MEMS pressure sensor

A pressure sensor and ASIC chip technology, applied in the direction of measuring fluid pressure, instruments, measuring force, etc., can solve the problems affecting the measurement accuracy of the chip, and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below with reference to the drawings and embodiments.

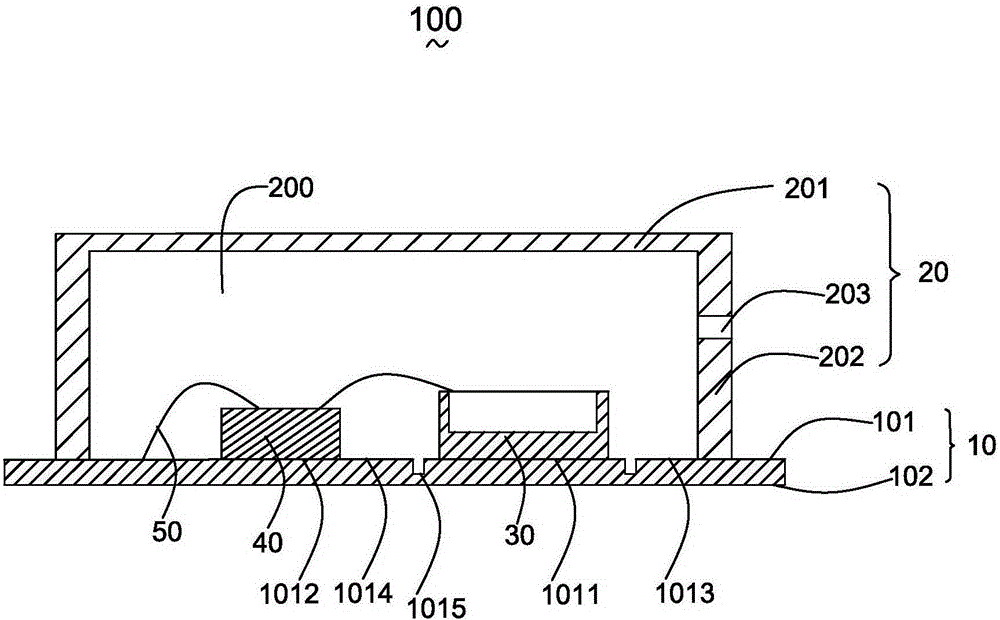

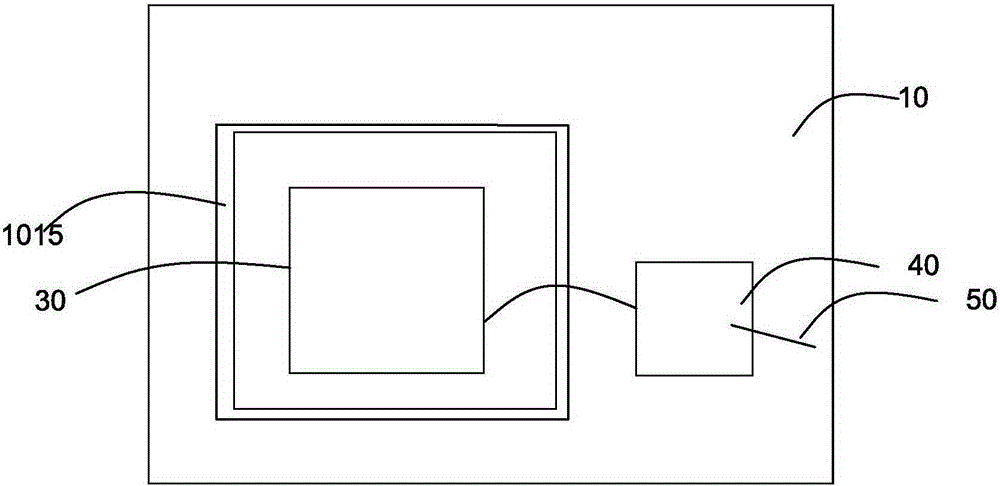

[0015] reference figure 1 with figure 2 , The MEMS pressure sensor 100 provided by the first embodiment of the present invention includes a circuit board 10, a housing 20 covered on the circuit board 10 and combined with the circuit board 10 to form a housing space 200, and a MEMS pressure sensor housed in the housing space 200 Chip 30 and ASIC chip 40. In this embodiment, the MEMS pressure sensor chip 30 and the ASIC chip 40 are arranged on the circuit board 10 side by side and spaced apart, and the electrical connection between the three is achieved by bonding gold wires 50.

[0016] The housing 20 includes a top wall 201 disposed directly opposite to the circuit board 10 and a side wall 202 formed by bending and extending along the edge of the top wall 201. The housing 20 is connected to the circuit board 10 through the side wall 202. The side wall 202 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com