Environment-friendly downhole stratum fracturing method

An environment-friendly, stratigraphic technology, applied in earth-moving drilling, wellbore/well components, production fluids, etc., can solve the problem of low-permeability deep coal seams with great damage, great differences in geological conditions, and complex fracturing facilities and construction processes. and other problems, to achieve the effect of simple equipment assembly and construction, stable and reliable operation process, and improvement of formation permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

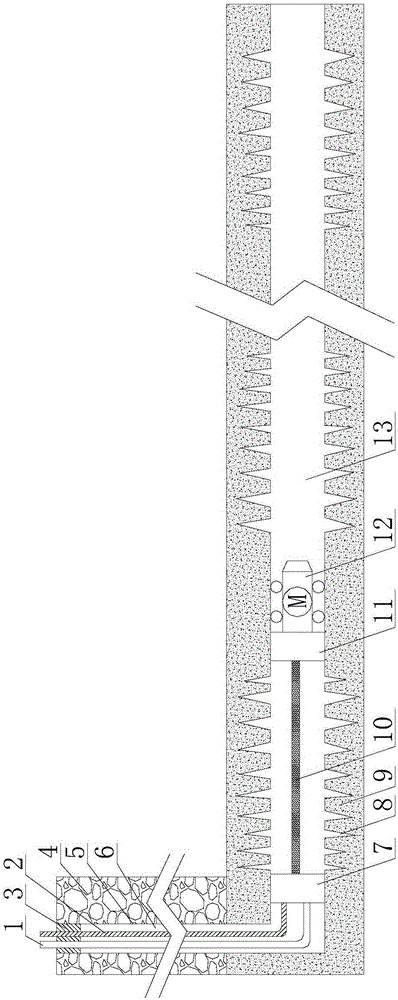

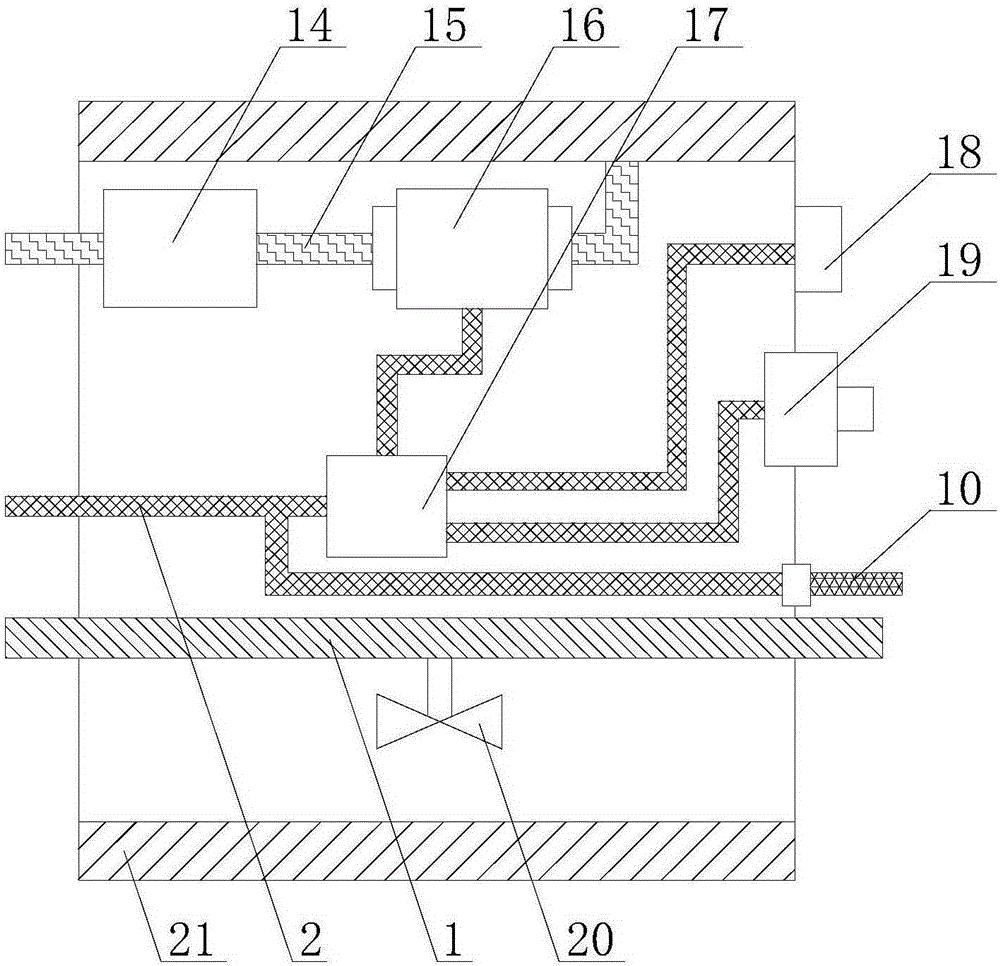

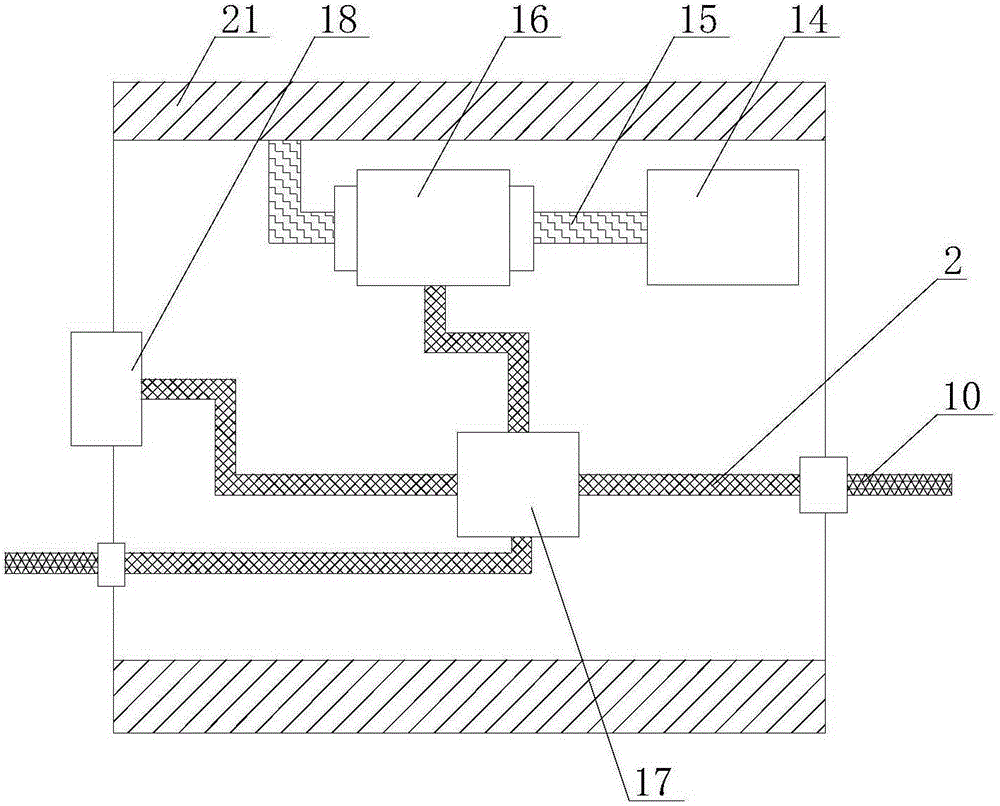

[0023] Embodiment 1. Environment-friendly downhole fracturing formation method

[0024] The environment-friendly downhole fracturing formation method in this example is a cleaning method for downhole fracturing formations that will not pollute the mine and the downhole environment. This method is realized by an environment-friendly downhole fracturing formation device. Figure 1 to Figure 5 joint show, figure 1 It shows the structural schematic diagram of the environment-friendly downhole fracturing formation device of the present invention, figure 2 Shows the sectional structural diagram of the packer I in the well, image 3 Shows the sectional structural diagram of the packer II in the well, in these 3 figures: 1 is the high-pressure hose, 2 is the armored cable in the well, 3 is the wellhead plugging device, 4 is the overlying rock formation, 5 is the well wall, 6 is the wellbore, 7 is the well packer I, 8 is the perforation hole, 9 is the reservoir, 10 is the high-stren...

Embodiment 2

[0025] Embodiment 2. Environment-friendly downhole fracturing formation method

