Three-dimensional molded anastomat anvil of anastomat and anastomat molding method

A technology of three-dimensional forming and anastomotic staples, which is applied in the field of medical devices, can solve problems such as bleeding at the incision edge, bleeding at the incision end, and bleeding caused by tissue compression damage, and achieve uniform suture openings, uniform anastomotic joints, and avoid local intersections.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

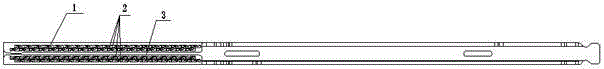

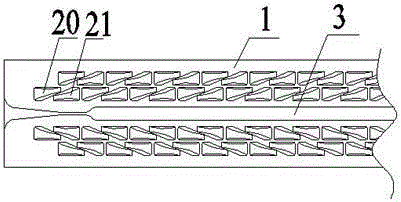

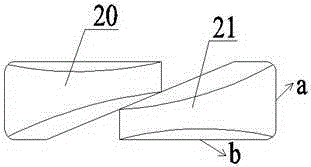

[0020] see Figure 1 to Figure 4 , Embodiment 1 of the present invention: a nail anvil for three-dimensional forming of staples, comprising an anvil body 1, which is provided with four rows of nail forming grooves and a cutting knife guide groove 3, and the two sides of the cutting knife guide groove 3 Both are provided with two rows of nail forming grooves, and the two rows of nail forming grooves located on the same side of the cutter guide groove 3 are arranged alternately; each row of nail forming grooves is provided with a number of staple forming grooves 2, and each staple forming groove 2. It consists of two identical holes. The cross-section of the two identical holes is an irregular triangle. The irregular triangle in the cross-section of the hole has a group of adjacent sides perpendicular to each other. Please refer to image 3 , in the figure, a represents side a, and b represents side b; side a of the staple forming slot 2 is perpendicular to side b.

[0021] In ...

Embodiment 2

[0024] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in this embodiment, the length of the staple forming slot 2 is 5.5 mm. The length of the base a of the irregular triangle formed by the cross-section of the first slot 20 and the second slot 21 is 1.8 mm.

Embodiment 3

[0025] Embodiment 3: The difference between this embodiment and Embodiment 1 is that in this embodiment, the length of the staple forming slot 2 is 5.2 mm. The length of the base a of the irregular triangle formed by the cross-section of the first slot 20 and the second slot 21 is 1.5 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com