Weld image segmentation method

An image segmentation and image technology, applied in the field of image processing, can solve the problems of reduced image contrast, lack of image details, long running time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

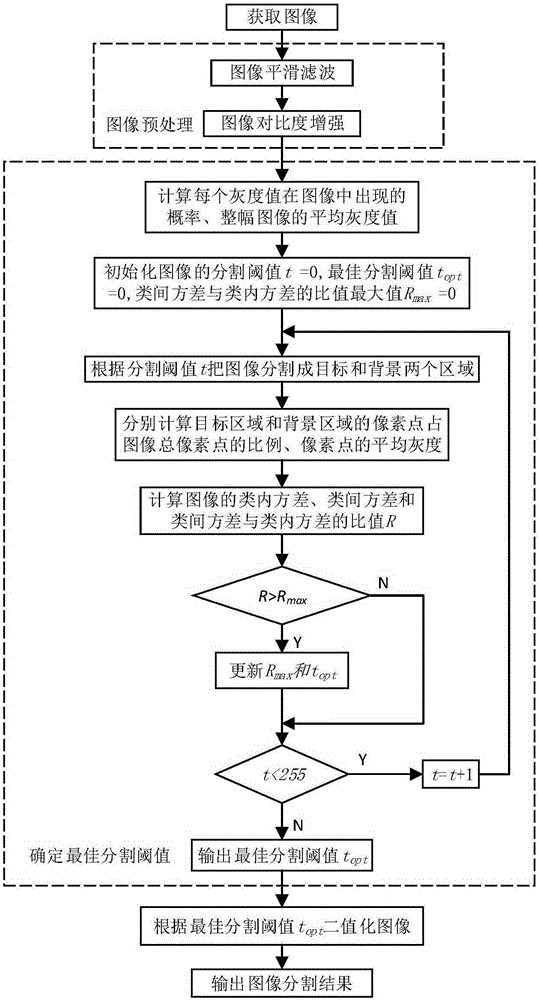

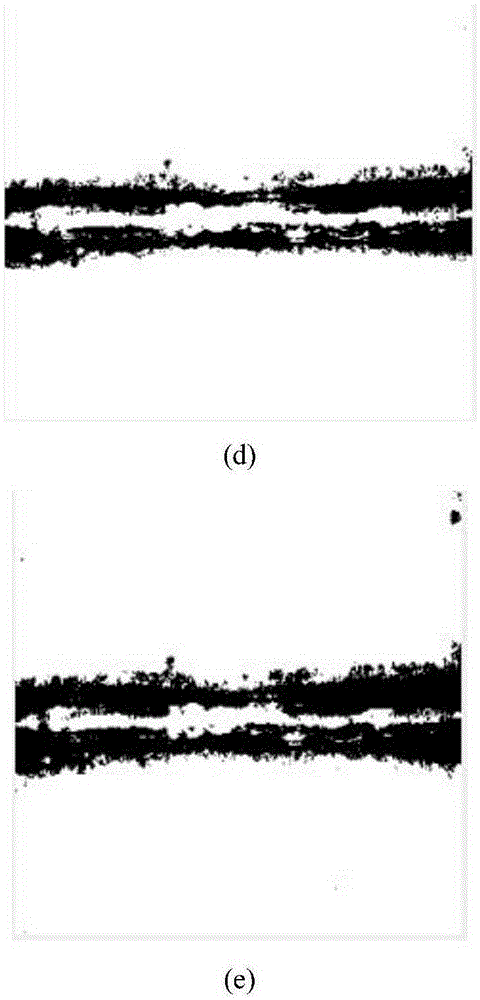

[0050] Attached below figure 1 The specific implementation manners of the present invention will be further described.

[0051] Step 1. Get the image;

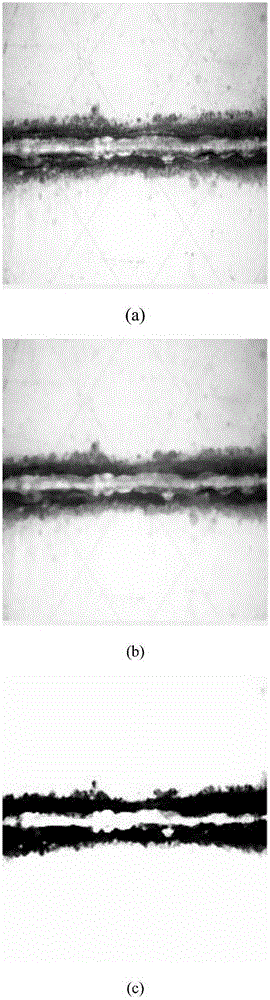

[0052] The image acquisition system includes: an acA2500-14gm industrial camera from Basler, a PCIE-Gie64 image acquisition card from ADLINK, an industrial computer and on-site welding devices. The whole system uses an industrial computer as the main controller, and realizes the image acquisition of the circular saw blade through the embedded PCIE-Gie64 image acquisition card. The digital image to be transferred to the computer, so as to obtain the welding image such as figure 2 (a) shown.

[0053]Step 2. Preprocessing the image;

[0054] In order to suppress the influence of noise, the original image collected by the industrial camera is subjected to noise reduction processing. Smoothing filtering and image contrast enhancement are used for noise reduction processing to eliminate noise interference points, so that the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com