com