Formation method of PMOS transistor

A technology of transistors and semiconductors, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as sufficient stress applied to the channel region, poor performance of PMOS transistors, etc., to improve hole mobility and improve performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

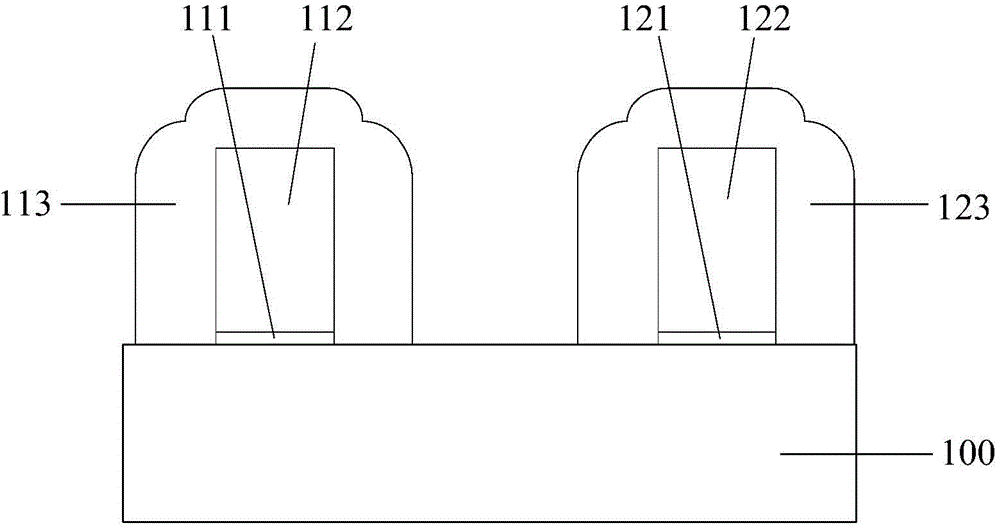

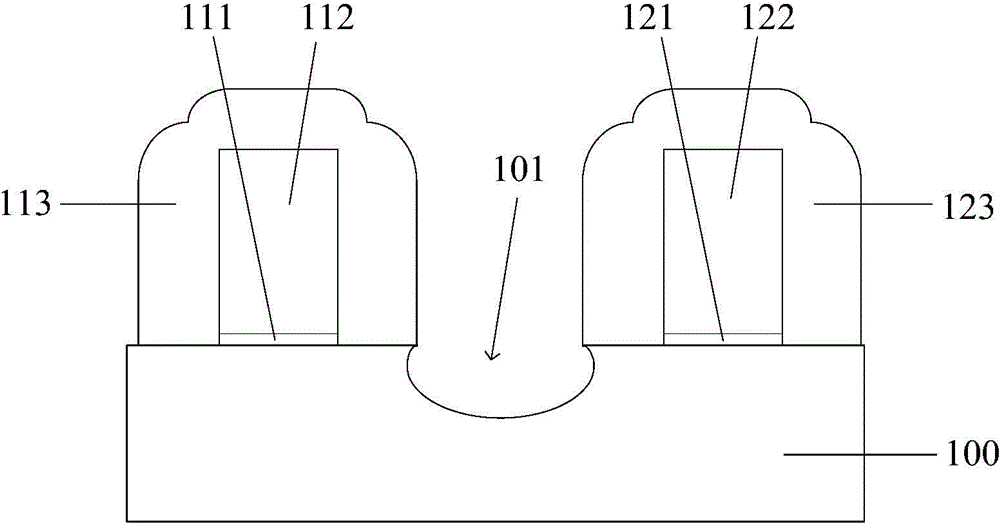

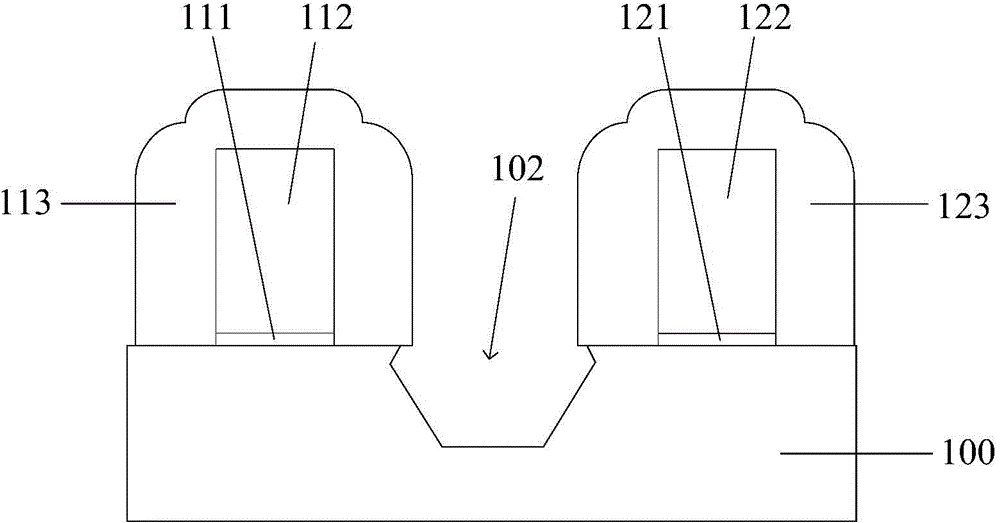

[0035] As mentioned in the background, in the existing PMOS transistors, the epitaxial silicon germanium layer is too far away from the channel region, so sufficient stress cannot be applied to the channel region, and the performance of the PMOS transistor is not good. Further analysis shows that this is because the thickness of the sidewall formed by the existing PMOS transistor formation method is relatively large, and when the groove is formed by a dry etching process, the distance from the sidewall of the groove to the channel region is relatively long. The distance between the epitaxial silicon germanium layer that subsequently fills the groove and the channel region is relatively long, therefore, the epitaxial silicon germanium layer cannot act well on the channel region.

[0036] For this reason, the present invention provides a new method for forming a PMOS transistor. The method first forms a first groove, then forms a depression on the side wall of the first groove, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com