Vibration system for vehicle seat

A vibration system and vehicle seat technology, which is applied in the field of vibration system for vehicle seats, can solve the problems of large manual force, application, and uncoordinated comfort requirements, and achieve the effect of cheap manufacturing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

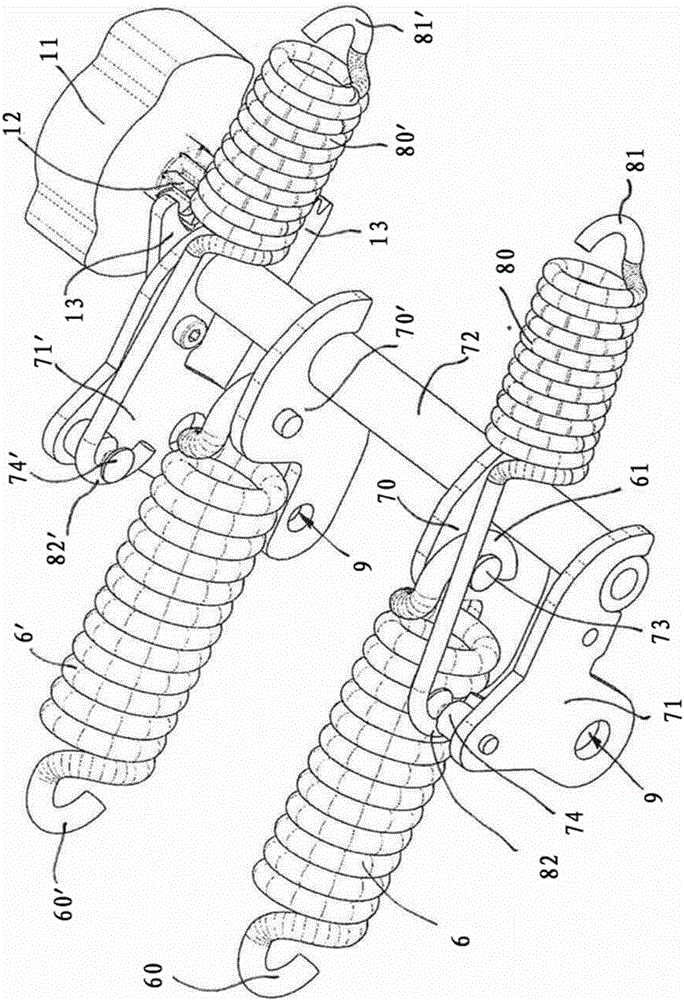

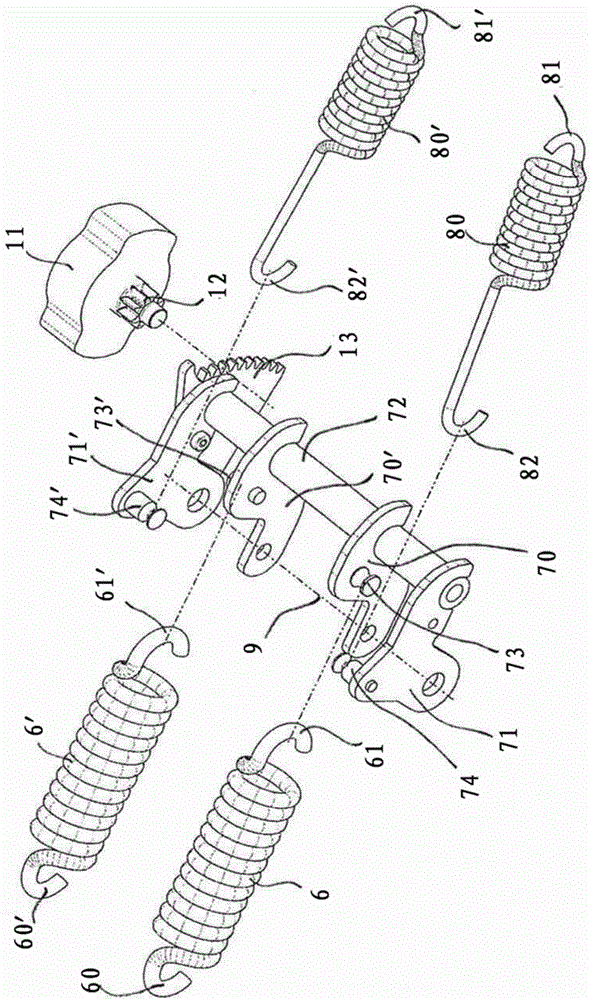

[0022] figure 1 An exemplary embodiment of the vibrating system according to the invention is shown viewed obliquely. The vibratory system consists of a conventional cross tie system (Scherenlenker system) with a lower frame 1 and an upper frame 2, which are connected to each other via two cross members, an outer cross member 3 and an inner cross member 4 to enable them to vary their vertical spacing from each other. For this purpose, the two cross members 3 , 4 are connected to each other in such a way that they can revolve around a horizontally extending axis of rotation 5 (see Image 6 ) to rotate. At the same time, one of its two ends is connected to one of the two frames 1 , 2 each about a fixed axis and is made movable relative to the other frame 2 , 1 by its corresponding other end. support. Since such systems are known in the prior art to those skilled in the art, they will not be described in detail below.

[0023] In order to isolate the vibrations occurring on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com