A kind of asphalt fume recycling device for road surface heat recycler

A recycling machine and asphalt technology, applied in roads, roads, road repairs, etc., can solve problems such as wasting energy, polluting the environment, and unorganized emissions, and achieve the effects of saving energy, improving competitiveness, and changing unorganized emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

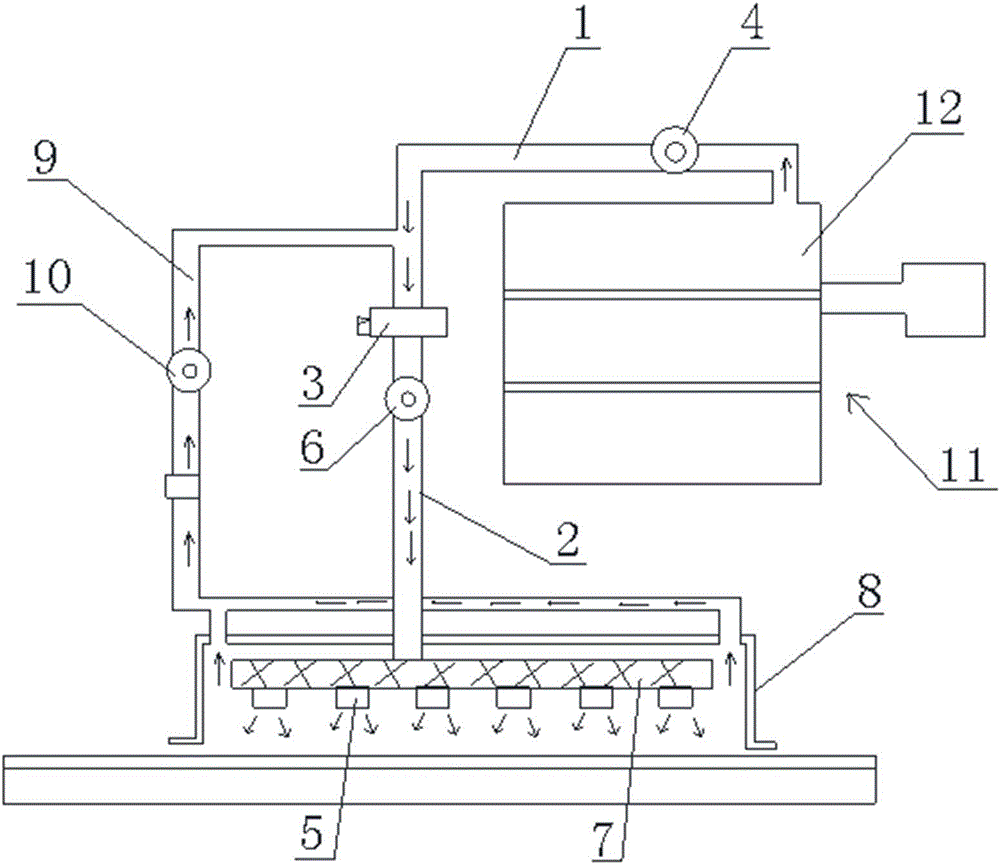

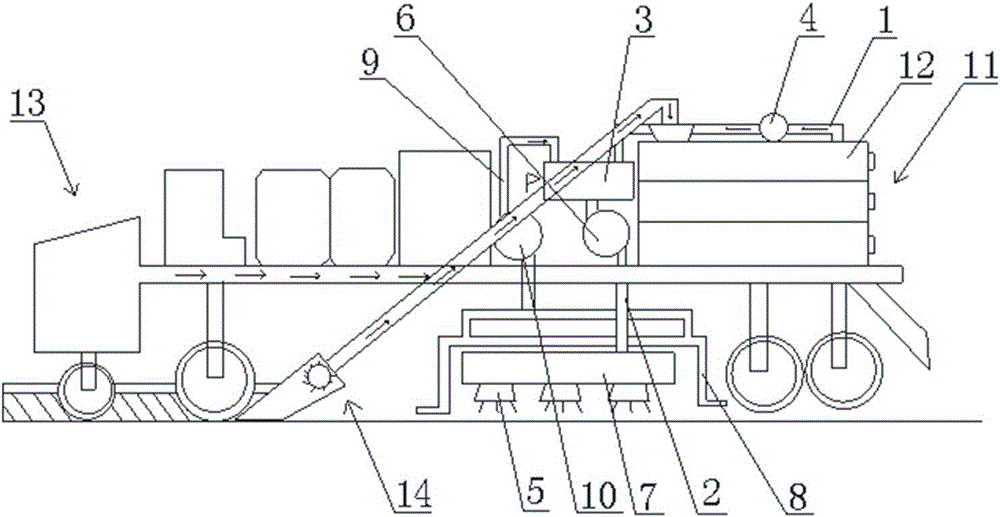

[0015] With reference to the accompanying drawings, an asphalt fume recycling device for a road surface heat regenerator includes a first hot air conveying pipe 1 , a second hot air conveying pipe 2 and a burner 3 . One end of the first hot air delivery pipe 1 is connected to the asphalt smoke outlet, and the other end of the first hot air delivery pipe 1 is connected to the burner 3 . A first blower fan 4 is arranged on the first hot-air delivery pipe 1, and the burner 3 is connected to the road surface heating plate 5 through the second hot-air delivery pipe 2, and a second blower fan 6 and a high-temperature resistant filter7. The road surface heating plates 5 are arranged in multiples, and all of them are distributed at intervals below the high temperature resistant filter 7 . The top of described road surface heating plate 5 is provided with hot air collecting cover 8, and hot air collecting cover 8 connects the 3rd hot blast conveying pipe 9, and the 3rd hot blast conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com