[0026] The environment-friendly underground fracturing formation method in this example is a cleaning method for underground fracturing formations that will not pollute the mine and the underground environment. Figure 1 to Figure 5 etc. have jointly shown that the environmental-friendly downhole fracturing formation method of this example differs from the environmental protection downhole fracturing formation method of Embodiment 1: 1. The composition and composition of the liquid gunpowder injected into the fracturing formation space in this example The formula weight ratio is: combustion agent: oxidant: solvent: sensitizer = 12:75:40:45, the combustion agent is diethylene glycol, and the oxidant is NaNO 3 , the solvent is water, and the sensitizer is sodium nitrite. 2. The injected liquid gunpowder, primary gunpowder, liquid CO 2 The dose-weight ratio formula of the three substances is: liqui...

Embodiment 3

[0027] Embodiment 3. Environment-friendly downhole fracturing formation method

[0028] The environment-friendly underground fracturing formation method in this example is a cleaning method for underground fracturing formations that will not pollute the mine and the underground environment. Figure 1 to Figure 5 etc. have shown that the difference between the environment-friendly downhole fracturing formation method of this example and the environment-friendly downhole fracturing formation method of Embodiment 1 and Embodiment 2 is as follows: 1. The liquid gunpowder injected into the fracturing formation space in this example The components and their formula weight ratios are: combustion agent: oxidant: solvent: sensitizer=7:50:23:22, the combustion agent is urea, and the oxidation agent is KNO 3 , the solvent is water, and the sensitizer is sodium nitrite. 2. The injected liquid gunpowder, primary gunpowder, liquid CO 2 The dose-weight ratio formula of the three substances...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com