Single-piece discrete type production operation scheduling optimization method

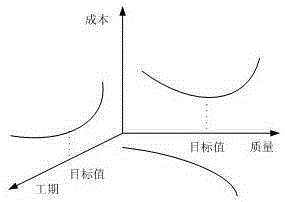

A single-piece discrete and optimized technology, applied in the direction of program control, electrical program control, comprehensive factory control, etc., can solve problems such as the inability to truly achieve lean goals, and achieve the effect of reducing cost losses and uniform solution distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] A method for optimizing the scheduling of single-piece discrete production operations is specifically implemented as follows:

[0047] 1.1 Basic assumptions

[0048] Suppose there is equipment and A workpiece needs to be processed, and a single workpiece contains There is a process sequence constraint between each process. The procedures and processing time of all the workpieces to be processed have been set and cannot be changed; at a time point, only one device can be processed without taking up the processing time of other workpieces, and the processing process is continuous and cannot be stopped; all logistics equipment transportation Cost and efficiency are the same.

[0049] 1.2 Time constraints

[0050]

[0051] (1)

[0052] part number The start time of the first process must be greater than or equal to the first The sum of the start time and processing time of a process.

[0053] 1.3 Equipment Quantity Constraints

[0054]

[0055] 1.4 Uncer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com