Adjustable speed permanent magnet eddy current coupling

A permanent magnet eddy current and coupling technology, applied in the direction of electrical components, electromechanical devices, etc., can solve the problems of large changes in output torque and output speed, inability to achieve soft start, easy to burn eddy current rotors, etc., to reduce maintenance frequency, Ingenious structure, to achieve the effect of torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

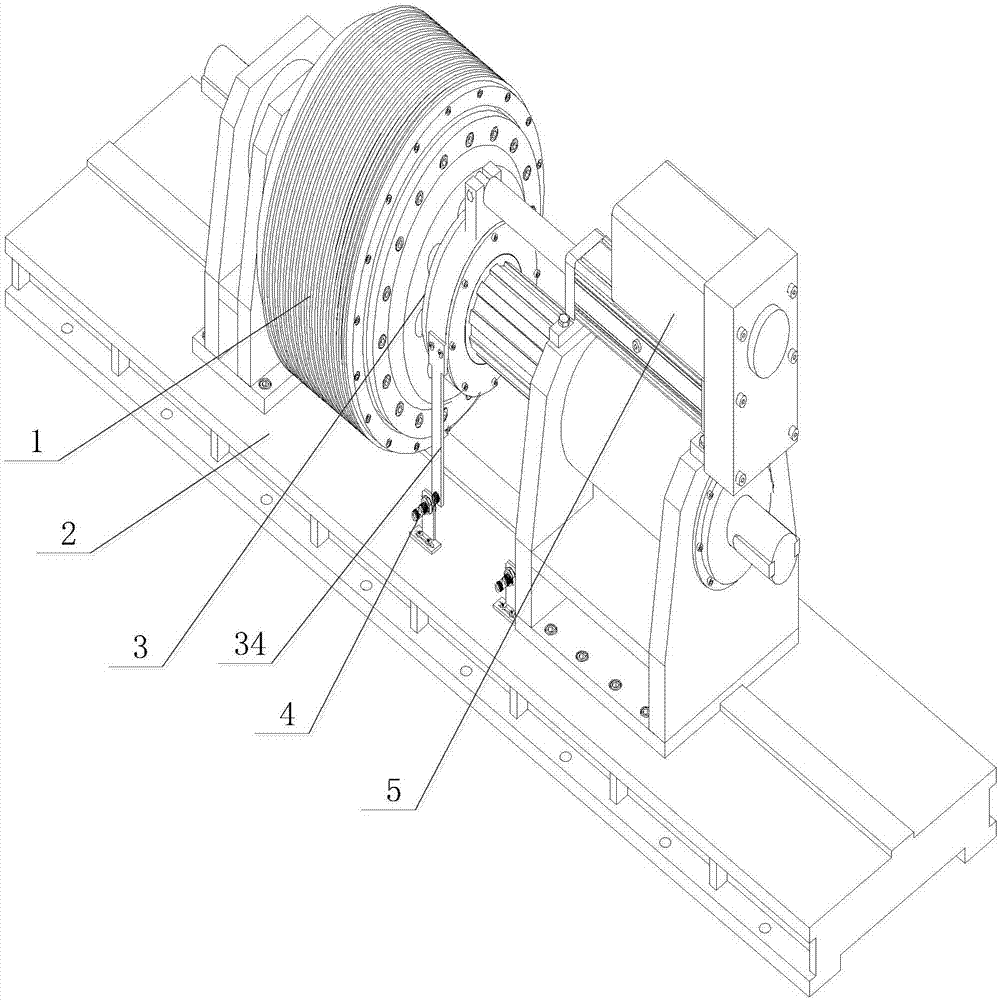

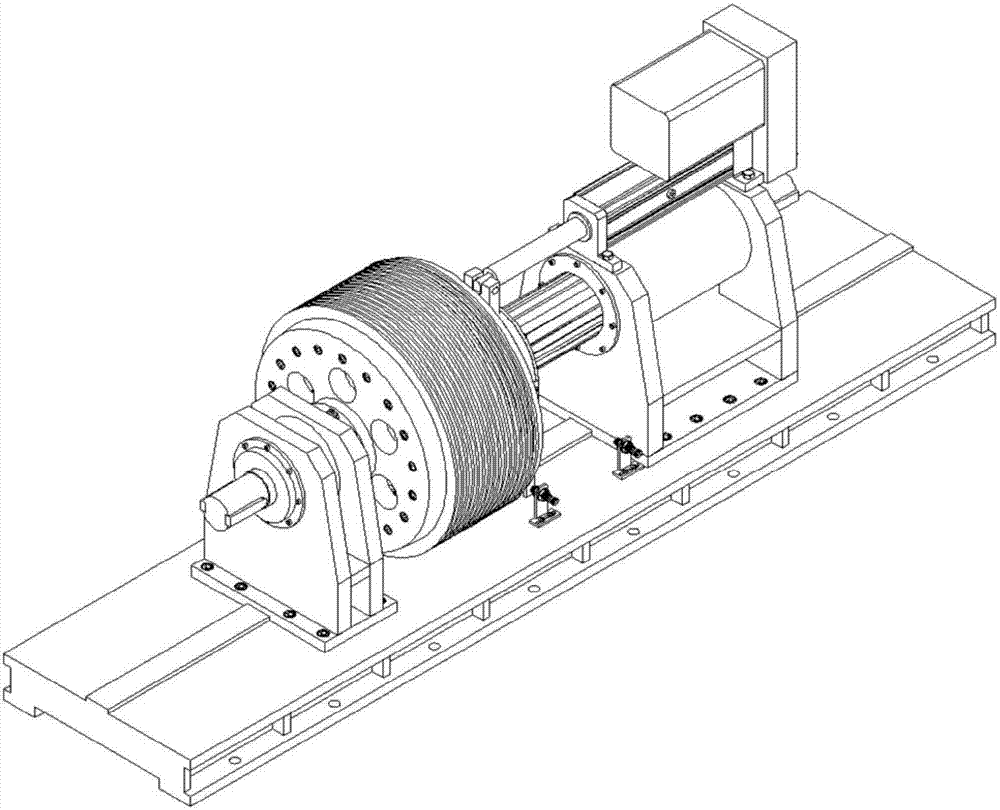

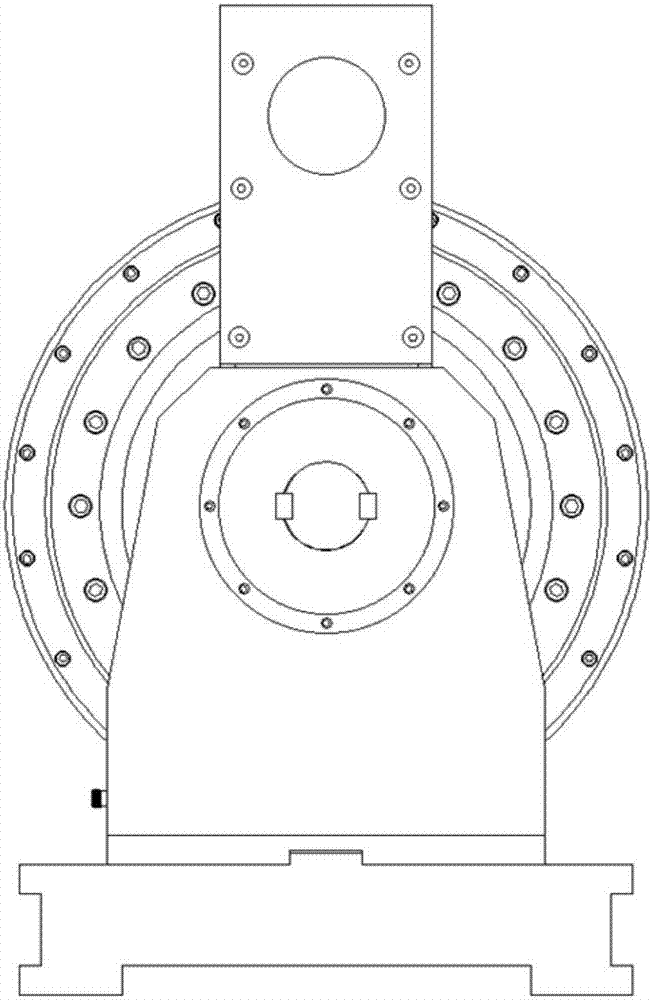

[0051] Embodiments according to the present invention will be described in detail below with reference to the accompanying drawings.

[0052] As shown in the drawings, a speed-regulating permanent magnet eddy current coupling includes: an active rotor mechanism 1, which is mainly composed of an eddy current rotor 6, an active yoke rotor 7, a cooling fin 23, a driving shaft 11 and an active support frame 8 , the eddy current rotor 6 and the active yoke rotor 7 adopt wedge connection, interference fit, to ensure the coaxiality between the eddy current rotor 6 and the active yoke rotor 7, and both ends of the eddy current rotor 6 are bolted to the active yoke rotor 7 connection, so that the two rotors are firmly connected when rotating at high speed, and ensure the reliability of torque transmission; the driven rotor mechanism 3 is mainly composed of permanent magnet 13, magnetic pole inlay 14, driven yoke rotor 15, load shaft 22, driven The support frame 29 and the limit switch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com